Novel process for preparing p-phenylene diisocyanate (PPDI) based on phosgene

A p-phenylene diisocyanate, a new process technology, applied in the field of preparation of chemical raw materials, can solve the problems of slow reaction process, environmental pollution, complex production process, etc., to achieve the effect of reducing pollutant emissions and avoiding slow reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

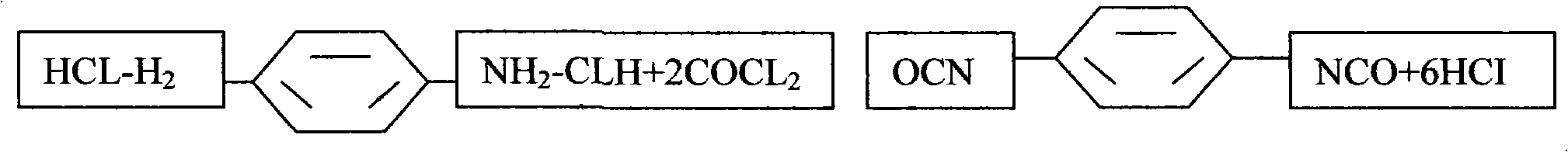

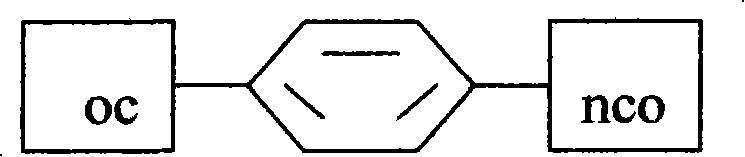

[0016] This specific embodiment adopts the following technical process steps: 1, hydrochloric acid generating reaction; 2, salt-forming reaction; 3, photochemical reaction;

[0017] Described hydrochloric acid generation reaction is will quantitative POCl 3 Vacuum into the metering tank, put a certain amount of hydrochloric acid in the hydrochloric acid generator, and slowly add POCl dropwise 3 The reaction generates HCl, and the reaction formula is as follows: POCl 3 +3H 2 O→H 3 PO 4 +3HCl;

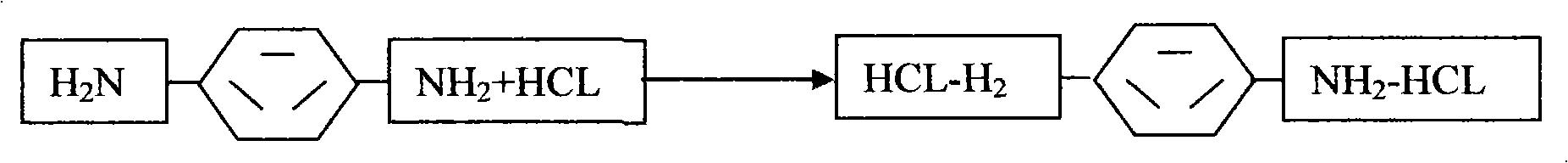

[0018] The salt-forming reaction is to put a certain amount of solvent o-dichlorobenzene into a salt-forming reaction kettle, add a certain amount of p-phenylenediamine to heat in a full reflux state, dissolve p-phenylenediamine, pass a certain amount of HCl, and take a sample to test the pH. When the pH value is between 3 and 4, the salt formation is over, and the tail gas is removed and broken. The reaction formula is as follows:

[0019]

[0020] In the photochemical reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com