Surface modification method for lossless environment-friendly convenient aramid fiber material

A surface modification, aramid fiber technology, applied in the field of aramid material surface modification, can solve the problems of complex equipment, poor modification effect, complicated operation steps, etc., and achieve the effect of adjustable thickness and excellent reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

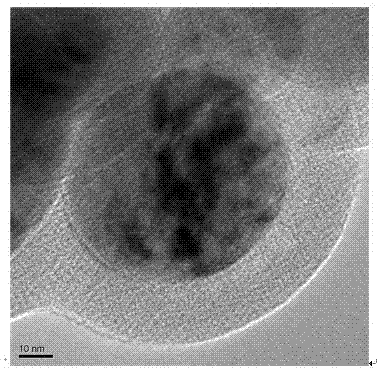

[0016] Modification of aromatic fiber powder

[0017] The mass percentage content of each component: Measure 200 ml of Tris-HCl buffer (pH=9.0) and place it in a 500 ml flask, add 6.0 g of aramid fiber powder, and add 0.4 g of dopamine hydrochloride powder, open Magnetic stirrer, react in air for 5 h. Put the reacted suspension into a centrifuge tube, centrifuge in a TGL-16G high-speed centrifuge, remove the lower solid powder, rinse with distilled water, centrifuge again, and repeat the centrifuge and rinse with distilled water until the centrifuge supernatant is colorless, and finally The obtained lower modified aromatic fiber powder is put into an oven and dried at 40 °C to obtain modified 5h aromatic fiber powder. The same method can obtain modified 24h aromatic fiber powder. The TEM picture of the modified 5h aromatic fiber powder obtained is as follows figure 2 。

Embodiment 2

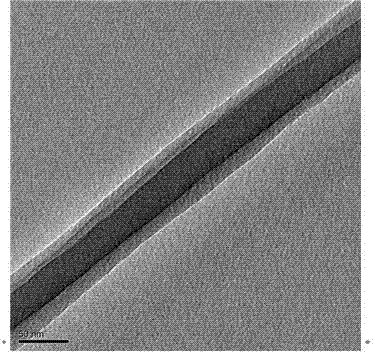

[0019] Aramid long fiber Modification of

[0020] Measure 200 ml of Tris-HCl buffer solution (pH=7.4) into a 500 ml beaker, and add 0.4 g of dopamine hydrochloride powder to prepare a solution. After placing the aramid filament in the above solution for 3 minutes, take it out and let the air flow down and react for 2 minutes. After repeating this process 6 times, the obtained modified aramid long fibers are washed with distilled water, and then placed in an oven to be dried at 40 °C to obtain modified aramid long fibers. The TEM picture of the product is as figure 1 .

Embodiment 3

[0021] Example 3 Modification of Aramid Chopped Fiber

[0022] Measure 400 ml of Tris-HCl buffer (pH=10.8) and place it in a round bottom flask, add 6.0 g of aramid chopped fiber, and 0.8 g of dopamine hydrochloride powder, turn on the magnetic stirrer, and react for 24 hours. The modified aramid chopped fiber was taken out, washed with distilled water, and dried in an oven at 40 °C to obtain the modified aramid chopped fiber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com