Rubber antiager and method for preparing same

A technology of rubber anti-aging agent and anti-aging agent, which is applied in the direction of zinc organic compounds, can solve the problems of affecting long-term performance, unfavorable transportation, processing and storage, and product pollution, so as to improve long-term protection performance, improve discoloration and migration performance, The effect of excellent anti-aging properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

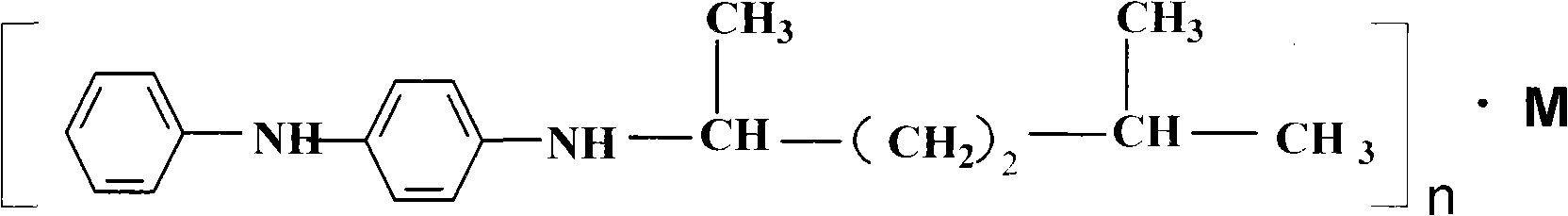

[0017] The rubber anti-aging agent of the present embodiment is an optimized rubber anti-aging agent, which is composed of N-(1,3-dimethylbutyl)-N'-phenyl-p-phenylenediamine and polymethyl terephthalate calcium zinc salt The raw materials are obtained through a complex reaction, and the weight ratio of the two is 2.5:1.

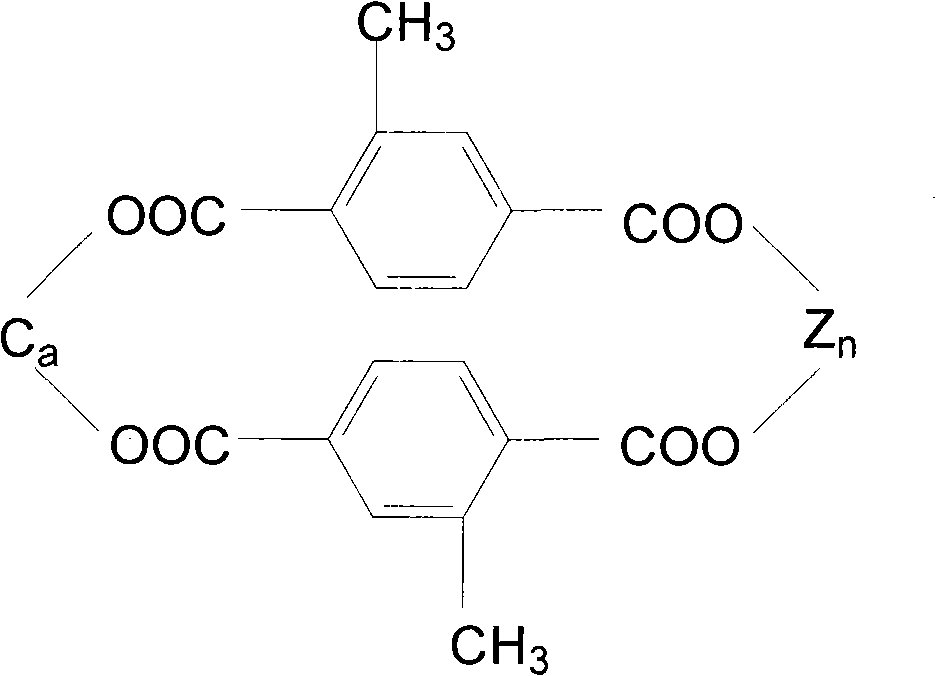

[0018] Wherein the structural formula of polymethyl terephthalate calcium zinc salt is:

[0019]

[0020] The preparation method of this optimized rubber antioxidant comprises:

[0021] ① Dissolve 250kg of N-(1,3-dimethylbutyl)-N'-phenyl-p-phenylenediamine in 250kg of acetone solution to obtain a mixed solution, then add it to the metering tank for use.

[0022] ② Add 166kg of 60wt% polymethyl terephthalate calcium zinc salt aqueous solution and 0.5kg of tetrabutylammonium chloride to a 1000L enamel reaction kettle with a cooling reflux device at the same time, and at a speed of 500r / min Stir.

[0023] ③Introduce high-temperature steam into the jacket o...

Embodiment 2

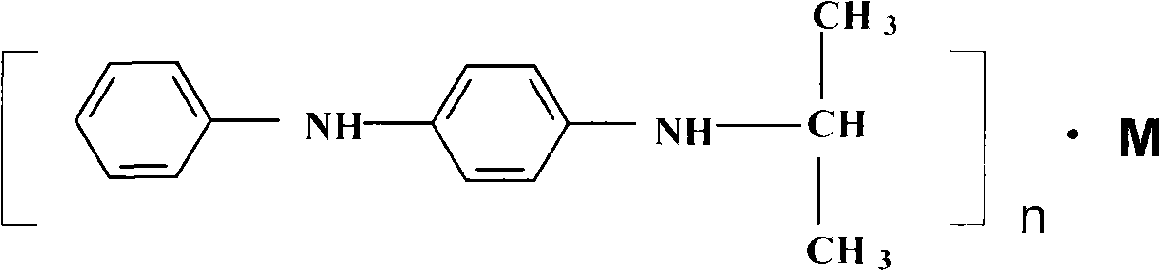

[0043] The rubber anti-aging agent of this embodiment is an optimized rubber anti-aging agent, which is obtained by complexing reaction of N-isopropyl-N'-phenyl-p-phenylenediamine and polymethyl terephthalate calcium zinc salt as raw materials. The weight ratio of those is 3:1.

[0044] The preparation method of this optimized rubber antioxidant comprises:

[0045] ① Dissolve 300kg of N-isopropyl-N'-phenyl-p-phenylenediamine in 200kg of acetone solution to obtain a mixed solution, then add it to the metering tank for use.

[0046] ② Add 160kg of 66wt% polymethyl terephthalate calcium zinc salt aqueous solution and 0.5kg of tetrabutylammonium chloride to a 1000L enamel reaction kettle with a cooling reflux device at the same time, and at a speed of 550r / min Stir.

[0047] ③Introduce high-temperature steam into the jacket of the enamel reaction kettle in step ② to heat up the material in the reaction kettle to 120°C. Add the enamel reaction kettle, and make the weight ratio o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com