Automotive abrasion-resistant damping rubber and preparation method thereof

A technology of shock-absorbing rubber and automobiles, applied in the field of rubber materials, to achieve the effects of good wear resistance, good elasticity, and improved elasticity and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

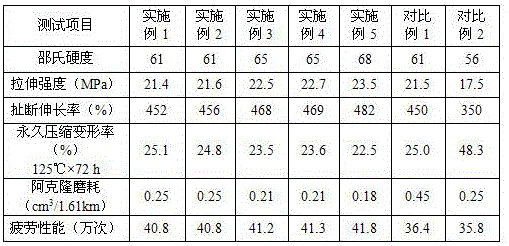

Examples

Embodiment 1

[0017] A wear-resistant and shock-absorbing rubber for automobiles, which is prepared from the following components in parts by weight: 65 parts of natural rubber, 35 parts of butadiene rubber, 30 parts of high wear-resistant carbon black N330, 7 parts of zinc oxide, and 1.8 parts of stearic acid 2.5 parts of sulfur, 2 parts of N-isopropyl-N'-phenyl-p-phenylenediamine, 1.5 parts of styrenated phenol, 1 part of dibenzothiazole disulfide, 2 parts of tetramethylthiuram disulfide 10 parts of polyether polyurethane modified epoxy resin, 3 parts of polyacrylate toughened modified epoxy resin, 2 parts of nano-silicon carbide, 2 parts of calcium sulfate whiskers, and 5 parts of magnesium borate whiskers.

[0018] The preparation method of the above-mentioned wear-resistant and shock-absorbing rubber for automobiles is as follows: (1) adding natural rubber and butadiene rubber into the mixer, and mixing for 5 minutes at a temperature of 60 ° C and a pressure of 2 MPa; Add the rubber ma...

Embodiment 2

[0020] A wear-resistant and shock-absorbing rubber for automobiles, which is prepared from the following components in parts by weight: 55 parts of natural rubber, 40 parts of butadiene rubber, 20 parts of high wear-resistant carbon black N330, 4 parts of zinc oxide, and 1.2 parts of stearic acid 5.5 parts of sulfur, 1.5 parts of N-isopropyl-N'-phenyl-p-phenylenediamine, 2 parts of styrenated phenol, 2 parts of dibenzothiazole disulfide, 1 part of tetramethylthiuram disulfide , 3 parts of polyether polyurethane modified epoxy resin, 10 parts of polyacrylate toughened modified epoxy resin, 5 parts of nano-silicon carbide, 5 parts of calcium sulfate whiskers, and 2 parts of magnesium borate whiskers.

[0021] The preparation method of the above-mentioned wear-resistant and shock-absorbing rubber for automobiles is as follows: (1) adding natural rubber and butadiene rubber into the mixer, and mixing for 10 minutes at a temperature of 50 ° C and a pressure of 2 MPa; (2) mixing Add...

Embodiment 3

[0023] A wear-resistant and shock-absorbing rubber for automobiles, which is prepared from the following components in parts by weight: 58 parts of natural rubber, 38 parts of butadiene rubber, 28 parts of high wear-resistant carbon black N330, 5 parts of zinc oxide, and 1.4 parts of stearic acid 4.5 parts of sulfur, 1.6 parts of N-isopropyl-N'-phenyl-p-phenylenediamine, 1.8 parts of styrenated phenol, 1.2 parts of dibenzothiazole disulfide, 1.8 parts of tetramethylthiuram disulfide , 5 parts of polyether type polyurethane modified epoxy resin, 8 parts of polyacrylate toughened modified epoxy resin, 4 parts of nano-silicon carbide, 3 parts of calcium sulfate whiskers, and 4 parts of magnesium borate whiskers.

[0024] The preparation method of the above-mentioned wear-resistant and shock-absorbing rubber for automobiles is as follows: (1) adding natural rubber and butadiene rubber into the mixer, and mixing for 8 minutes at a temperature of 55 ° C and a pressure of 2 MPa; Add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Acron wear | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com