Patents

Literature

32results about How to "Small creep at high temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for making low-creepage and high-strength high temperature resisting ceramic roller

InactiveCN102249710ASmall creep at high temperatureImprove high temperature performanceMulliteMineral particles

The invention relates to a method for making a low-creepage and high-strength high temperature resisting ceramic roller. A mullite whisker in-situ reinforcement technology and a crystal boundary glass phase crystallization technology are adopted, a mineralizer containing zirconium and titanium is added to enable andalusite mineral particles in a blank to generate uniformly distributed mullite whiskers in-situ in the high-temperature reaction of kaolin with alpha-Al2O3, and thermal treatment is carried out in the cooling process to crystallize a crystal boundary liquid phase. Compared with thetraditional same type of high temperature resisting ceramic roller, the finally prepared low-creepage and high-strength high temperature resisting ceramic roller has the advantages that the high temperature strength below 1350DEG C is improved by 15-20%, and the high-temperature creepage under the condition of 1350DEG C*50hr is reduced by more than 35%.

Owner:JINGDEZHEN NUONAI TECH CERAMICS

Preparation method of low-zirconium mullite cast steel brick

The invention relates to a preparation method of a low-zirconium mullite cast steel brick, and belongs to the field of preparation of refractory materials. The raw material formula of the low-zirconium mullite cast steel brick provided by the invention comprises electrically smelted mullite, zirconium oxide, Guangxi white clay, andalusite, kyanite and lignin. According to the method provided by the invention, type and grain size of the raw materials are selected to be matched with the sintering temperature and time provided by the invention, so that the prepared low-zirconium mullite cast steel brick has the characteristics of excellent scouring resistance, high temperature resistance, small creep deformation, high compression strength, good thermal stability and the like, and is suitable for being used in large steel ingot casting in nuclear power products.

Owner:四川锦圆耐材有限公司

Composite high temperature electrical heating element and its making method

InactiveCN1838841AImprove bindingNot easy to peel offHeating element shapesHeating element materialsSolid reactionGraphite

The invention relates to a composite high-temperature electric heating element and relative producing method, which is formed by graphite, carbon silicon and molybdenum silicide. Wherein, the graphite is used as basis layer, which is coated with carbon silicon layer to be coated with molybdenum silicide layer. The invention uses the high-temperature solid reaction disperse method to composite three materials, to realize the continuous gradient change from inner to outer. The invention has lower cost, less high-temperature creep, high high-temperature strengthen, and the application for high-temperature oxide area.

