High-performance silicone/fluoroether composite rubber glove and preparation method thereof

A technology of fluoroether rubber and composite rubber, which is applied in the field of high-performance silicone/fluoroether composite rubber gloves and its preparation, to achieve excellent oil resistance, excellent high and low temperature resistance, processability, and increased dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

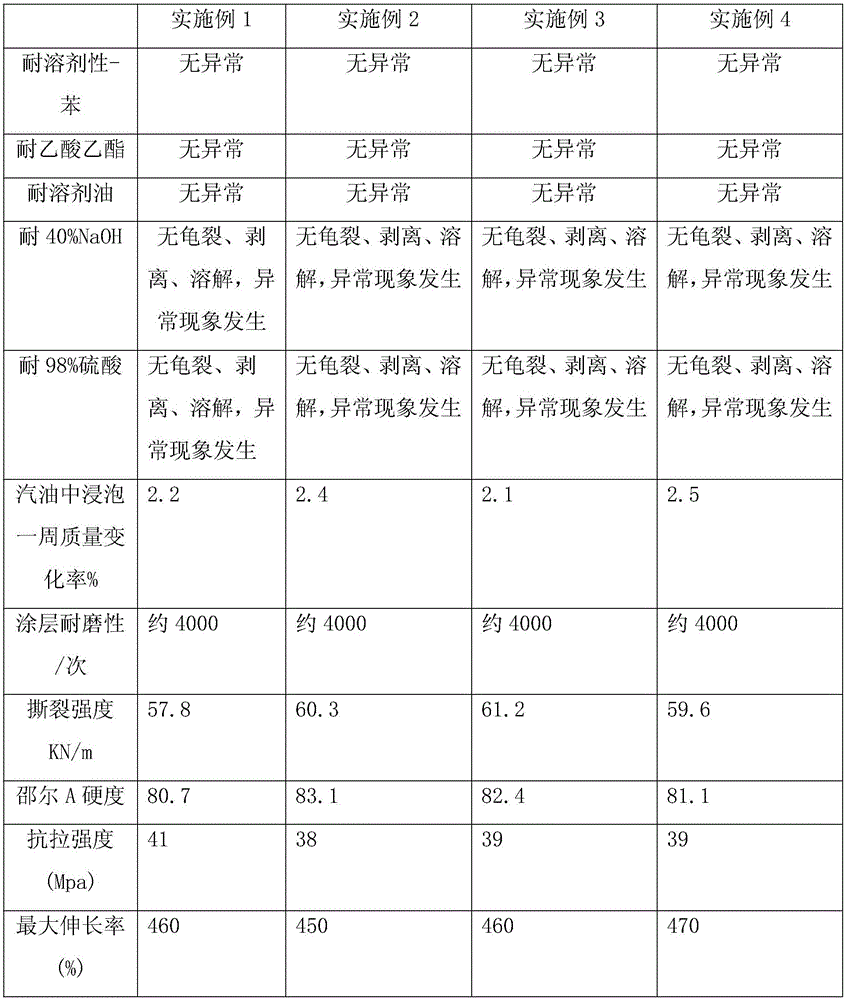

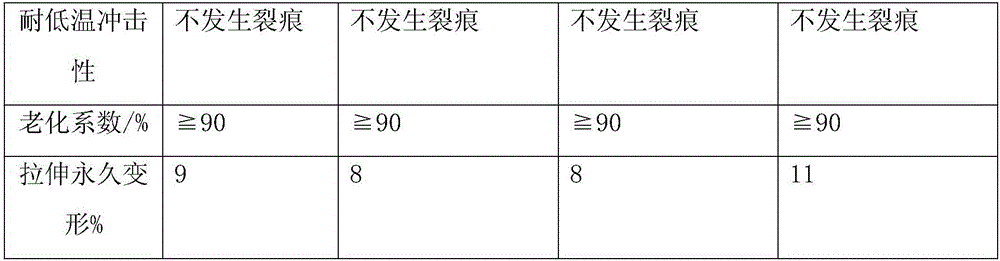

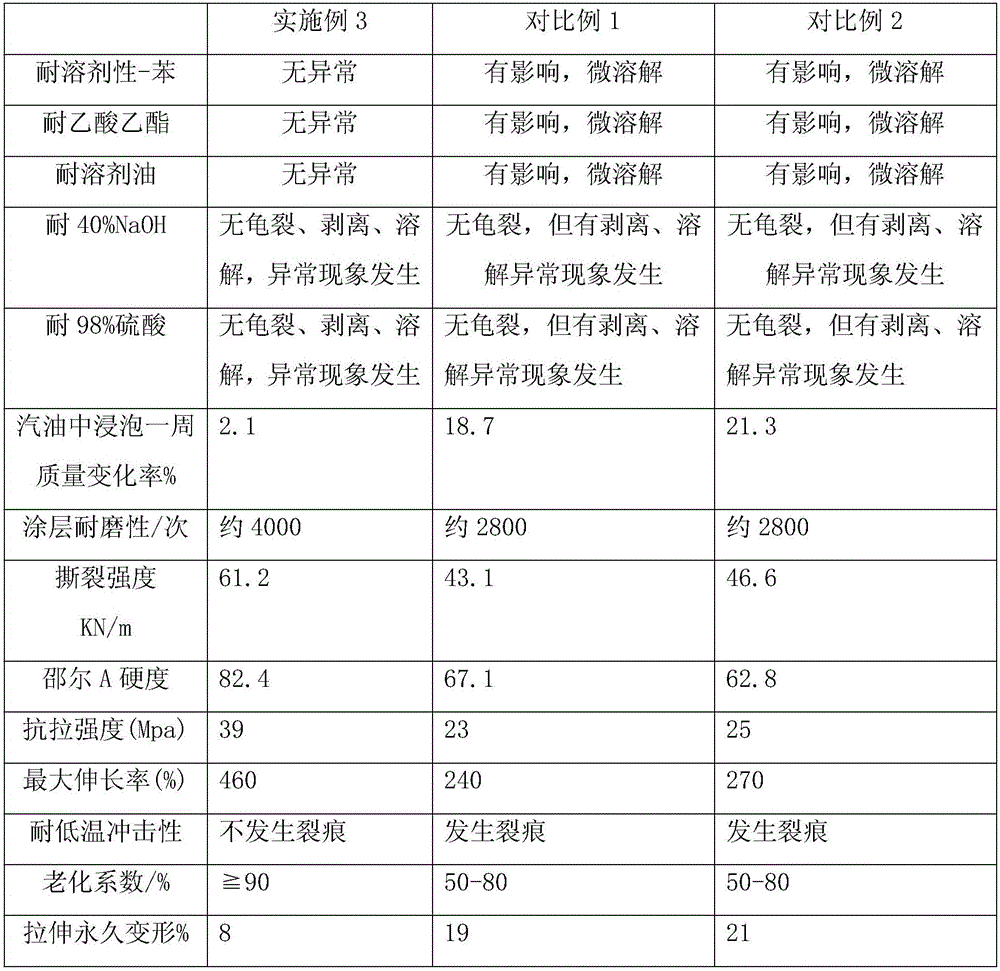

Embodiment 1

[0026] A high-performance silicone / fluoroether composite rubber glove, comprising a fiber glove liner, coated with a silicon / fluoroether rubber layer on the surface of the fiber glove liner, the silicon / fluoroether rubber layer is impregnated with silicon / fluoroether rubber glue The method of slurry is coated on the surface of the fiber glove lining; wherein the silicon / fluoroether composite rubber is made of the following components in parts by weight: 80 parts of fluoroether rubber, 40 parts of methyl vinyl silicone rubber, and 1 part of oxidation vulcanizing agent DCP, 5 parts of zinc oxide, 15 parts of phenolic resin, 0.5 part of accelerator, 0.1 part of antioxidant 1010, 15 parts of hydroxyethyl methacrylate modified graphene, 3 parts of dioctyl phthalate, 0.8 parts of B-naphthyl-p-phenylenediamine, 50 parts of tetrahydrofuran; wherein, the accelerator is a mixture of accelerator ZBX and accelerator ZDEC in a weight ratio of 1:1.

Embodiment 2

