Antifungal anti-mite textile material and preparation method thereof

A textile material and anti-fungal technology, applied in textiles and papermaking, biochemical fiber treatment, fiber type, etc., can solve problems such as short service life, weak functionality, and limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

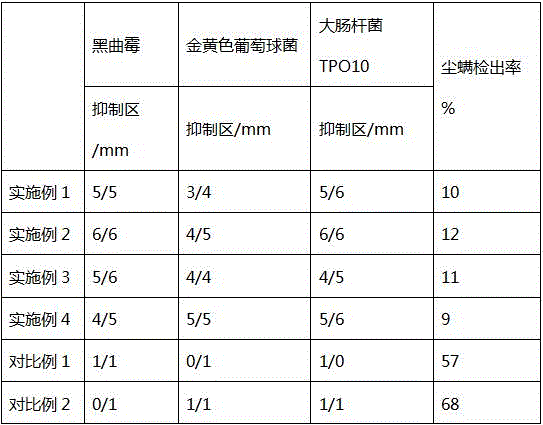

Examples

preparation example Construction

[0010] A kind of preparation method of the antifungal and dust mite textile material, comprises the following steps:

[0011] (1) Weigh each raw material according to parts by weight;

[0012] (2) Mix polyester fiber, polyester fiber, nylon fiber, bamboo fiber, polylactic acid fiber and acetate fiber into 10% ethanol solution, keep warm and activate for 1.5-3 hours;

[0013] (3) Mix kapok, cotton, sisal, flax and chitin into 5% boric acid solution, use an ultrasonic pulverizer, and ultrasonically pulverize for 30-60 minutes;

[0014] (4) Mix the solution of step (2) and step (3), add it to the reaction kettle, and then add azadirachtin, chloroacetic acid, p-phenylenediamine, castor oil bis-hydroxypropyl polydimethylmethanone to the mixed solution in sequence siloxane ester, monoisotridecyl phosphate, stirred for 30-60 minutes, and the stirring speed was 1000 rpm;

[0015] (5) Add dispersant and wetting agent to the reaction kettle in turn, then heat the reaction ...

Embodiment 1

[0026] (1) Weigh 20 parts of polyester fiber, 20 parts of polyester fiber, 15 parts of nylon fiber, 15 parts of bamboo fiber, 15 parts of polylactic acid fiber, 15 parts of acetate fiber, 25 parts of kapok, 15 parts of cotton, sisal 15 parts, 15 parts of flax, 10 parts of chitin, 5 parts of azadirachtin, 5 parts of chloroacetic acid, 2 parts of p-phenylenediamine, 2 parts of castor oil bis-hydroxypropyl polydimethylsiloxane, monophosphate 2 parts of isotridecyl ester, 5 parts of taurate, 5 parts of methyl pyroglutamate and 5 parts of 5-chlorosalicylamide;

[0027] (2) Mix polyester fiber, polyester fiber, nylon fiber, bamboo fiber, polylactic acid fiber and acetate fiber into 10% ethanol solution, keep warm and activate for 1.5 hours, and keep warm at 50°C;

[0028] (3) Mix kapok, cotton, sisal, flax and chitin into 5% boric acid solution, use ultrasonic pulverizer, ultrasonic pulverize for 30 minutes, the power of ultrasonic pulverizer is 150W;

[0029] (4) Mix the s...

Embodiment 2

[0035] (1) Weigh 30 parts of polyester fiber, 30 parts of polyester fiber, 20 parts of nylon fiber, 20 parts of bamboo fiber, 20 parts of polylactic acid fiber, 20 parts of acetate fiber, 20 parts of kapok, 20 parts of cotton, sisal 20 parts, 20 parts of flax, 15 parts of chitin, 6 parts of azadirachtin, 6 parts of chloroacetic acid, 3 parts of p-phenylenediamine, 3 parts of castor oil bis-hydroxypropyl polydimethylsiloxane, monophosphate 3 parts of isotridecyl ester, 3 parts of aminoguanidine sulfonate, 6 parts of silicon grease ethyl ester and 6 parts of guinellactam;

[0036] (2) Mix polyester fiber, polyester fiber, nylon fiber, bamboo fiber, polylactic acid fiber and acetate fiber into 10% ethanol solution, keep warm for 2 hours, and keep warm at 60°C;

[0037] (3) Mix kapok, cotton, sisal, flax and chitin into 5% boric acid solution, use ultrasonic pulverizer, ultrasonic pulverize for 40 minutes, the power of ultrasonic pulverizer is 180W;

[0038] (4) Mix the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com