Owner:GUIYANG AL-MG DESIGN & RES INST

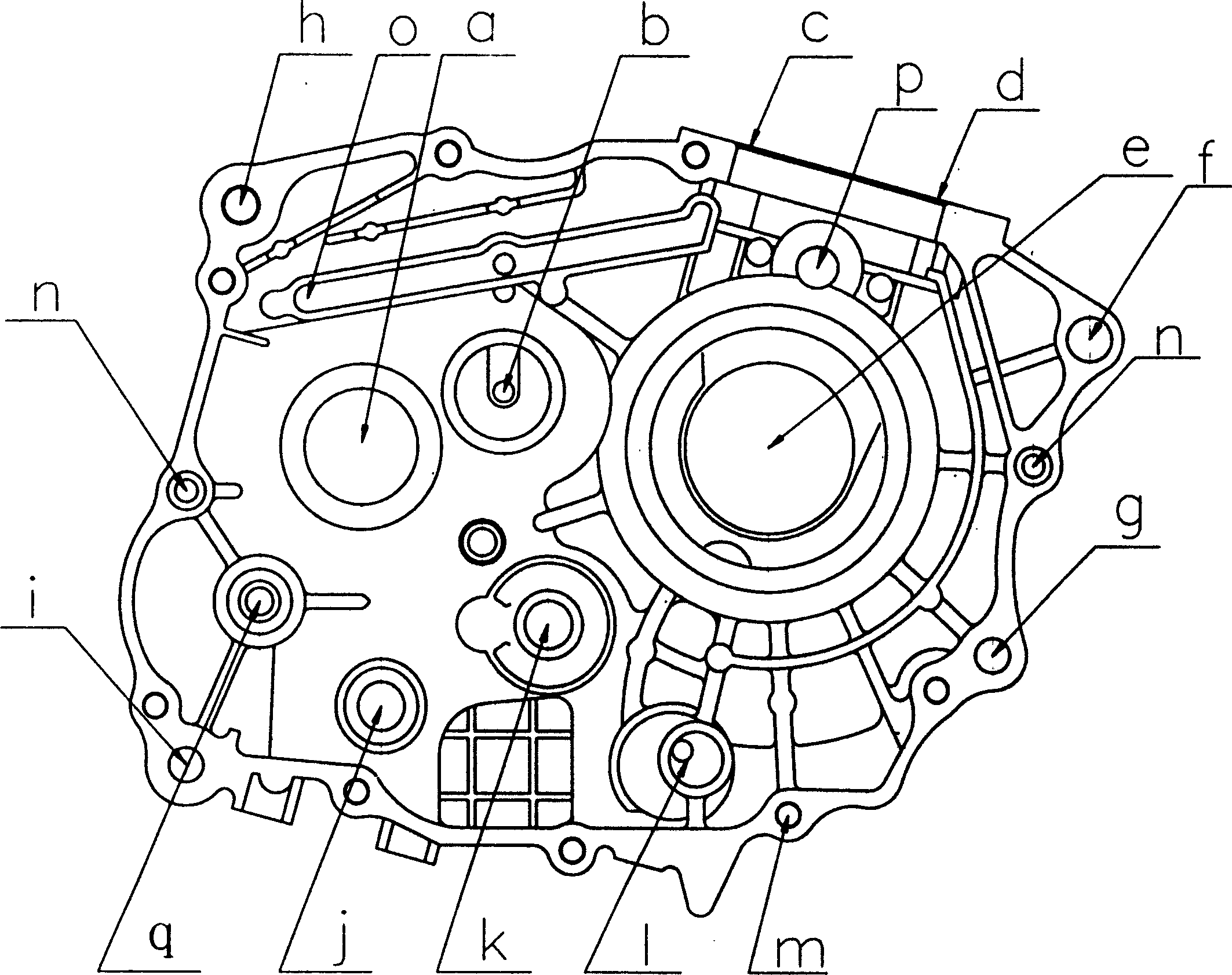

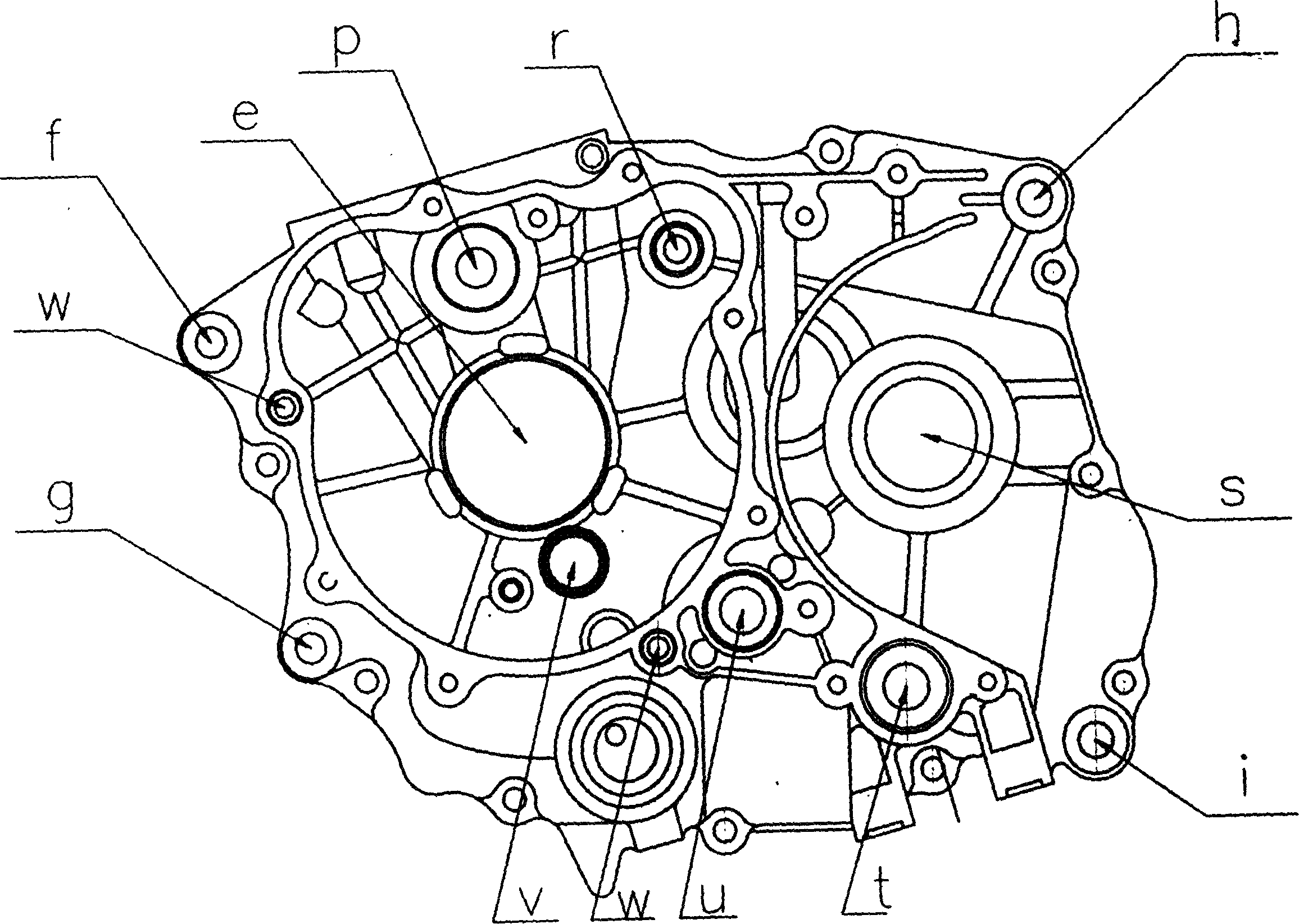

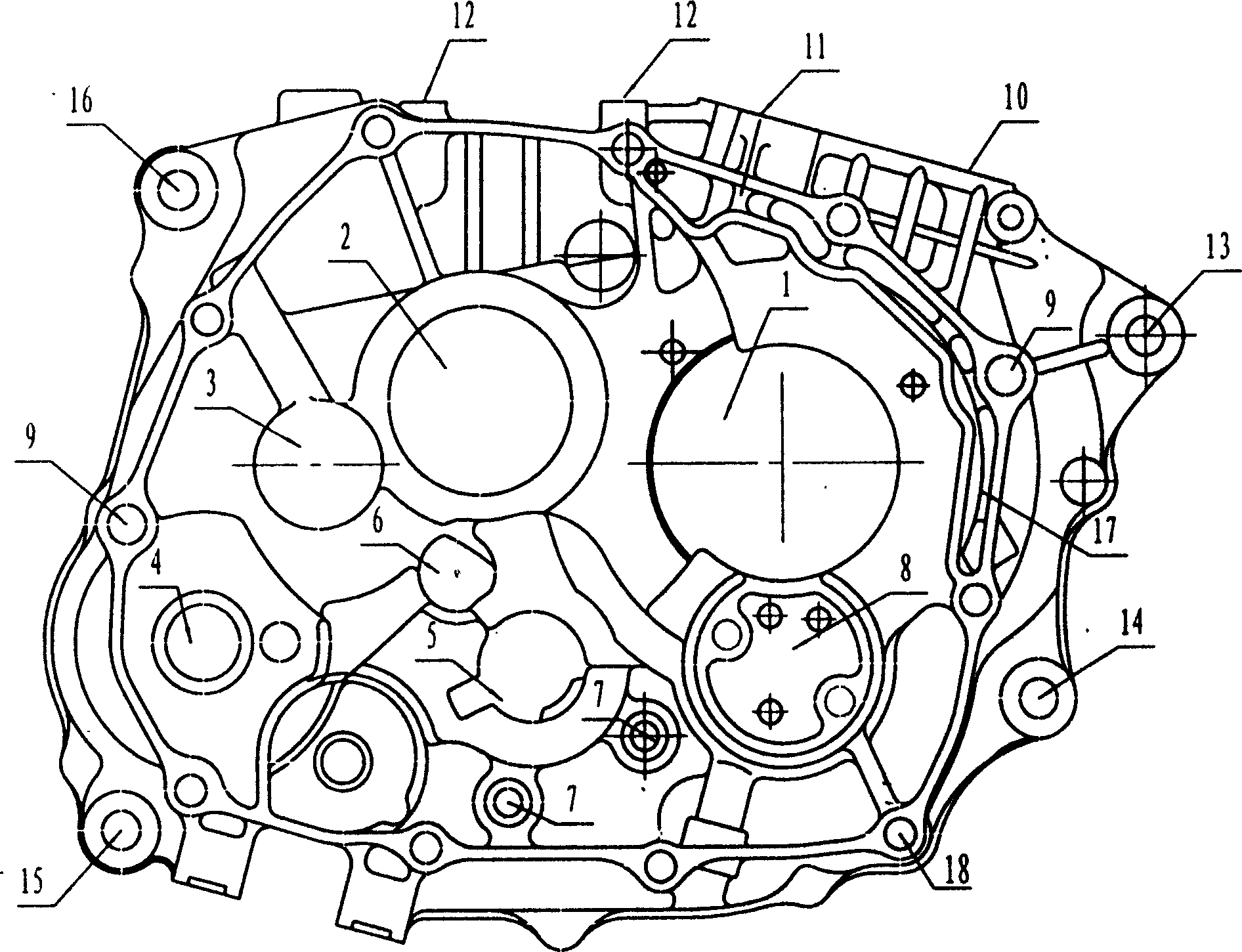

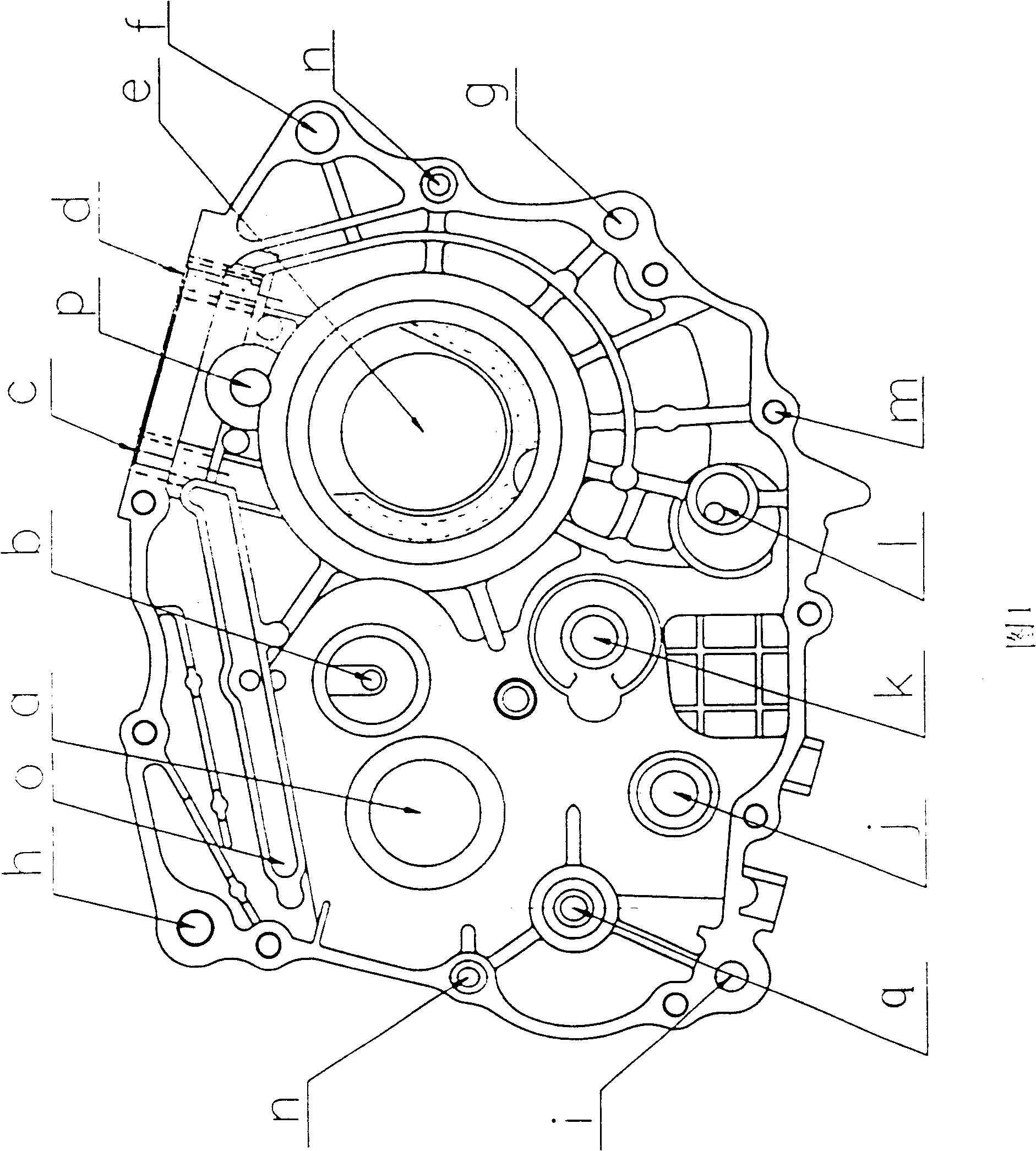

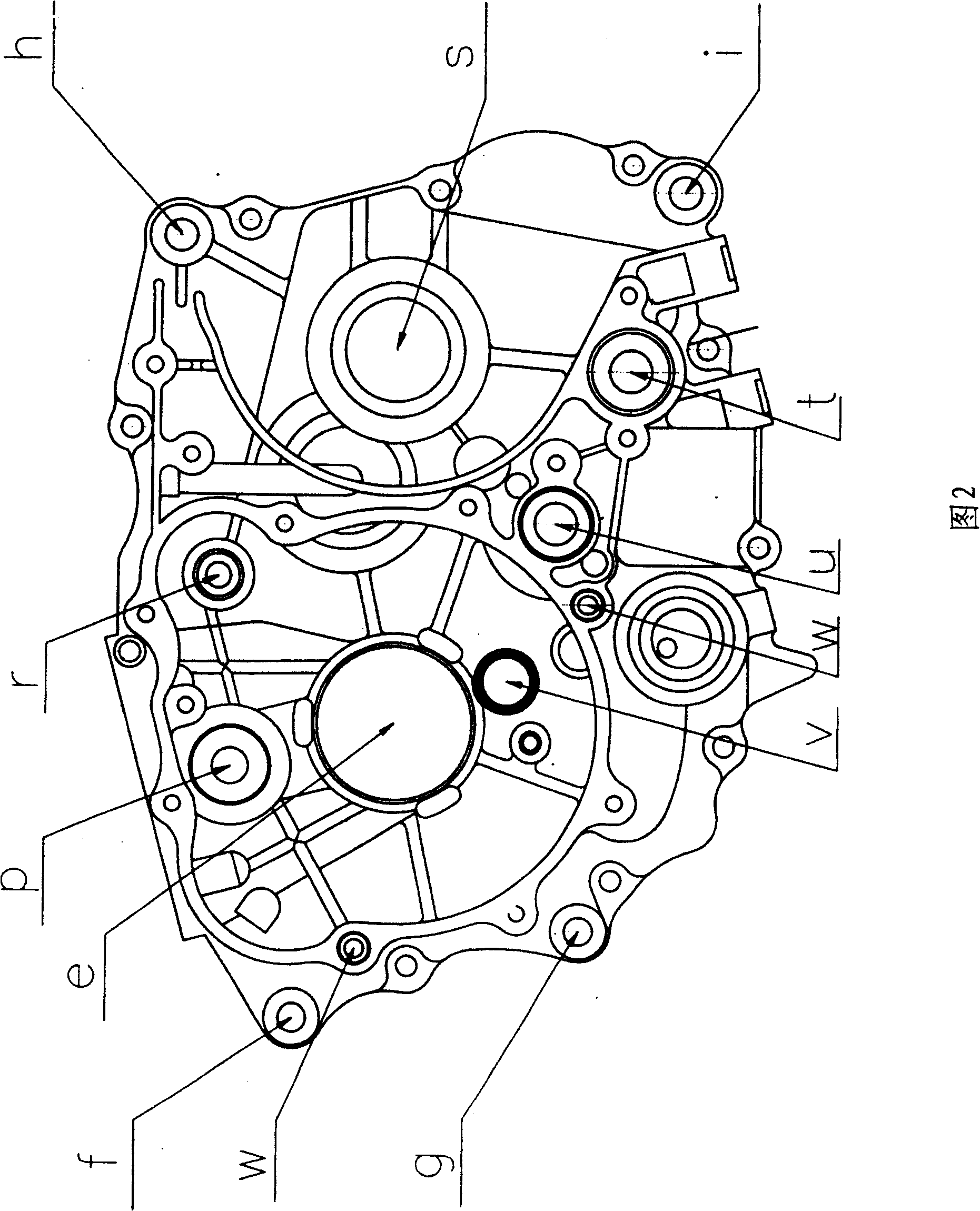

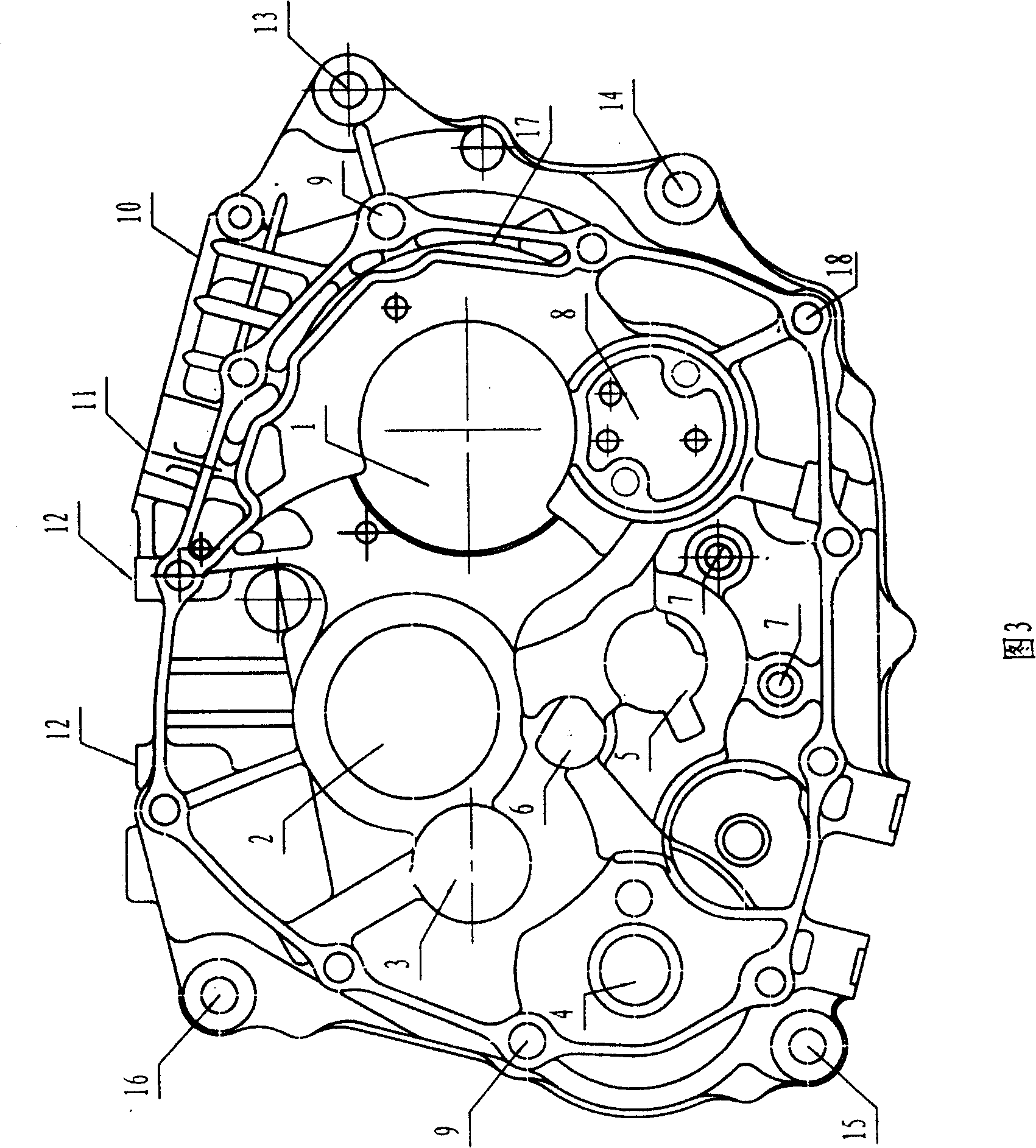

Reducing vibration type engine crankcase of motorcycle

InactiveCN1560460AImprove structural strengthIncrease cooling areaCasingsMachines/enginesCrankcaseEngineering

The invention belongs to combustion engine crank box, which is a crank box for the vibration damping motorcycle engine, made up of left crank box and the right crank box, the