Rubber composition of automobile motor suspension

A technology for a rubber composition and an automobile engine, applied in the field of rubber, can solve the problems of rubber creep, adverse effects of strong metal bonding properties, poor shock absorption effect and driving safety, waste of rubber and metal materials, etc. Improve creep and dynamic fatigue, long protection period, excellent dynamic fatigue effect

Active Publication Date: 2018-01-05

SHANGHAI ZHONGLI INVESTMENT

View PDF6 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the stiffness is low and the hardness of the rubber is relatively low, which has an adverse effect on rubber creep, strength, and bonding properties with metals

At the same time, due to the low stiffness, the displacement becomes larger under dynamic use conditions, and the rubber at the stress concentration point is broken; in addition, the aging resistance of natural rubber is not good, the modulus loss is large during use, and the rubber creep is serious

In light cases, a new set of mounts needs to be replaced, resulting in a waste of rubber and metal material resources, and in serious cases, it will cause the engine to shift and affect the service life of the powertrain

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0022] A kind of automobile engine suspension rubber composition, contains following component by weight part:

[0023] Table 1

[0024]

Embodiment 2

[0026] A kind of automobile engine suspension rubber composition, contains following component by weight part:

[0027] Table 2

[0028]

[0029]

Embodiment 3

[0031] A kind of automobile engine suspension rubber composition, contains following component by weight part:

