A kind of preparation method of medicinal hydroxypropyl starch capsule

A technology of hydroxypropyl starch and capsules, which is applied in the field of preparation of starch-based capsules. It can solve the problems of high equipment requirements, long time consumption, and the production of microorganisms, and achieve high transparency, short defoaming time, and few reaction by-products. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

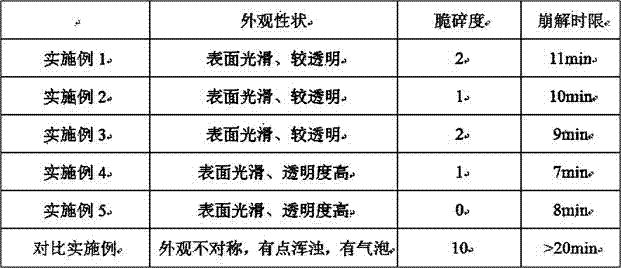

Examples

Embodiment 1

[0027] (1) Starch etherification: After blending propylene oxide and catalyst in the dispersion medium, add food-grade starch. The ratio of the volume of propylene oxide to the mass of starch is 1.5ml: 1.0g, and keep stirring to make it fully react.

[0028] (2) Preparation of starch slurry glue: add water to the sol tank, raise the temperature to 30°C, add the starch glue prepared in step (1), raise the temperature to 50°C, add a reinforcing agent, and stir to obtain the starch slurry glue;

[0029] (3) Defoaming and impurity removal: Add 2 times the volume of ethanol to the starch slurry and wash it 3 times to remove unreacted by-products such as propylene oxide and propylene glycol, and finally add ethanol and let it stand for a while until the glue is removed. Discard after soaking completely;

[0030] (4) Capsule preparation: the defoamed starch slurry glue solution in the above step (3) is prepared by a conventional dipping method to obtain a starch hollow capsule;

Embodiment 2

[0032] (1) Starch etherification: After blending propylene oxide and catalyst in the dispersion medium, add food-grade starch. The ratio of the volume of propylene oxide to the mass of starch is 2ml: 1.0g, and keep stirring to make it fully react.

[0033] (2) Preparation of starch paste glue: add water to the sol tank, raise the temperature to 35°C, add the starch glue prepared in step (1), heat up to 55°C, add a reinforcing agent, and stir to obtain the starch paste glue;

[0034] (3) Defoaming and impurity removal: Add 3 times the volume of ethanol to the starch slurry and wash it 4 times to remove by-products such as unreacted propylene oxide and propylene glycol, and finally add ethanol and let it stand for a period of time until the glue is removed. Discard after soaking completely;

[0035] (4) Capsule preparation: the defoamed starch slurry glue solution in the above step (3) is prepared by a conventional dipping method to obtain a starch hollow capsule;

Embodiment 3

[0037] (1) Starch etherification: After blending propylene oxide and catalyst in the dispersion medium, add food-grade starch. The ratio of the volume of propylene oxide to the mass of starch is 2.5ml: 1.0g. Stir continuously to make it fully react.

[0038] (2) Preparation of starch paste glue: add water to the sol tank, raise the temperature to 40°C, add the starch glue prepared in step (1), heat up to 50°C, add a reinforcing agent, and stir to obtain the starch paste glue;

[0039] (3) Defoaming and impurity removal: Wash the starch slurry glue with 3 times the volume of ethanol for 5 times to remove unreacted by-products such as propylene oxide and propylene glycol, and finally add ethanol and let stand for a period of time until the glue is detached. Discard after soaking completely;

[0040] (4) Capsule preparation: the defoamed starch slurry glue solution in the above step (3) is prepared by a conventional dipping method to obtain a starch hollow capsule;

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com