character lies in: the left and the right crank boxes use magnesium alloy to be cast and formed, the thickness of the box wall is 3.5-6mm, several reinforcing ribs with width of 3-5mm are arranged on the box surface and the cover. Compared to the gearing aluminum alloy crank box, when the structure intensity of the box is upgraded, the heat irradiating area is also increased, it can reduce the high temperature creep, the mechanical intensity of the magnesium alloy crank box in the high temperature environment is not affected; the experience to the same motorcycle LC125 testifies, the crank box of the invention caters all the demands of engine, and the weight is reduced, thus it can save 0.4l oil per hundred kilometers, the average heat vibration and noise only the 1 / 3 of the traditional crank box.

Owner:重庆镁业科技股份有限公司

Low-zirconium mullite draft tube brick and preparation method thereof

The invention relates to a low-zirconium mullite draft tube brick and a preparation method thereof, belonging to the field of refractory materials. The low-zirconium mullite draft tube brick comprises the following raw materials by weight: 45 to 55 parts of fused mullite, 15 to 25 parts of zirconia, 3 to 8 parts of Guangxi white mud, 15 to 25 parts of andalusite, 2 to 5 parts of kyanite and 1 to 5 parts of lignin. According to the invention, through selection of types and particle sizes of the raw materials and cooperative usage of sintering temperature and time provided by the invention, the prepared draft tube brick has the characteristics of excellent anti-scouring performance and high temperature resistance, small creep deformation, good thermal stability, etc. and is applicable to vacuum casting of large steel ingots in a nuclear power product.

Owner:四川锦圆耐材有限公司

Production method of fused alumina/titanium oxide composite material

The invention relates to a production method of a refractory material and a thermal spraying material, in particular to a production method of a fused alumina / titanium oxide composite material. According to the production method of the fused alumina / titanium oxide composite material, high-purity Al2O3 and high-purity TiO2 serves as molten materials for high-temperature electric arc melting, an electrode is controlled not to make contact with a melting surface, the distance between the electrode and the melting surface is larger than 0 cm and smaller than or equal to 2 cm, and a low-carbon black crystal frit is formed through natural cooling after high-temperature electric arc melting and crushed into grain-size sand. Electric arcs are used for long-arc operation, the electrode is preventedfrom making contact with oxidized powder, and introduction of carbon is avoided; produced alumina is high in purity, low in porosity, high in volume density, high in high-temperature strength and abrasion resistance and good in corrosion resistance and high-temperature volume stability, can be widely applied in the thermal spraying industry, is beneficial to obtaining better thermal spraying equipment and accessories, and prolongs the service life of the equipment and the accessories.

