Preparation method of catalyst used for synthesizing phenylenediamine rubber anti-aging agent

A rubber anti-aging agent and catalyst technology, applied in the field of precious metal catalyst preparation, can solve the problems of strict production operation requirements, unstable catalyst performance, catalyst poisoning, etc., achieve firm adsorption, avoid unstable catalyst performance, and facilitate selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

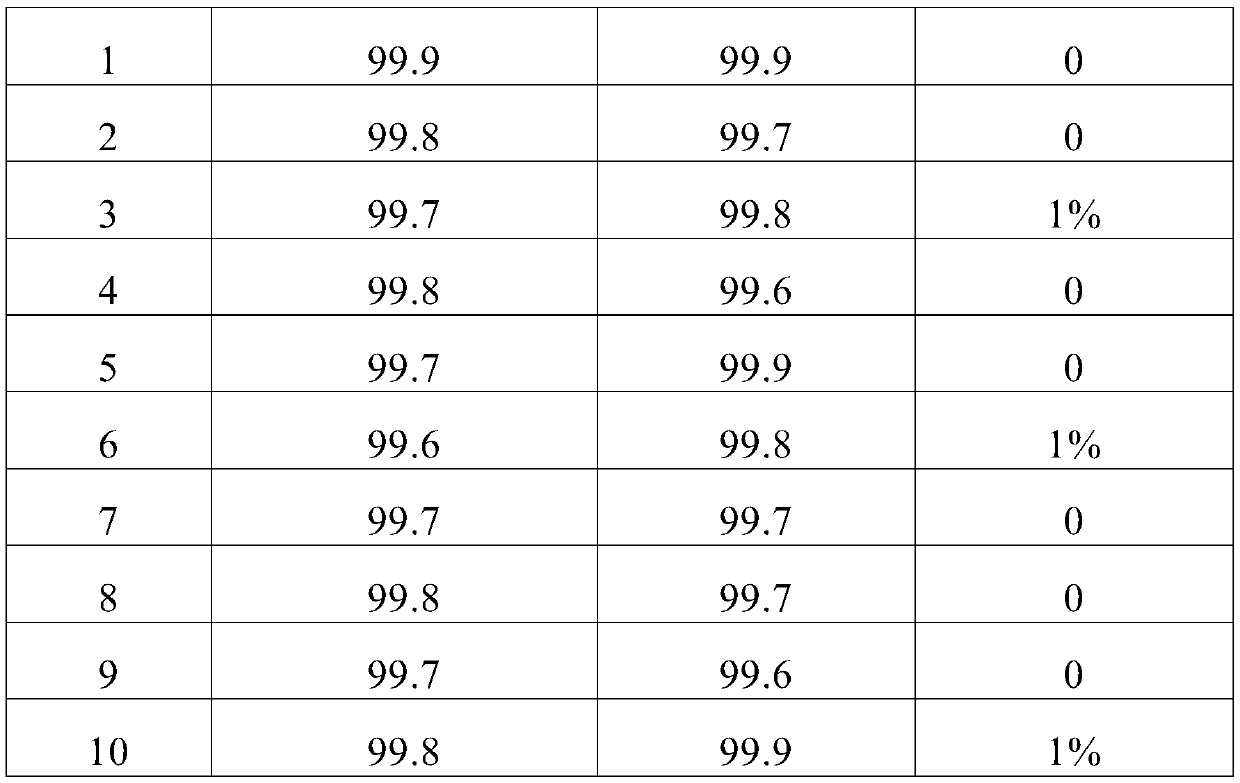

Examples

Embodiment 1

[0025] The catalyst for the synthesis of phenylenediamine rubber anti-aging agent of the present embodiment includes an activated carbon carrier, platinum, iron and nickel loaded on the activated carbon carrier, the mass percentage of platinum in the catalyst is 2%, and the mass percentage of iron 0.1%, the mass percentage of nickel is 0.5%;

[0026] The preparation method of present embodiment catalyst comprises the following steps:

[0027] Step 1. The particle size is 200-400 mesh and the specific surface area is 1000m 2 The gac / g is placed in boiling mass percent concentration in 5% hydrochloric acid aqueous solution for reflux treatment for 1h, then washed to neutral with deionized water, and then dried to obtain gac carrier;

[0028] Step 2, 0.048g FeCl 3 ·6H 2 O, 0.202g NiCl 2 ·6H 2 O and 0.006g PVP (polyvinylpyrrolidone) were dissolved in 50mL deionized water to obtain solution A, and then dehydrated alcohol equal to the volume of solution A was added to solution ...

Embodiment 2

[0033] The catalyst for the synthesis of phenylenediamine rubber anti-aging agent of the present embodiment includes an activated carbon carrier, platinum, iron and nickel loaded on the activated carbon carrier, the mass percentage of platinum in the catalyst is 3%, and the mass percentage of iron is 1%, and the mass percentage of nickel is 1.75%;

[0034] The preparation method of present embodiment catalyst comprises the following steps:

[0035] Step 1. The particle size is 200-400 mesh and the specific surface area is 1200m 2 The gac / g is placed in boiling mass percent concentration in 5% hydrochloric acid aqueous solution for reflux treatment for 1h, then washed to neutral with deionized water, and then dried to obtain gac carrier;

[0036] Step 2, 0.723g Fe(NO 3 ) 3 9H 2 O, 0.867g Ni(NO 3 ) 2 ·6H2 0 and 0.034g CTAB (cetyltrimethylammonium bromide) were dissolved in 50mL deionized water to obtain solution A, and then the dehydrated alcohol equal to the volume of sol...

Embodiment 3

[0041] The catalyst for the synthesis of phenylenediamine rubber anti-aging agent of the present embodiment includes an activated carbon carrier, platinum, iron and nickel loaded on the activated carbon carrier, the mass percentage of platinum in the catalyst is 5%, and the mass percentage of iron is 2%, and the mass percentage of nickel is 3%;

[0042] The preparation method of present embodiment catalyst comprises the following steps:

[0043] Step 1. The particle size is 200-400 mesh and the specific surface area is 1500m 2 The gac / g is placed in boiling mass percent concentration in 15% hydrochloric acid aqueous solution for reflux treatment for 3h, then washed to neutral with deionized water, and then dried to obtain gac carrier;

[0044] Step 2, 0.968g FeCl 3 ·6H 2 O, 1.486g Ni(NO 3 ) 2 ·6H 2 0 and 0.083g SDBS (sodium dodecylbenzenesulfonate) were dissolved in 50mL deionized water to obtain solution A, and then the dehydrated alcohol equal to the volume of solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com