Method for efficient and quick determination of defoaming property of water-based paint

A water-based paint, rapid measurement technology, applied in measuring devices, analytical materials, instruments, etc., can solve problems such as unfavorable paint testing, affecting production progress, and long testing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

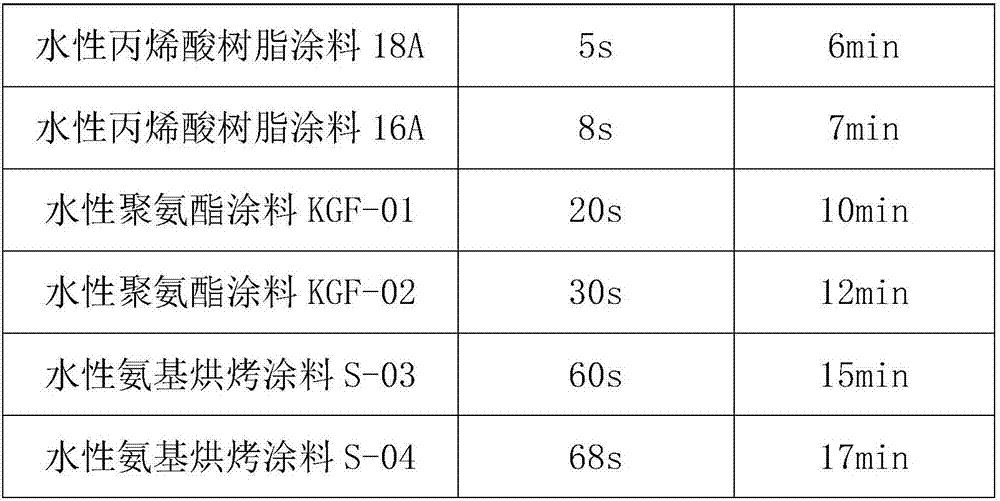

[0021] Adopt the method of the present invention to measure respectively water-based acrylic resin coating 18A, water-based acrylic resin coating 16A, water-based polyurethane coating KGF-01, water-based polyurethane coating KGF-02, water-based amino baking coating S-03 and water-based amino baking coating S-04 The defoaming properties of:

[0022] Step 1, weigh 20g of water-based acrylic resin paint 18A and pour it into No. 1 jar, weigh 20g of water-based acrylic resin paint 16A and pour it into No. 2 jar, weigh 20g of water-based Polyurethane coating KGF-01 and pour it into No. 3 jar, weigh 20g of water-based polyurethane coating KGF-02 and pour it into No. 4 jar, weigh 20g of water-based amino baking coating S- 03 and pour it into a No. 5 jar, weigh 20g of water-based amino baking coating S-04 and pour it into a No. 6 jar;

[0023] Step 2, inject water into the No. 1 jar at a height of 35 cm from the liquid level in the No. 1 jar, and the water-based acrylic resin coating ...

Embodiment 2

[0030] The traditional stirring method was used to measure the water-based acrylic resin coating 18A, water-based acrylic resin coating 16A, water-based polyurethane coating KGF-01, water-based polyurethane coating KGF-02, water-based amino baking coating S-03 and water-based amino baking coating S-04. Defoaming properties:

[0031] Step 1. Weigh 20g of water-based acrylic resin paint 18A and pour it into No. 1 blender, weigh 20g of water-based acrylic resin paint 16A and pour it into No. 2 blender, weigh 20g of water-based polyurethane paint KGF- 01 and pour it into blender No. 3, weigh 20g of water-based polyurethane coating KGF-02 and pour it into blender No. 4, weigh 20g of water-based amino baking paint S-03 and pour it into No. 5 In the blender, weigh 20g of water-based amino baking coating S-04 and pour it into No. 6 blender;

[0032] Step 2, above-mentioned six stirrers all carry out the stirring of 800r / min for 10 minutes;

[0033] Step 3, record the time that the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com