[0032] table 3

[0033]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

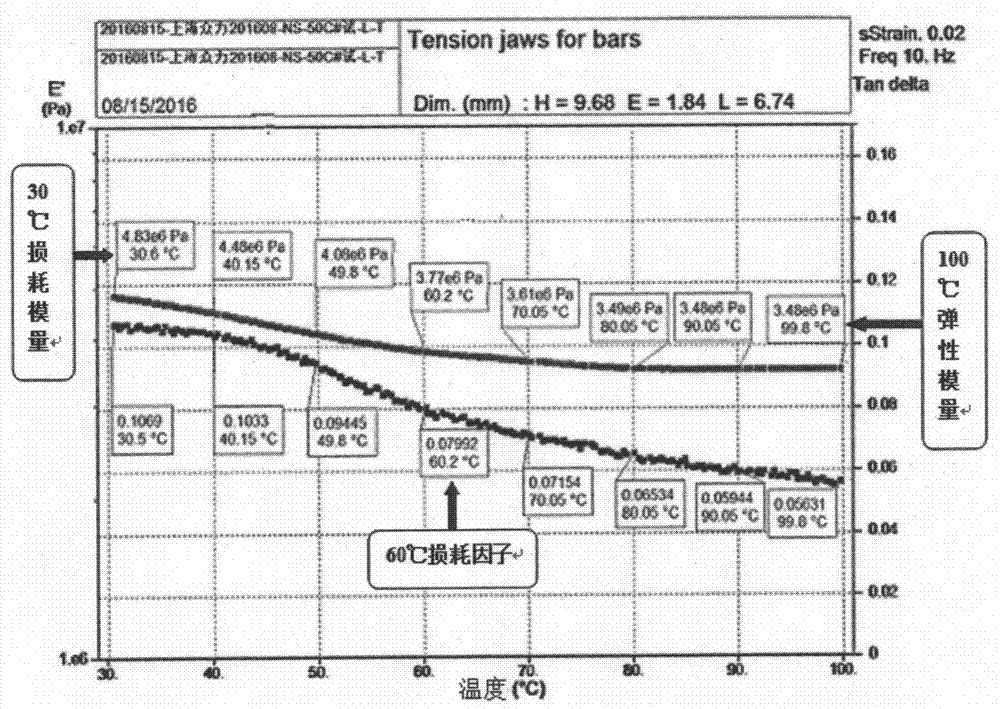

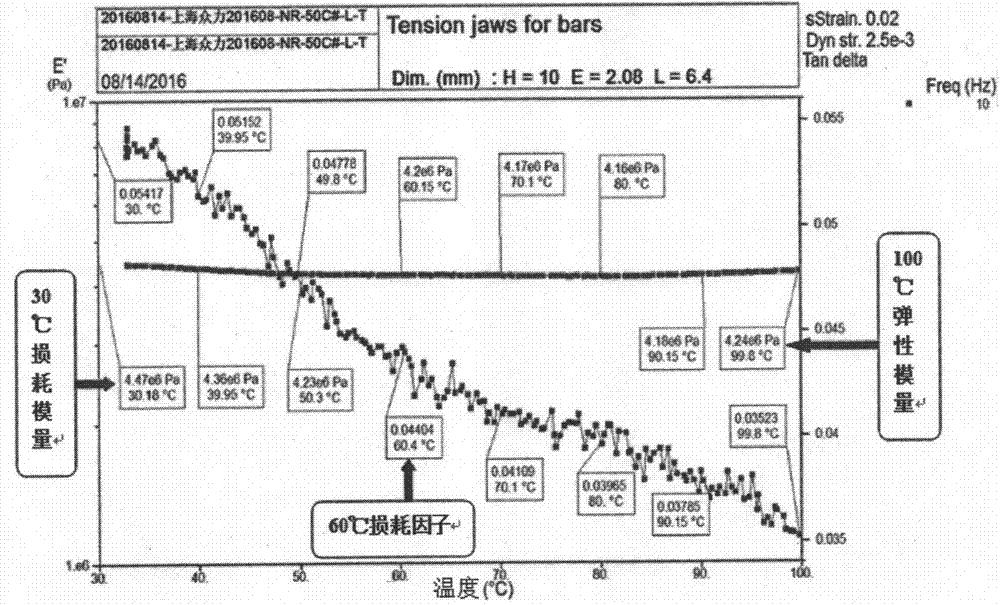

The invention discloses a rubber composition of automobile motor suspension. The composition is prepared from, by weight, 2.5-3.5 parts of physical antiager, 7-10 parts of activating agent, 5-8 partsof plasticizer, 0.6-1 part of vulcanizing agent, 100 parts of white carbon black wet natural rubber, 1.5-2.5 parts of diaryl secondary amine antiager, 2-3 parts of para-phenylenediamine derivative antiager, 18-25 parts of reinforcing agent, 1.5-2 parts of assistant crosslinker and 1.5-1.8 parts of accelerator. The rubber composition of the automobile motor suspension has the advantages that the high temperature resistance and heat resistance performance is good, and dynamic modulus loss is low; physical property change of a rubber material is little after aging, the strength retaining rate ishigh, and permanent deformation through high-temperature compression is good; the produced motor suspension has low stiffness and good NVH effect, high-temperature creep and high-temperature fatigue performance, and the motor suspension is at the top of the industry and recognized by clients at home and abroad.

Description

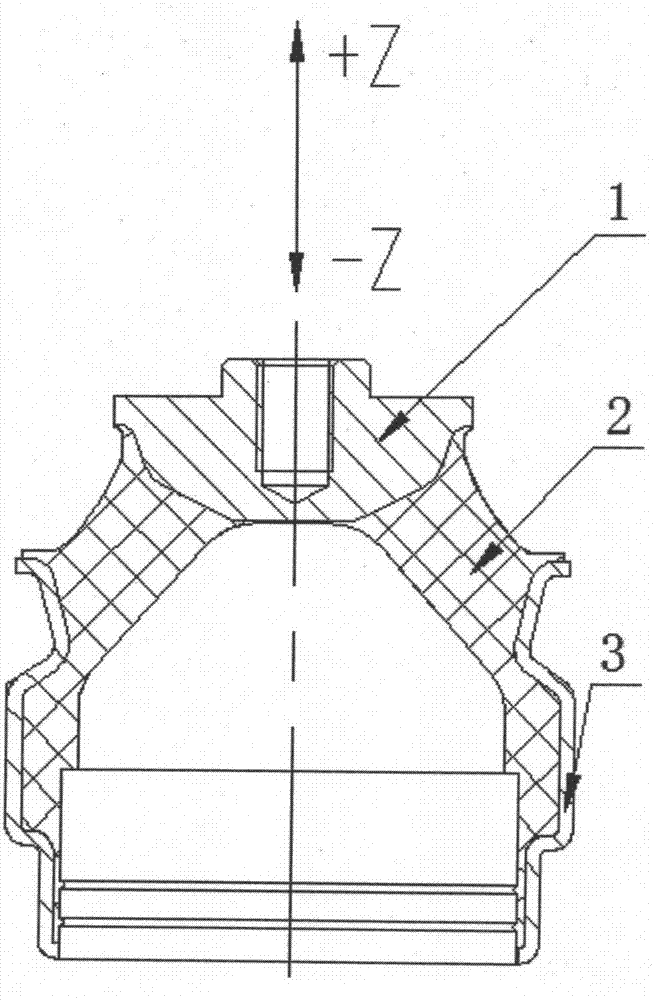

technical field [0001] The invention relates to a rubber composition for automobile engine suspension, which is used for making automobile engine suspension main springs and suspension components, and belongs to the technical field of rubber. Background technique [0002] The main function of the automobile engine mount is to support the mass of the engine assembly, and to avoid excessive displacement of the power assembly and interference with other components under loads such as starting, shifting, acceleration, braking, steering, and impact on uneven roads . As an important part connecting the powertrain and the body, the suspension system not only supports and stabilizes the engine, but also isolates the vibration generated by the engine from being transmitted to the frame and cab, reducing vibration and noise. Therefore, the suspension plays a very important role in the NVH performance of the vehicle, and it needs to have good vibration isolation performance. Because ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L7/00C08L91/00C08K13/02C08K3/36C08K5/18C08K3/22C08K5/09C08K3/04

Inventor 田中龙

Owner SHANGHAI ZHONGLI INVESTMENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com