[0028] A high-performance silicone / fluoroether composite rubber glove, comprising a fiber glove liner, coated with a silicon / fluoroether rubber layer on the surface of the fiber glove liner, the silicon / fluoroether rubber layer is impregnated with silicon / fluoroether rubber glue The way of slurry is coated on the surface of the fiber glove lining; wherein the silicon / fluoroether composite rubber is made of the following components in parts by weight: 120 parts of fluoroether rubber, 60 parts of methyl vinyl silicone rubber, and 3 parts of oxidation curing agent DCP, 8 parts of zinc oxide, 30 parts of phenolic resin, 1.5 parts of accelerator, 0.5 part of antioxidant 1010, 30 parts of graphene modified by hydroxyethyl methacrylate, 6 parts of dioctyl phthalate, 1.6 parts of B-naphthyl-p-phenylenediamine, 100 parts of tetrahydrofuran; wherein, the accelerator is a mixture of accelerator ZBX and accelerator ZDEC in a weight ratio of 1:1.

Embodiment 3

[0030] A high-performance silicone / fluoroether composite rubber glove, comprising a fiber glove liner, coated with a silicon / fluoroether rubber layer on the surface of the fiber glove liner, the silicon / fluoroether rubber layer is impregnated with silicon / fluoroether rubber glue The way of slurry is coated on the surface of the fiber glove lining; wherein the silicon / fluoroether composite rubber is made of the following components in parts by weight: 100 parts of fluoroether rubber, 50 parts of methyl vinyl silicone rubber, and 2 parts of oxidation vulcanizing agent DCP, 6 parts of zinc oxide, 24 parts of phenolic resin, 1 part of accelerator, 0.3 part of antioxidant DSTP, 22 parts of hydroxyethyl methacrylate modified graphene, 4 parts of dioctyl phthalate, 1.2 parts of B-naphthyl-p-phenylenediamine, 75 parts of tetrahydrofuran; wherein, the accelerator is a mixture of accelerator ZBX and accelerator ZDEC in a weight ratio of 1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com