Defoaming method in synthesizing process of polyamide resin

A technology of polyamic acid resin and synthesis process, which is applied in the direction of foam dispersion/prevention, and can solve problems such as abnormal production continuity, defects in manufactured products, and high viscosity, and achieve shortened defoaming time, reduced defoaming time, and improved color uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

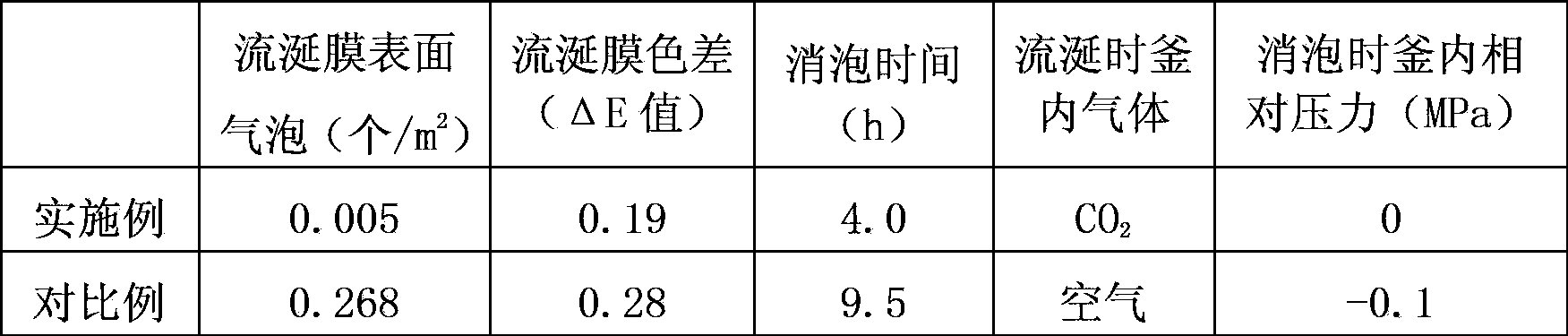

Examples

Embodiment Construction

[0017] The defoaming method embodiment of this polyamic acid resin synthetic process comprises the steps:

[0018] Ⅰ. Heat and stir slowly

[0019] After the synthesis reaction, the polyamic acid resin solution is pressed in from the reaction kettle through the feed nozzle above the tank body of the defoaming kettle. Flat, or 10mm higher than the highest point of the spiral blade. A heated medium is passed into the jacket of the defoaming kettle, or a heated heat-conducting medium can also be passed into the hollow heat-conducting medium pipe of the spiral blade to heat the polyamic acid resin solution in the kettle, and the temperature is kept at 70°C. The stirring rate is 50r / min; maintain for 1 hour; change the stirring direction every 20 minutes, alternately stirring clockwise and counterclockwise;

[0020] Ⅱ. Heating and rapid stirring

[0021] Keep the temperature unchanged, increase the stirring speed to 80r / min; change the stirring direction every 20 minutes; keep h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com