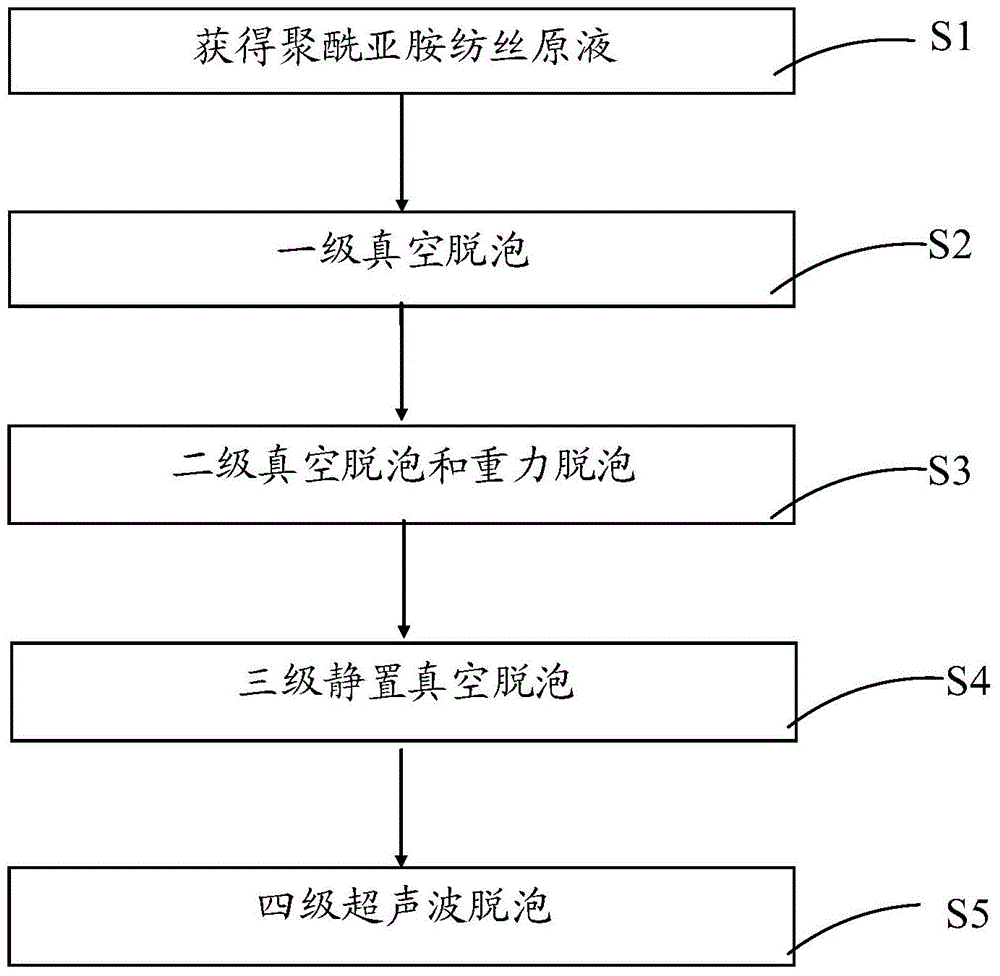

Deaeration method of polyimide spinning solution and device thereof

A technology of polyimide spinning and spinning solution, applied in the direction of foam dispersion/prevention, can solve the problems of low production capacity, large floor space, low defoaming efficiency, etc., achieving low cost, easy operation, Complete deaeration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

