Cooling liquid used in cutting process, preparation method and application thereof

A technology of cooling liquid and mixed liquid, applied in lubricating composition, energy waste water treatment, petroleum industry, etc., can solve the problems of unavoidable adverse effects of defoamer, easy aggregation into viscous colloid, easy aggregation and contamination, etc. Eliminate adverse effects, facilitate recycling and reuse, and reduce overall costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

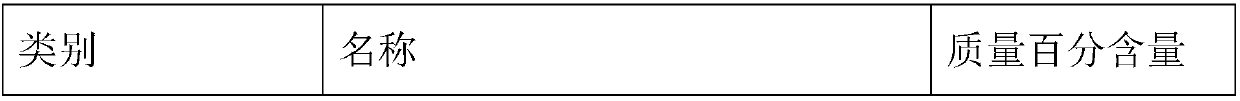

[0045] The invention provides a cooling liquid used in the cutting process, the cooling liquid includes the following components by mass percentage:

[0046]

[0047]

[0048] Its preparation method is as follows:

[0049] Mix the formula amount of 1-decyne-3,7-diol polyoxyethylene ether, polyvinylpyrrolidone K25 and deionized water to obtain the first mixed liquid; dissolve oxalic acid in deionized water and stir to obtain the second Two mixed liquids; mixing the first mixed liquid and the second mixed liquid, adjusting the pH value to 6.5 to obtain the cooling liquid.

Embodiment 2

[0051] The present invention provides a cooling liquid used in the cutting process. The difference between the formula of the cooling liquid and the formula in Example 1 is that 1-decyne-3,7-diol polyoxyethylene ether is replaced by 1-octyne -3,7-diol polyoxyethylene ether, the rest remain unchanged.

[0052] Its preparation method is identical with embodiment 1.

Embodiment 3

[0054] The present invention provides a cooling liquid used in the cutting process. The difference between the formula of the cooling liquid and the formula in Example 1 is that 1-decyne-3,7-diol polyoxyethylene ether is replaced by 1-nonyne -3,7-diol polyoxyethylene ether, the rest remain unchanged.

[0055] Its preparation method is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com