Preparation method for preparation of phenylenediamine through dinitrobenzene continuous catalytic hydrogenation

A technology of dinitrobenzene and catalytic hydrogenation, applied in the preparation of organic compounds, chemical instruments and methods, preparation of amino compounds, etc., can solve the problems of pollution, low catalyst recovery efficiency, etc., to reduce pollution and reduce the impact on human body. Harm, waste reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

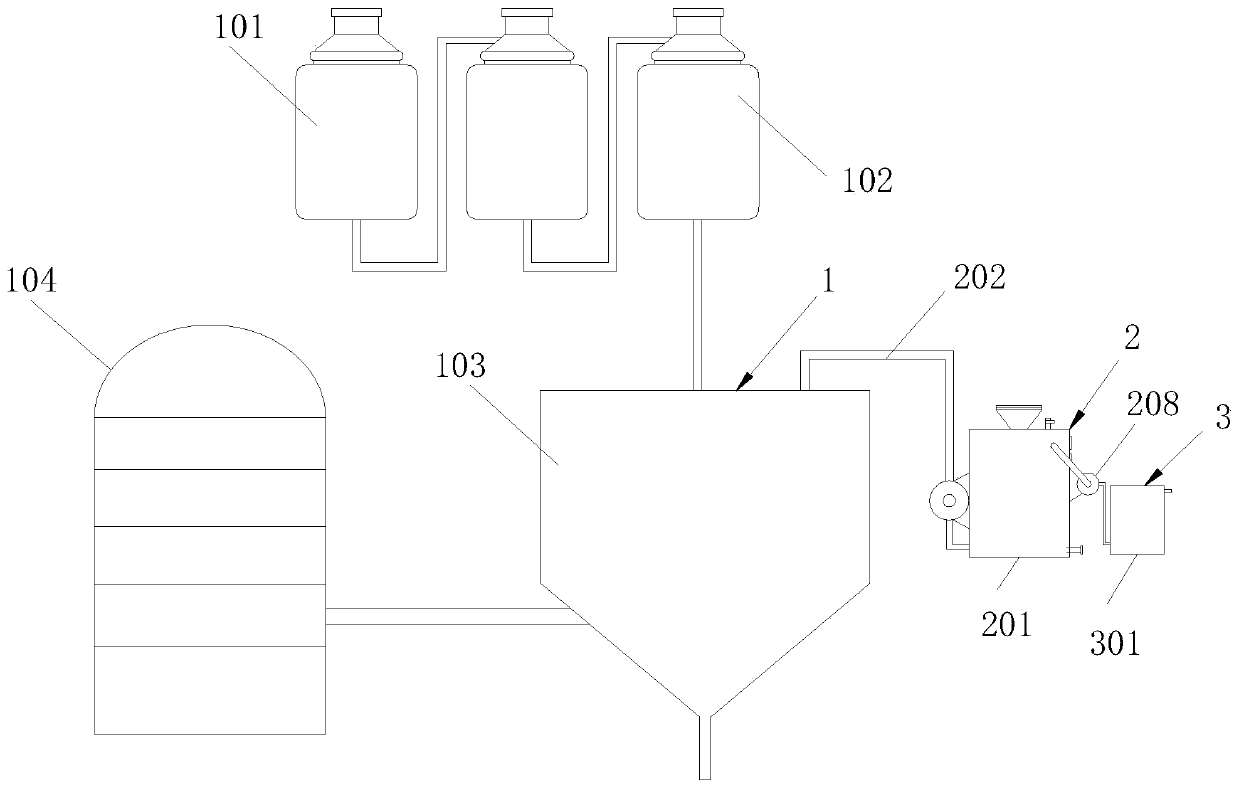

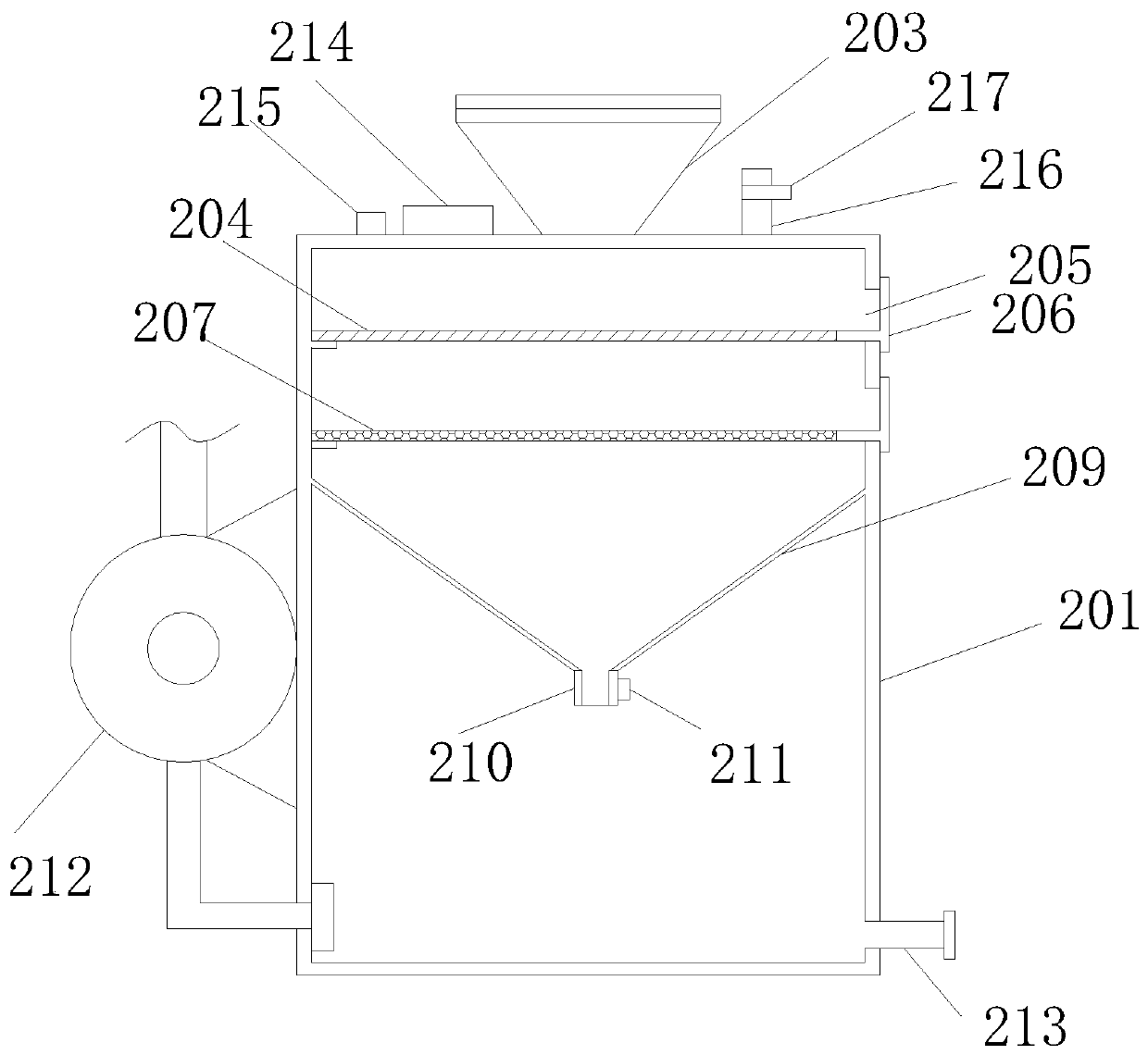

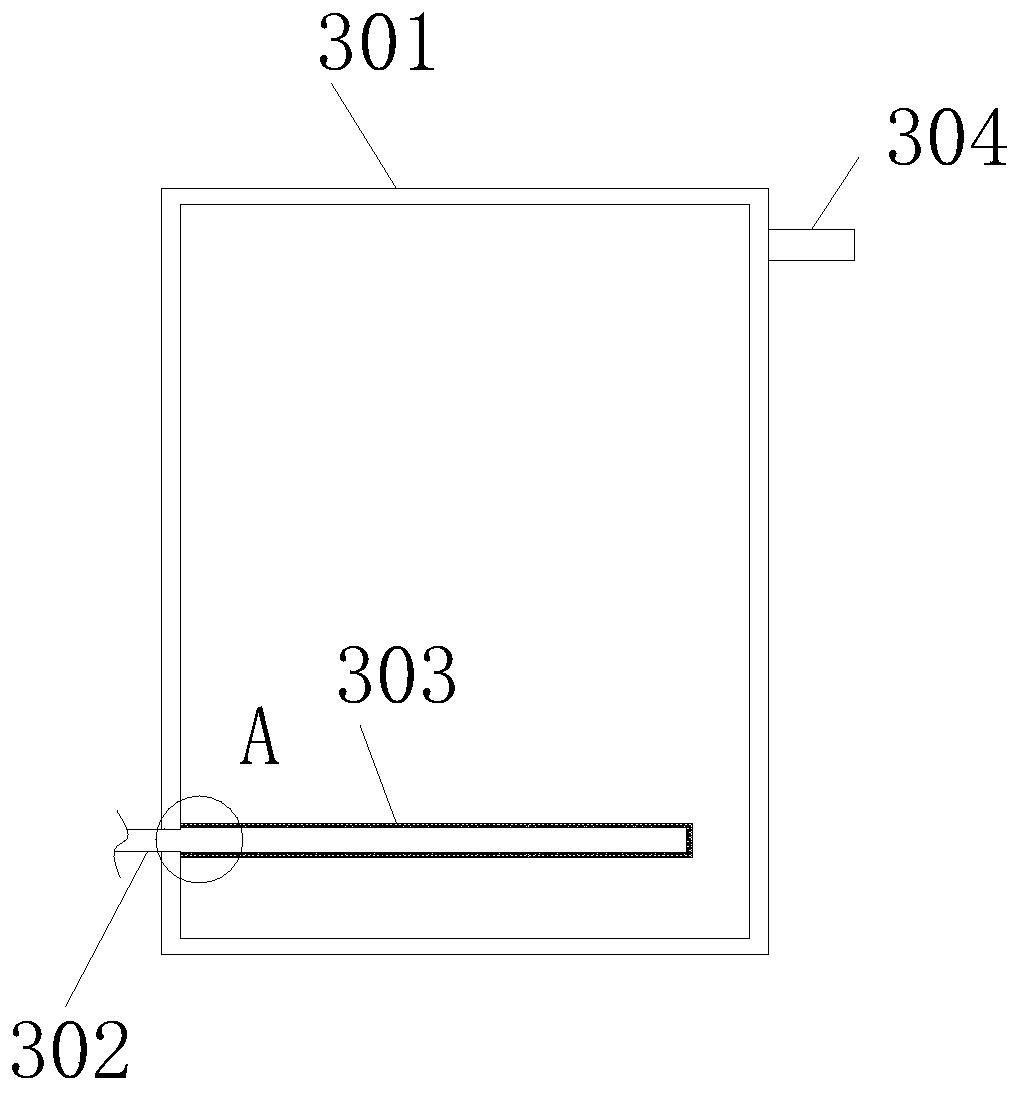

[0025] see Figure 1-4 , the present invention provides a technical solution: a preparation method for continuous catalytic hydrogenation of dinitrobenzene for the preparation of phenylenediamine, which uses a phenylenediamine preparation device to realize the preparation of phenylenediamine, characterized in that: phenylenediamine The amine preparation device includes a preparation component 1 , a recovery component 2 and a purification component 3 .

[0026] The preparation component 1 includes: a hydrogenation reactor 101, a maturation reactor 102, a multi-stage settling tank 103 and a recti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com