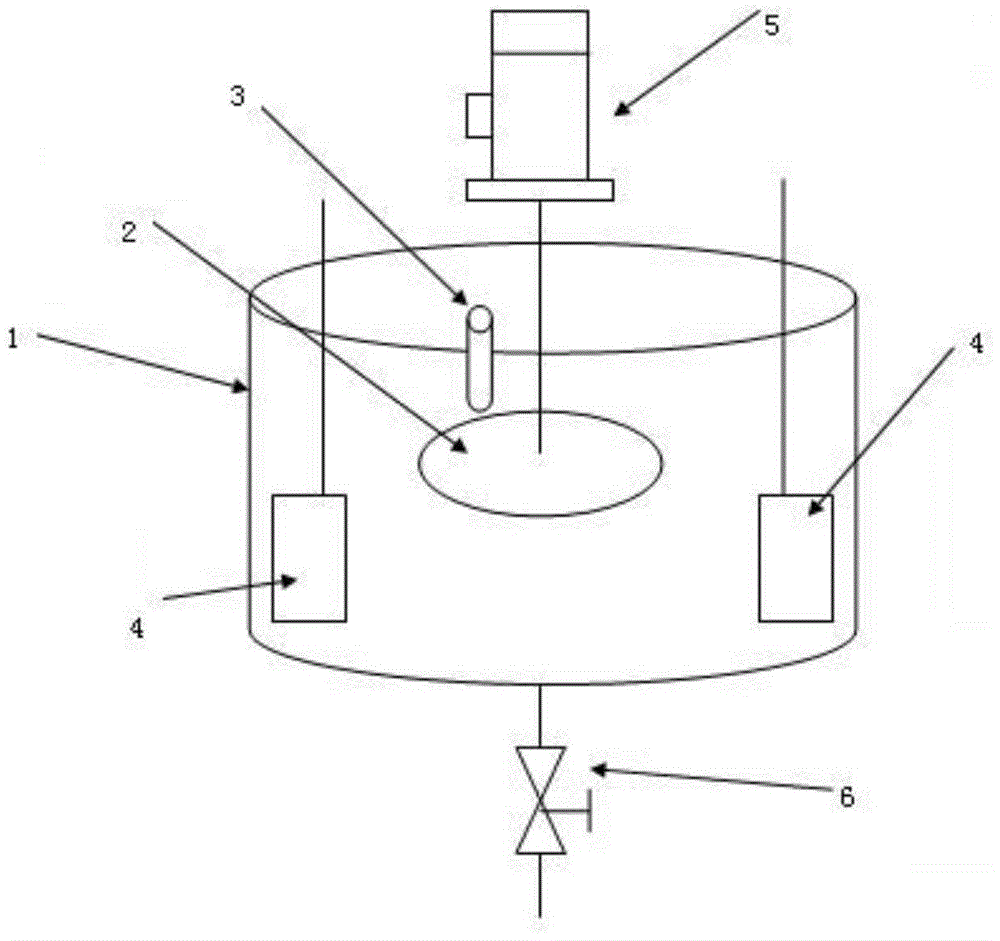

Method used

Image

Examples

Embodiment 1

[0043] S11, start the vacuum system, and set the vacuum degree to -90kPa~-98kPa; start the cooling water circulation system, so that the temperature in the defoaming kettle is cooled to 5°C; start the centrifugal module, so that the speed of the defoaming spinner is 550r / min;

[0044] S12, first-level degassing: start the feeding pump and mass flow meter, and continuously inject 100L polyimide spinning stock solution with a dynamic viscosity of 80000Pa.s into the degassing kettle at a feeding rate of 200L / h through the filter device On the spinning disc running at high speed inside, the spinning solution is dispersed and thrown out to the surroundings under the action of centrifugal force, forming a film-like spinning solution layer, which will be broken rapidly in a vacuum environment Part of the bubbles, complete the first-level degassing;

[0045] S13, two-stage gravity defoaming: the spinning solution obtained in step S12 is evenly flung onto the wall of the kettle under t...

Embodiment 2

[0054] S21, start the vacuum system, and set the vacuum degree to -90kPa~-98kPa; start the cooling water circulation system, so that the temperature in the defoaming kettle is cooled to 5°C; start the centrifugal module, so that the speed of the defoaming spinner is 550r / min;

[0055] S22, first-level defoaming: start the feeding pump and mass flow meter, pass 100L of polyimide spinning stock solution with a dynamic viscosity of 120000Pa. Put it into the high-speed rotating disc in the defoaming kettle, and under the action of centrifugal force, the spinning solution will be dispersed and thrown out to form a film-like spinning solution layer, which is in a vacuum environment. Part of the air bubbles will be rapidly broken down, and the first-level degassing will be completed;

[0056] S23, two-stage gravity defoaming: the spinning solution obtained in step S12 is evenly flung onto the wall of the kettle under the action of centrifugal force, and then flows down to the bottom ...

Embodiment 3

[0065] S31, start the vacuum system, set the vacuum degree to -90kPa~-98kPa; start the cooling water circulation system, so that the temperature in the defoaming kettle is cooled to 5°C; start the centrifugal module, so that the speed of the defoaming spinner is 550r / min;

[0066] S32, first-level defoaming: start the feeding pump and mass flow meter, pass 100L of polyimide spinning stock solution with a dynamic viscosity of 160000Pa. Put it into the high-speed rotating disc in the defoaming kettle, and under the action of centrifugal force, the spinning solution will be dispersed and thrown out to form a film-like spinning solution layer, which is in a vacuum environment. Part of the air bubbles will be rapidly broken down, and the first-level degassing will be completed;

[0067] S33, two-stage gravity defoaming: the spinning solution obtained in step S12 is evenly flung onto the wall of the kettle under the action of centrifugal force, and then flows down the wall of the ke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com