Method for reducing graphene oxide and preparing conductive nanometer composite material

A composite material, conductive nanotechnology, applied in chemical instruments and methods, carbon compounds, circuits, etc., to achieve the effect of improving electrical conductivity, good electrical conductivity and thermal stability, and good industrial prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

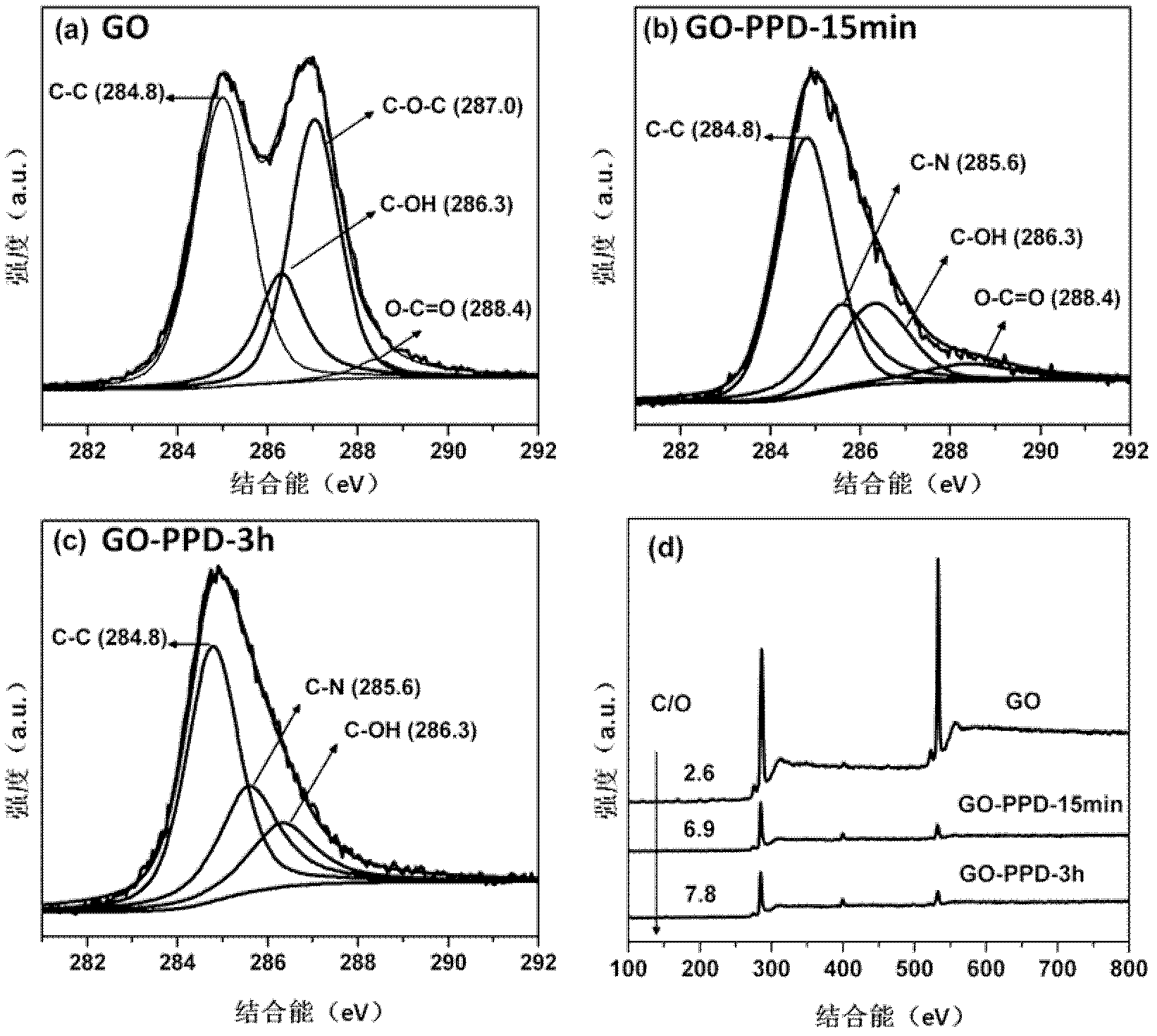

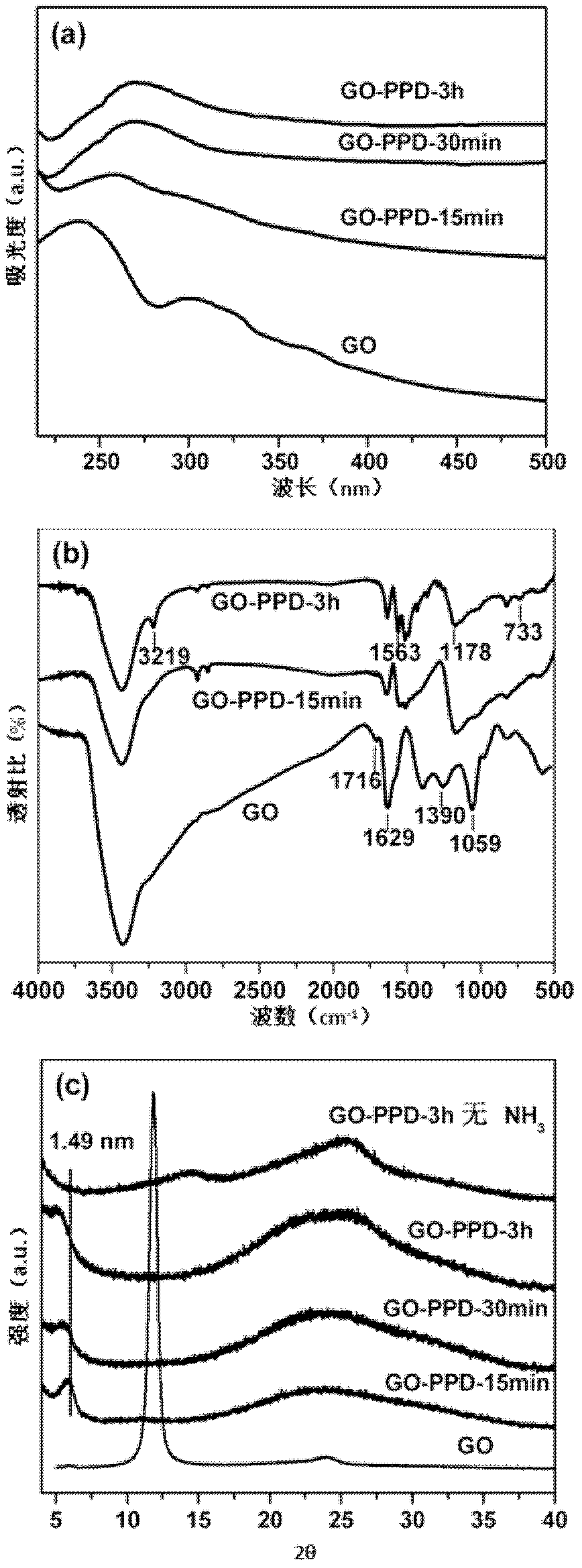

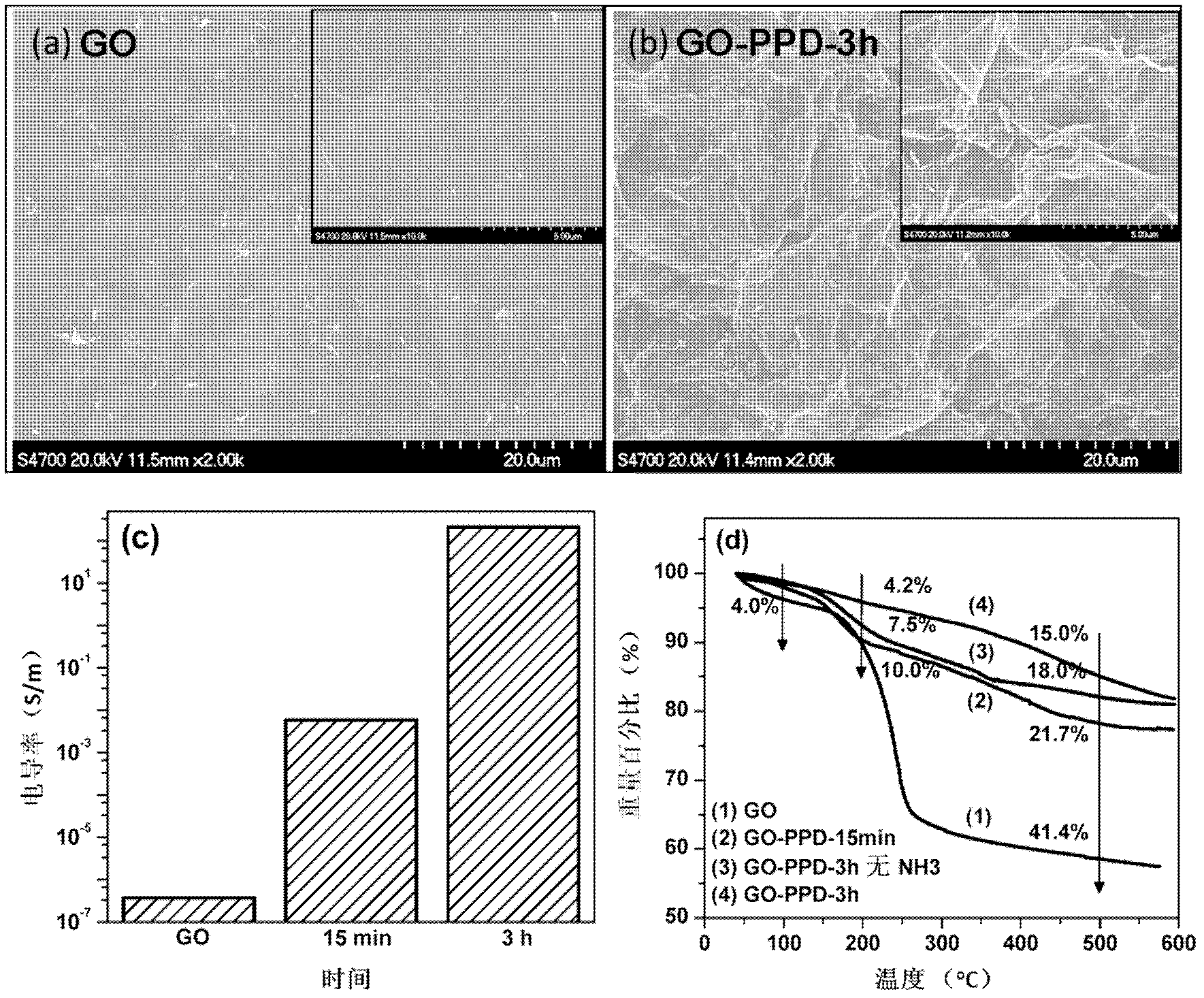

[0037] Example 1: Ultrasonic dispersion of 250 mg of GO in 500 ml of deionized water (0.5 mg / ml), ultrasonic stripping and dispersion with an ultrasonic processor at room temperature, to obtain an aqueous solution of graphene oxide; subsequently, the GO aqueous solution was transferred to a 95 ° C Heat in an oil bath