Preparation method of high-efficiency water-based silicon polyether defoaming agent

A polyether defoamer, water-based silicon technology, applied in separation methods, chemical instruments and methods, foam dispersion/prevention, etc. problem, to achieve the effect of increasing the anti-foaming time, excellent anti-foaming and anti-foaming performance, and shortening the anti-foaming time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

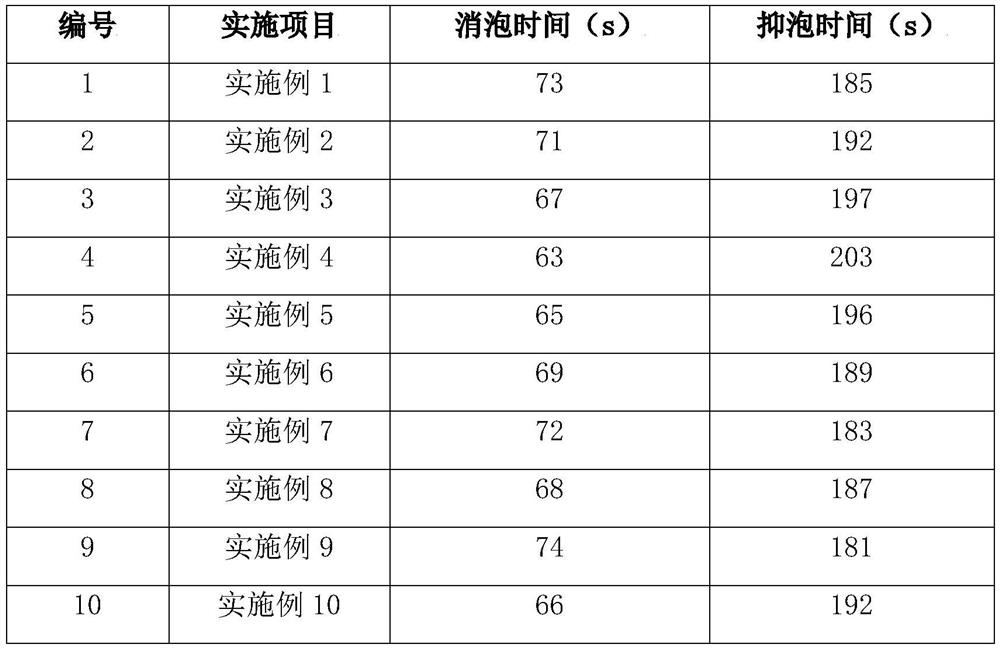

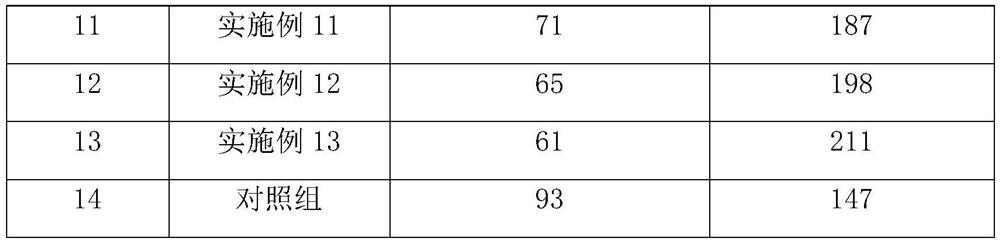

Examples

preparation example Construction

[0030] Specifically, the embodiment of the present invention provides a method for preparing a high-efficiency water-based silicon polyether defoamer, comprising the following steps:

[0031] 1) uniformly mixing polydimethylsiloxane and polyether-modified polysiloxane to obtain mixture A;

[0032] 2) Add mixture A, nonionic surfactant and deionized water into a stirred tank, heat up to 75-80°C, stir for 1-2 hours, then cool down to room temperature to obtain mixture B;

[0033] 3) Add a coupling agent and an emulsifier with a mass percentage of 3% and 5% respectively to the mixture B, and pass nitrogen gas into it, and continue to stir for 20 to 30 minutes to obtain a mixture C;

[0034] 4) Mix the thickener and sodium hydroxide aqueous solution evenly, and adjust the pH to 7 to obtain thickened water;

[0035] 5) Slowly add thickening water to mixture C, the mass ratio of thickening water to mixture C is 1:20, stir at 50-65°C for 1-2 hours, then cool down to room temperature...

Embodiment 1

[0047] Mix polydimethylsiloxane and polyether-modified polysiloxane uniformly in a mass ratio of 1:9 to obtain mixture A; mix mixture A, nonionic surfactant and deionized water in a mass ratio of 1: Add 1:3 into the stirring tank, raise the temperature to 75°C, and stir at a speed of 1000r / min for 2h, then cool down to room temperature to obtain a mixture B; add 3% and 5% titanate coupling agent and polyoxyethylene sorbitan monooleate, and nitrogen gas was introduced, and the stirring was continued for 20 to 30 minutes to obtain mixture C; sodium polyacrylate and 10% sodium hydroxide aqueous solution were mixed evenly, and the pH was adjusted to 7. To obtain thickening water; slowly add thickening water to mixture C, the mass ratio of thickening water to mixture C is 1:20, stir at 55°C for 2h, then cool down to room temperature, homogenize for 0.5h, and homogenize under pressure 100MPa, high-efficiency water-based silicone polyether defoamer.

Embodiment 2

[0049] Mix polydimethylsiloxane and polyether-modified polysiloxane uniformly in a mass ratio of 2:9 to obtain mixture A; mix mixture A, nonionic surfactant and deionized water in a mass ratio of 1: Add 1:3 into the stirring tank, raise the temperature to 75°C, and stir at a speed of 1000r / min for 2h, then cool down to room temperature to obtain a mixture B; add 3% and 5% titanate coupling agent and polyoxyethylene sorbitan monooleate, and nitrogen gas was introduced, and the stirring was continued for 20 to 30 minutes to obtain mixture C; sodium polyacrylate and 10% sodium hydroxide aqueous solution were mixed evenly, and the pH was adjusted to 7. To obtain thickening water; slowly add thickening water to mixture C, the mass ratio of thickening water to mixture C is 1:20, stir at 55°C for 2h, then cool down to room temperature, homogenize for 0.5h, and homogenize under pressure 100MPa, high-efficiency water-based silicone polyether defoamer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com