Defoaming agent suitable for curtain coating of mirror back coating, preparation method of defoaming agent and mirror back coating

A technology of defoaming agent and spray-coated mirror, applied in the direction of coating, etc., can solve the problems such as the need to improve the anti-foaming performance, the broken screen, the poor quality of the mirror back coating, so as to reduce the broken screen phenomenon and reduce the bubbles on the board surface , the effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

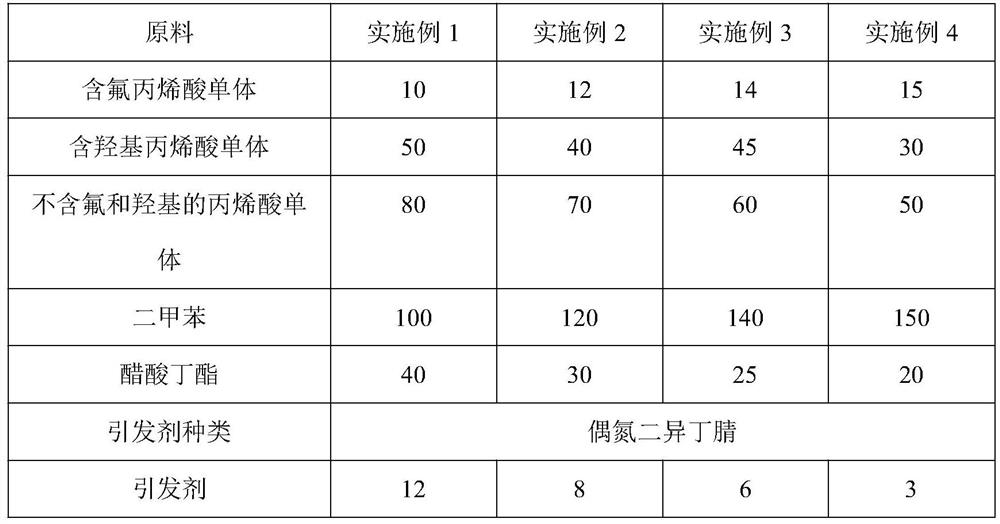

[0042] A kind of defoamer suitable for curtain coating mirror back coating, its raw material content is shown in table 1.

[0043] Wherein, the fluorine-containing acrylic acid monomer is trifluoroethanol acrylate;

[0044] The hydroxyl-containing acrylic acid monomer is hydroxypropyl acrylate;

[0045] The acrylic monomer without fluorine and hydroxyl is butyl acrylate;

[0046] The initiator is azobisisobutyronitrile (AIBN).

[0047] A kind of preparation method that is applicable to the defoamer of curtain coating mirror back coating, it comprises the following steps:

[0048]Add xylene and butyl acetate into the reaction kettle, stir until mixed evenly, and then raise the temperature to 100°C to obtain Mixture I; add fluorine-containing acrylic monomer, hydroxyl-containing acrylic monomer, , the initiator is added in the mixer, and stirred until it is evenly mixed to obtain the mixture II;

[0049] Under the condition of heat preservation, add the mixture II to the mix...

Embodiment 2-4

[0051] Embodiment 2-4 is applicable to the defoamer of coating mirror back coating, and its difference with embodiment 1 is:

[0052] The types and contents of the raw materials of the defoamer are different, and the contents of the raw materials are shown in Table 1;

[0053] Among the types of raw materials: the fluorine-containing acrylic monomer in Example 2 is trifluoroethyl methacrylate, and the hydroxyl-containing acrylic monomer is hydroxyethyl methacrylate; the fluorine-containing acrylic monomer in Example 3 is pentafluoropropyl acrylate 1. The hydroxyl-containing acrylic acid monomer is hydroxypropyl acrylate; the fluorine-containing acrylic monomer of embodiment 4 is a mixture of pentafluoropropyl acrylate and methacrylate-free fluorine-free propyl ester, and the two are mixed in equal amounts; the hydroxyl-containing acrylic monomer is Hydroxypropyl methacrylate and hydroxyethyl acrylate mixed in equal amounts;

[0054] All the other are identical with embodiment...

Embodiment 5

[0056] A kind of defoamer that is applicable to the mirror back coating of flow coating, its difference with embodiment 2 is that the content of hydroxyl-containing acrylic acid monomer is 40.5kg, all the other are the same as embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com