while stirring mechanically, add 2.5g of PPD powder and 1500μl of NH 3 Solution, continue to react, time reflux for 15 minutes; the reaction solution is filtered with PP membrane with a pore size of 0.2 μm. The product was rinsed with ethanol, treated with ultrasonic waves for 5 minutes each time, and then filtered the ultrasonic solution several times to remove the physically adsorbed PPD; the washed product was dried in a blast oven at 80°C for 24 Hour. Labeled GO-PPD-15min. Dissolve GO-PPD-15min in 500ml of THF, break the cells for 30min, and at the same time, at 35°C, dissolve 10g of PS pellets in THF (0.1g / ml), stir mechanically, and fully dissolve to obtai...

Embodiment 2

[0038] Example 2: Consistent with the reduction method in Example 1, the reflux time was increased to 30 minutes, and the obtained reaction solution was post-treated in Example 1 to obtain GO-PPD-30 minutes. GO-PPD-30min was dissolved in THF, which was consistent with the method for preparing the composite material in Example 1, and finally a 1.15vol% PS / GO-PPD composite material sample was also prepared (the GO raw material before the reaction was used as the measurement standard).

Embodiment 3

[0039] Example 3: Consistent with the reduction method in Example 1, the reflux time was increased to 3h, and the obtained reaction solution was post-treated in Example 1 to obtain GO-PPD-3h. Dissolving GO-PPD-3h in THF was consistent with the method for preparing the composite material in Example 1, and finally a 1.15vol% PS / GO-PPD composite material sample was also prepared (the GO raw material before the reaction was used as the measurement standard).

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com