A food defoamer

A defoamer and food technology, which is applied in the direction of foam dispersion/prevention, chemical instruments and methods, liquid degassing, etc., can solve the problems such as unsatisfactory antifoaming effect of defoamers, affecting food quality, increasing production costs, etc., to achieve Suitable for promotion and use, low production cost, and shortened defoaming time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

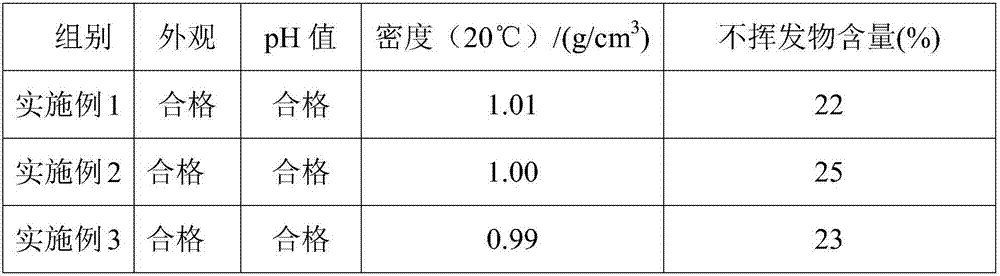

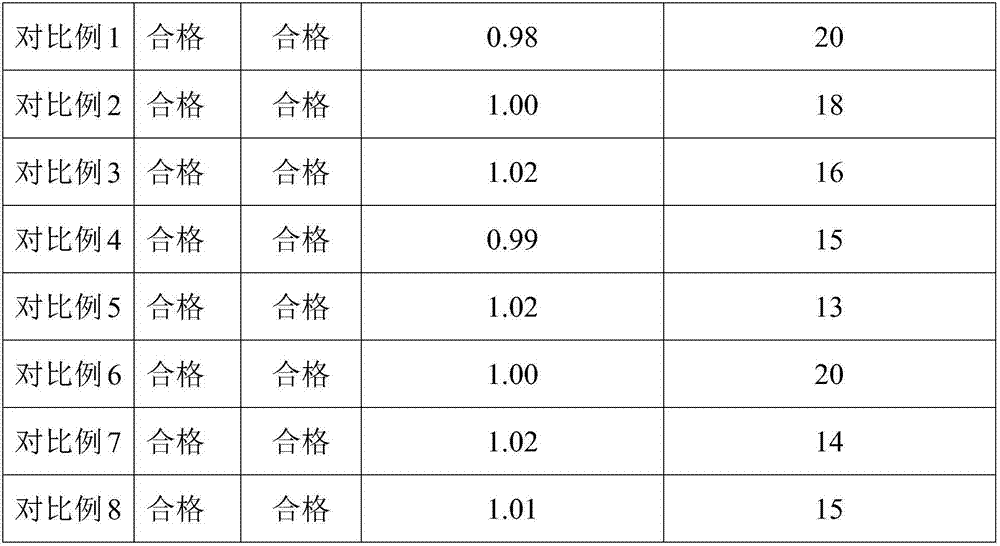

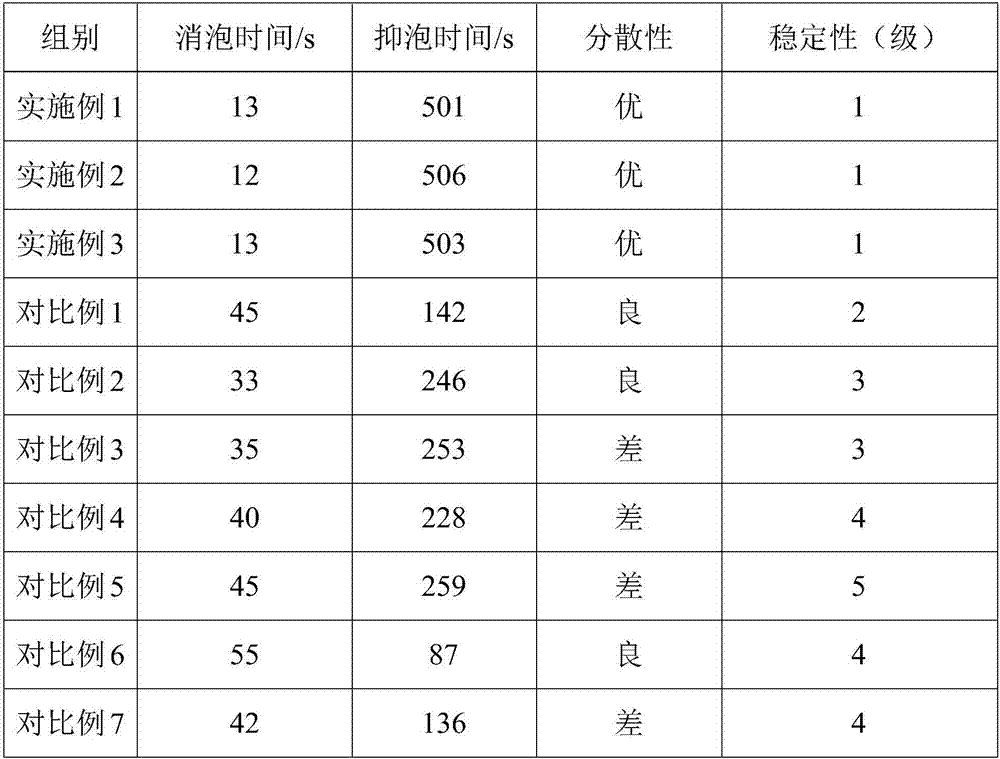

Examples

Embodiment 1

[0025] Embodiment 1, a kind of defoamer for food

[0026] The food defoamer described in Example 1 of the present invention consists of the following components in mass percent: polysiloxane 18%, polyether modified silicone oil 10%, hydrophobic silica 8%, emulsifier 4%, thickener 5% agent, 55% water, the polysiloxane is composed of simethicone oil I with a viscosity of 0.1pa·s, simethicone II with a viscosity of 50pa·s and hydroxyl silicone oil in a weight ratio of 1:0.6:0.5 Ratio composition; Wherein said emulsifier Tween-20 and glyceryl monostearate are formed by the weight ratio of 1:0.5, and described thickener is made up of xanthan gum and chitosan oligosaccharide by the weight ratio of 1:0.4.

[0027] Preparation:

[0028] A) Add polysiloxane and hydrophobic silica into the reaction kettle, stir for 8 minutes, set the stirring speed at 50 rpm, and react at 200°C for 3 hours to obtain a suspension;

[0029] B) Cool the suspension to 90°C, add polyether modified silicone...

Embodiment 2

[0032] Embodiment 2, a kind of defoamer for food

