Lithium battery composite diaphragm coated with hybrid aramid fibers and preparation method of lithium battery composite diaphragm

A technology of composite diaphragm and battery diaphragm, which is applied in the direction of lithium batteries, battery pack parts, non-aqueous electrolyte batteries, etc., can solve the problems of demanding coating process and equipment, difficulties in lithium battery diaphragms, and sensitivity to moisture content, etc., to reduce Storage cost, not easy to precipitate, and the effect of improving tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

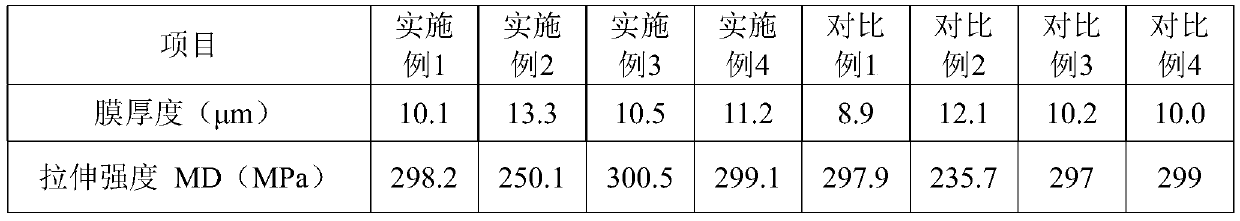

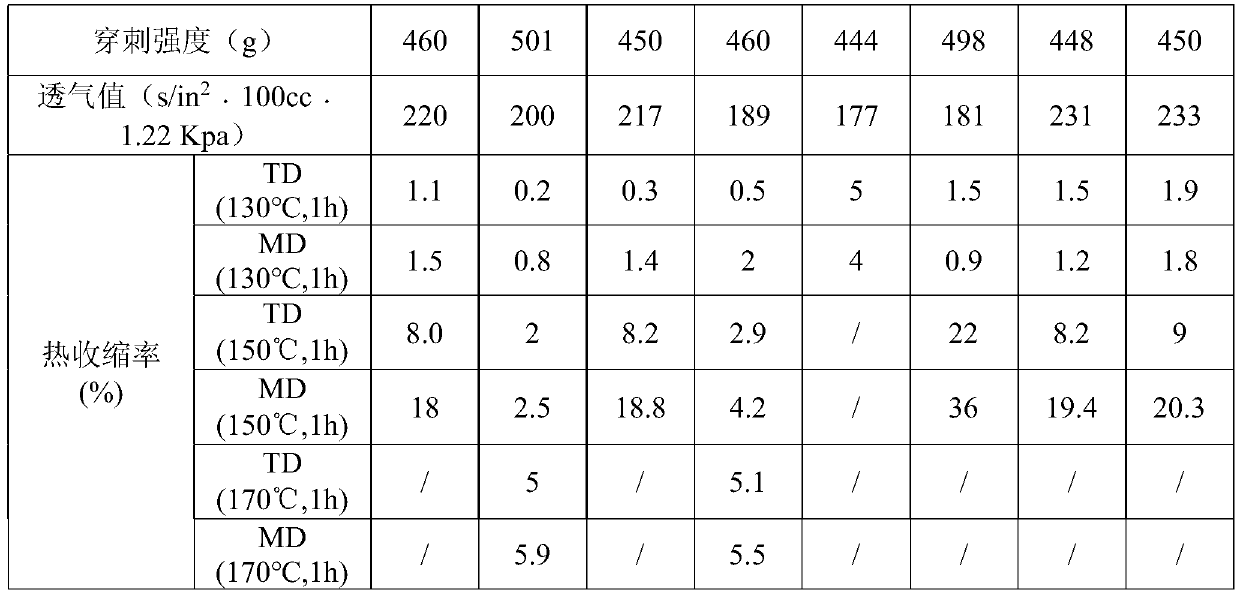

Examples

Embodiment 1

[0030] (1) At room temperature, in the reactor, add 25L dimethylacetamide / calcium chloride solvent, feed nitrogen, and stir, add p-phenylenediamine (PPD), until completely dissolved, at this time, the reactor body The temperature will gradually rise to about 40°C, stir and continue to cool down, so that the temperature in the kettle body drops to about 10°C, add isophthaloyl chloride (IPC), react for 20 minutes, add calcium hydroxide, and make the pH value of the synthesis solution reach Neutral, after 4 minutes, the prepared slurry containing poly-p-phenylene isophthalamide (1314 aramid fiber) is poured into a closed plastic bucket;

[0031] (2) Select a polyethylene battery separator with a thickness of 9 μm, send the battery separator to the coating device, use the slurry prepared in step (1) to coat, and apply dip coating to both sides of the battery separator;

[0032] (3) immersing the battery diaphragm coated in step (2) in a plasticizing bath, where the plasticizing ba...

Embodiment 2

[0035] The difference between this example and Example 1 is that a ceramic separator with a 9 μm polyethylene base film + 3 μm inorganic ceramic particle coating is selected as the battery separator, and the same slurry as in Example 1 is used for coating.

Embodiment 3

[0037] The difference between this embodiment and Example 1 is: using m-phenylenediamine (MPD) and terephthaloyl chloride (TPC) as reaction monomers to prepare poly-m-phenylenediamine terephthalamide (1413 aromatic Lun) slurry; use this slurry to coat battery separators.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com