A kind of food defoamer and preparation method thereof

A technology for defoaming agent and food, applied in separation methods, chemical instruments and methods, foam dispersion/prevention, etc., can solve the problems of bitter taste of antifoaming agent, causing product taste and sales volume, and bitterness of products, etc. Excellent taste, stable product, long foam suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

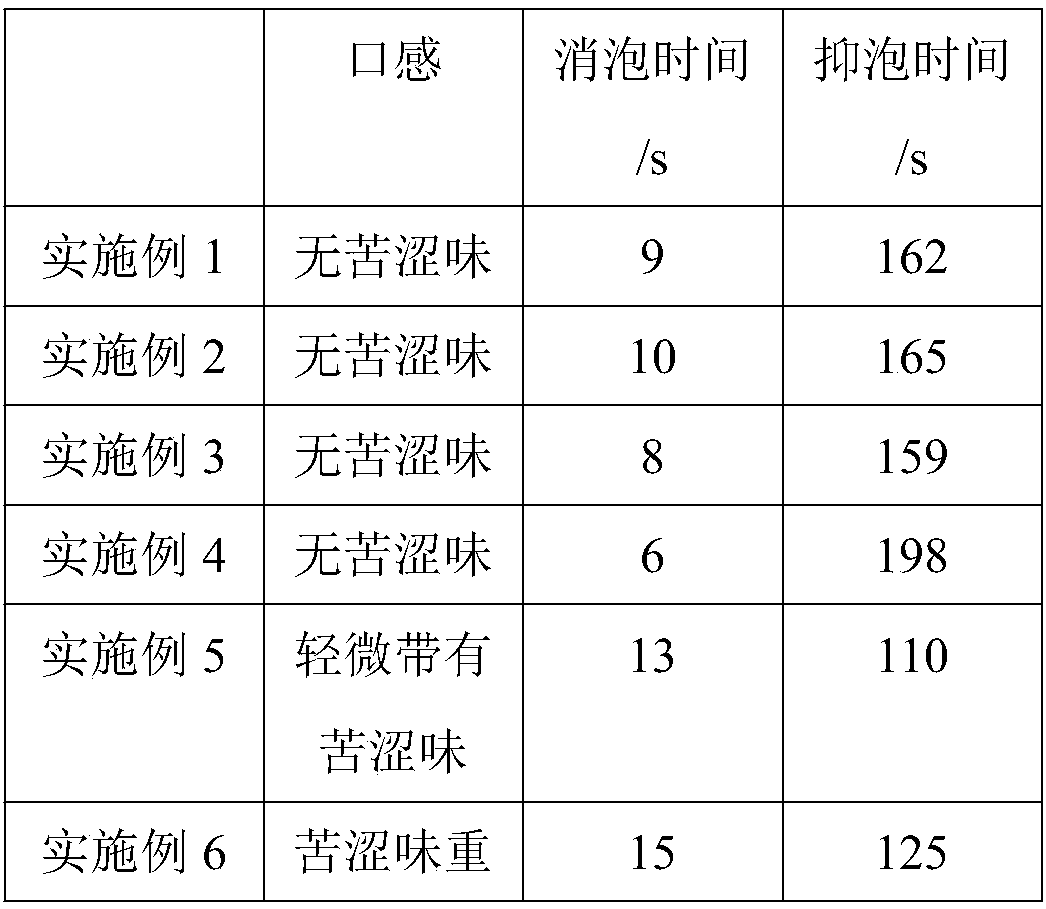

Examples

Embodiment 1

[0017] A preparation method of a food defoamer, said method comprising the steps of: (1) adding 70kg of simethicone oil to an electric heating kettle, and then turning on an electric heating switch to heat up; (2) said simethicone oil When the temperature is raised to 80°C, 3kg of silicon dioxide is evenly added to the upper port of the electric heating kettle, and then the temperature is continued to rise to 190°C, and the temperature is kept constant to allow the dimethyl silicone oil and silicon dioxide to react for 1.5 hours, wherein the heating rate is 5°C / min; (3) After the constant temperature reaction, stop heating and let the electric heating kettle cool naturally to 170°C, transfer the reacted solution in the electric heating kettle to the steam heating kettle, maintain the solution temperature in the steam heating kettle at 150°C, and stir sequentially Add 18kg of glycerol polyether, 22kg of Span, and 12kg of Tween, and let it react in a steam heating kettle for 2h; ...

Embodiment 2

[0020] A preparation method of a food defoamer, characterized in that the method comprises the steps of: (1) adding 90kg of simethicone oil to an electric heating kettle, and then turning on an electric heating switch to heat up; (2) When the simethicone oil is heated to 80°C, add 5kg of silicon dioxide evenly to the top of the electric heating kettle, then continue to heat up to 210°C, keep the temperature constant, and let the simethicone oil and silicon dioxide react for 4 hours, and the heating rate is 5°C / min; (3) When the temperature of the electric heating kettle is lowered to 170°C after the constant temperature reaction is over, the solution after the reaction in the electric heating kettle is transferred into the steam heating kettle, and the solution temperature in the steam heating kettle is maintained at 165°C, while While stirring, add 23kg of glycerol polyether, 28kg of Span, and 18kg of Tween in turn, and let it react in the steam kettle for 3h; (4) after the r...

Embodiment 3

[0023] A kind of preparation method of food defoamer, it is characterized in that, described method comprises the steps: (1) add the simethicone oil of 80kg in electric heater, turn on electric heating switch to heat up then; (2) described When the simethicone oil is heated to 80°C, add 4kg of silicon dioxide evenly to the top of the electric heating kettle, then continue to heat up to 200°C, keep the temperature constant, and let the simethicone oil and silicon dioxide react for 4 hours, and the heating rate is 5°C / min; (3) When the temperature of the electric heating kettle is lowered to 170°C after the constant temperature reaction is over, the solution after the reaction in the electric heating kettle is transferred into the steam heating kettle, and the solution temperature in the steam heating kettle is maintained at 165°C, while Add 20kg of glycerol polyether, 25kg of Span, and 15kg of Tween in sequence while stirring, and let it react in the steam kettle for 3h; (4) Af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com