Method for producing polyimide laminate, and polyimide laminate

A technology for polyimide layers and laminates, applied in the field of polyimide laminates and their preparation, can solve the problems of reduced adhesion, reduced system vacuum, insufficient heat resistance, etc., and achieves inhibition of thermal decomposition. , Excellent heat resistance, high heat resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0125] In a 500 mL (internal volume) glass reactor equipped with a stirrer and a nitrogen inlet / outlet tube, 410.1267 g of N-methyl-2-pyrrolidone was placed as a solvent. Then, 26.8886 g (0.2486 moles) of PPD and 73.1431 g (0.2486 moles) of s-BPDA were added thereto, and the mixture was stirred at 50° C. to provide polyamic acid having 18.21% solid content and 0.65 dL / g intrinsic viscosity Solution. Then, 2.0006g (0.0061 mol, 2.5 mol% based on 100 mol% of the tetracarboxylic acid component, 2.0wt% based on the total weight of the tetracarboxylic acid component and diamine component, the same applies below) Triphenyl ester is added as a phosphorus compound to the obtained polyamic acid solution.

[0126] The polyamic acid solution was applied on a glass plate as a substrate with a bar coater. The resulting coating film was heated at 120°C for 10 minutes, 150°C for 40 minutes, 180°C for 60 minutes, 200°C for 10 minutes, 250°C for 10 minutes, and then 500°C for 5 minutes to be on ...

Embodiment 2

[0129] The same procedure as in Example 1 was implemented, except that 5.016 g (0.0153 mol, 6.2 mol %, 5.0 wt %) of triphenyl phosphate was added as the phosphorus compound. The results are shown in Table 2.

Embodiment 3

[0131] The same procedure as in Example 1 was performed, except that 15.0160 g (0.0460 mol, 18.5 mol %, 15.0 wt %) of triphenyl phosphate was added as the phosphorus compound. The results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

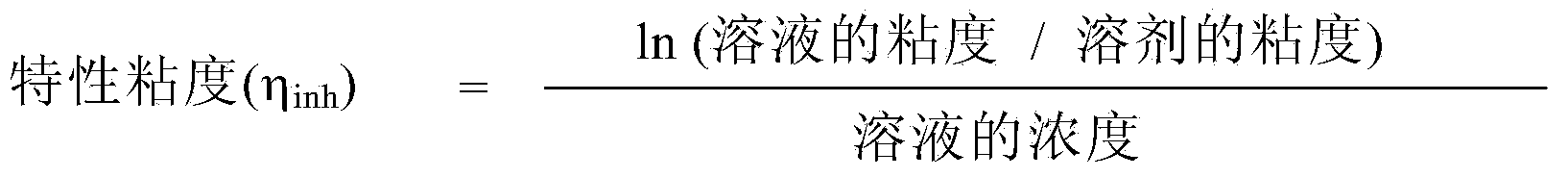

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com