[0033] The food defoamer described in Example 2 of the present invention consists of the following components in mass percent: polysiloxane 20%, polyether modified silicone oil 10%, hydrophobic white carbon black 10%, emulsifier 3%, thickener 4% agent, 53% water, the polysiloxane is composed of simethicone oil I with a viscosity of 0.15pa·s, simethicone II with a viscosity of 58pa·s and hydroxyl silicone oil in a weight ratio of 1:0.6:0.3 Ratio composition; Wherein said emulsifier Tween-20 and glyceryl monostearate are formed by the weight ratio of 1:0.8, and described thickener is made up of xanthan gum and chitosan oligosaccharide by the weight ratio of 1:0.3.

[0034] Preparation:

[0035] A) Add polysiloxane and hydrophobic silica into the reaction kettle, stir for 8 minutes, set the stirring speed at 40 rpm, and react at 180°C for 4 hours to obtain a suspension;

[0036] B) Cool the suspension to 90°C, add polyether mod...

Embodiment 3

[0039] Embodiment 3, a kind of defoamer for food

[0040] The food defoamer described in Example 3 of the present invention consists of the following components in mass percent: polysiloxane 22%, polyether modified silicone oil 6%, hydrophobic white carbon black 12%, emulsifier 5%, thickener 6% of agent and 49% of water, the polysiloxane is composed of simethicone oil I with a viscosity of 1pa·s, simethicone II with a viscosity of 55pa·s and hydroxyl silicone oil in a weight ratio of 1:0.8:0.3 Composition; Wherein said emulsifier Tween-20 and glyceryl monostearate are formed by the weight ratio of 1:1, and described thickener is made up of xanthan gum and chitosan oligosaccharide by the weight ratio of 1:0.5.

[0041] The preparation method refers to Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com