Graphene oxide modified organic silicon defoamer and preparation method thereof

An organosilicon defoamer and graphene modification technology, applied in chemical instruments and methods, separation methods, foam dispersion/prevention, etc., can solve problems such as low defoaming efficiency, long defoaming time, and unfavorable use. , to achieve the effect of moderate price, short time and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

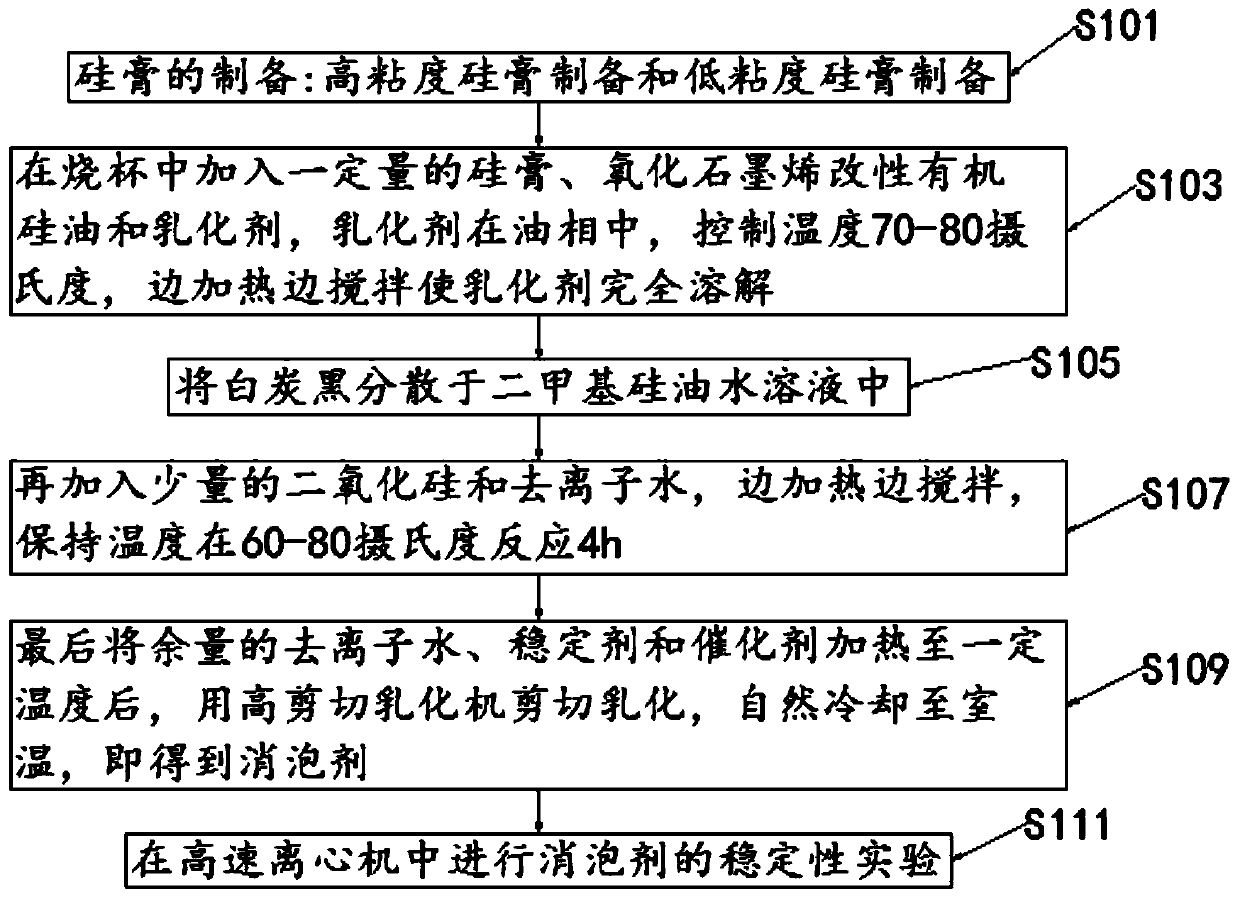

Method used

Image

Examples

Embodiment 1

[0033] A graphene oxide modified silicone defoamer, comprising the following percentages of raw materials: graphene oxide modified silicone oil 5%, dimethyl silicone oil 14%, silicon dioxide 5%, polyether 8%, emulsifier 7 %, catalyst 0.1%, stabilizer 2%, deionized water 50%, fixed high-viscosity silicone paste 3%, low-viscosity silicone paste 2% and white carbon black 3.9%.

Embodiment 2

[0035] A graphene oxide modified silicone defoamer, comprising the following percentages of raw materials: graphene oxide modified silicone oil 5%, dimethyl silicone oil 12%, silicon dioxide 3%, polyether 8%, emulsifier 6 %, catalyst 0.1%, stabilizer 2%, deionized water 55%, fixed high-viscosity silicone paste 3%, low-viscosity silicone paste 2% and white carbon black 3.9%.

Embodiment 3

[0037] A graphene oxide modified silicone defoamer, comprising the following percentages of raw materials: graphene oxide modified silicone oil 5%, dimethyl silicone oil 10%, silicon dioxide 3%, polyether 7%, emulsifier 5 %, catalyst 0.1%, stabilizer 1%, deionized water 60%, fixed high-viscosity silicone paste 3%, low-viscosity silicone paste 2% and white carbon black 3.9%.

[0038] Optionally, the stabilizer includes a thickener and a preservative, the thickener is sodium hydroxymethylcellulose, alginic acid derivatives and polyvinyl alcohol, and the preservative is sodium benzoate.

[0039] Optionally, the emulsifier is a mixture of sorbitan fatty acid ester, sorbitan monostearate and polyoxyethylene sorbitan monostearate, and the ratio of the three It is 0.5:1.2:1.3.

[0040] Optionally, the fixed high-viscosity silicone paste and the low-viscosity silicone paste are mixtures of simethicone and silicon dioxide in different proportions.

[0041] Optionally, the simethicone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com