Nitrogen and phosphorus containing flame retardant agent and preparation method thereof as well as application thereof

A flame retardant, nitrogen and phosphorus technology, applied in the field of flame retardant, can solve problems such as poor resistance to dripping, and achieve the effects of being beneficial to environmental protection, improving physical and mechanical properties, and improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

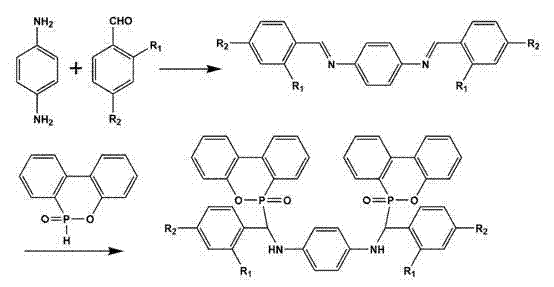

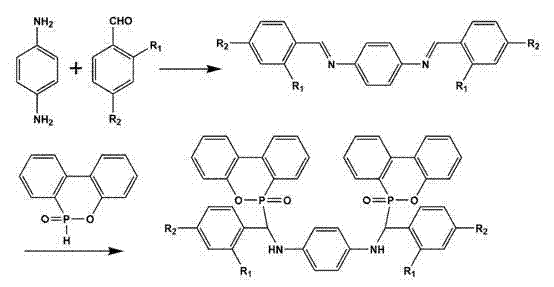

Method used

Image

Examples

Embodiment 1

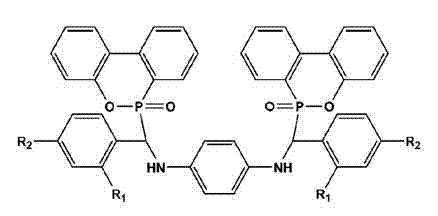

[0033] N , N' -di[(10'-oxo-10'-hydrogen-9'-oxa-10' lambda 5 -Phosphaphenanthrene-10'-yl)-phenyl-methyl]-phenyl-1,4-diamine synthesis, the steps are as follows:

[0034] Add 10.8g of p-phenylenediamine, 21.2g of benzaldehyde, and 128g of ethanol into a three-necked flask equipped with a stirrer and a reflux condenser, stir, control the reaction temperature at 80°C, cool after 2 hours of reaction, and then filter the reaction mixture , washed, and dried in an oven at 80°C for 6 hours to obtain an imine intermediate product; the stirring speed in this condensation reaction is 50-400 rpm.

[0035]Add 28.4g of the yellow solid obtained above, 43.2g of DOPO, and 286.4g of ethanol into a three-necked flask equipped with a stirrer and a reflux condenser, stir and control the reaction temperature at 80°C, react for 4 hours and then cool, and then the product Filter, wash, and dry in an oven at 100°C for 8 hours to obtain a nitrogen-phosphorus-containing flame retardant solid; in th...

Embodiment 2

[0045] Synthesis of 4,4'-{1'',4''-phenylene-bis[amino-(10'''-oxo-10'''-hydrogen-9'''-oxa-10''' lambda 5 -phosphaphenanthrene-10'''-yl)-methyl]}-diphenol, the steps are as follows:

[0046] Add 10.8g of p-phenylenediamine, 24.4g of p-hydroxybenzaldehyde, and 352g of ethanol into a three-necked flask equipped with a stirrer and a reflux condenser, stir, control the reaction temperature at 0°C, and cool after reacting for 5 hours, then react The mixture was filtered, washed, and dried in an oven at 80° C. for 6 hours to obtain an imine intermediate.

[0047] Add 31.6g of imine, 43.2g of DOPO, and 748g of ethanol obtained above into a three-necked flask equipped with a stirrer and a reflux condenser, stir and control the reaction temperature at 50°C, react for 10 hours, cool down, and then filter the product , washed, and dried in an oven at 60° C. for 8 hours to obtain a solid flame retardant containing nitrogen and phosphorus.

[0048] The resulting product was tested by infr...

Embodiment 3

[0056] Synthesis of 2,2'-{1'',4''-phenylene-bis[amino-(10'''-oxo-10'''-hydrogen-9'''-oxa-10''' lambda 5 -phosphaphenanthrene-10'''-yl)-methyl]}-diphenol, the steps are as follows:

[0057] Add 10.8g of p-phenylenediamine, 24.4g of salicylaldehyde, and 704g of ethanol into a three-necked flask equipped with a stirrer and a reflux condenser, stir, control the reaction temperature at 40°C, and cool the reaction mixture after 10 hours. Filter, wash, and dry in an oven at 80° C. for 6 hours to obtain an imine intermediate product.

[0058] Add 31.6g of imine, 43.2g of DOPO, and 1496g of ethanol obtained above into a three-necked flask equipped with a stirrer and a reflux condenser, stir and control the reaction temperature at 0°C, react for 24 hours, cool down, and then filter the product , washed, and dried in an oven at 80° C. for 8 hours to obtain a solid nitrogen-phosphorus-containing flame retardant.

[0059] The resulting product was tested by infrared spectroscopy, NMR, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com