Owner:SHANDONG LEIBAO ZIRCONIUM SCI&TECH

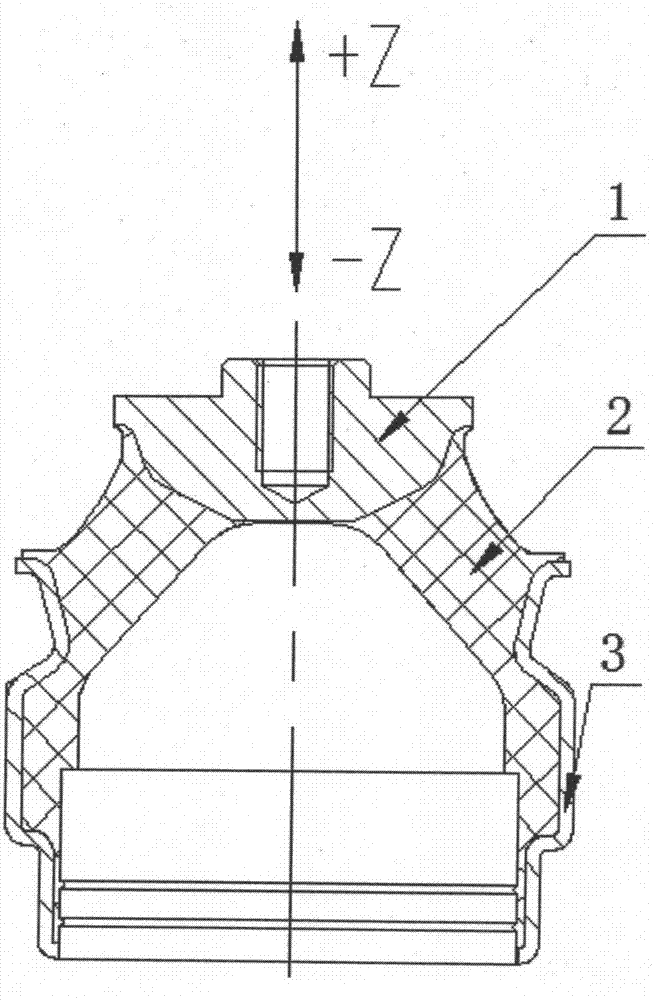

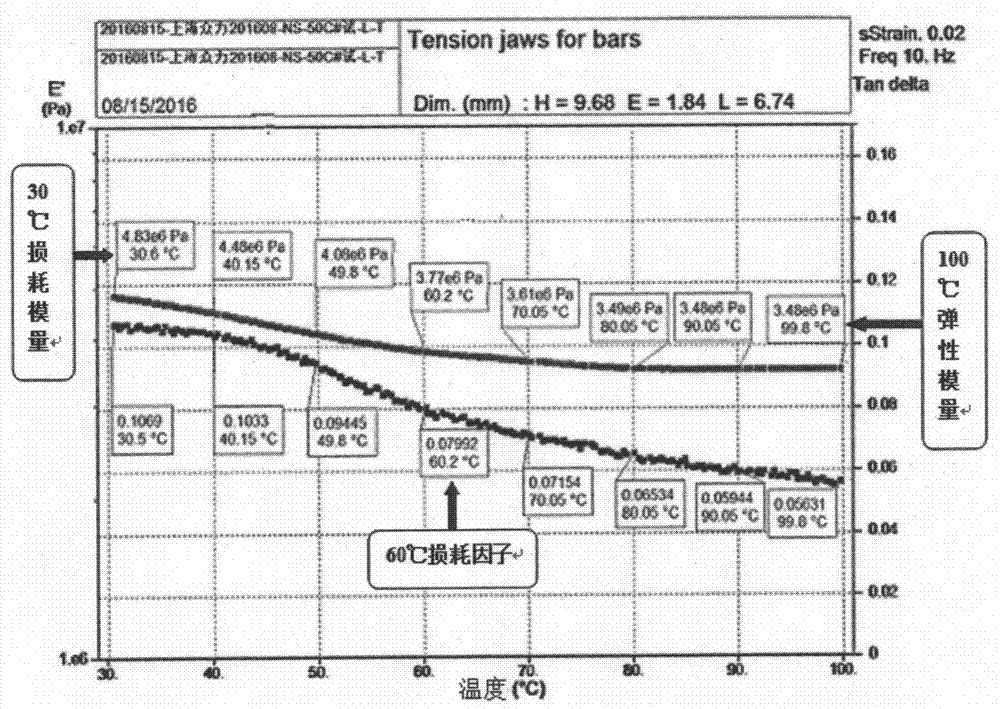

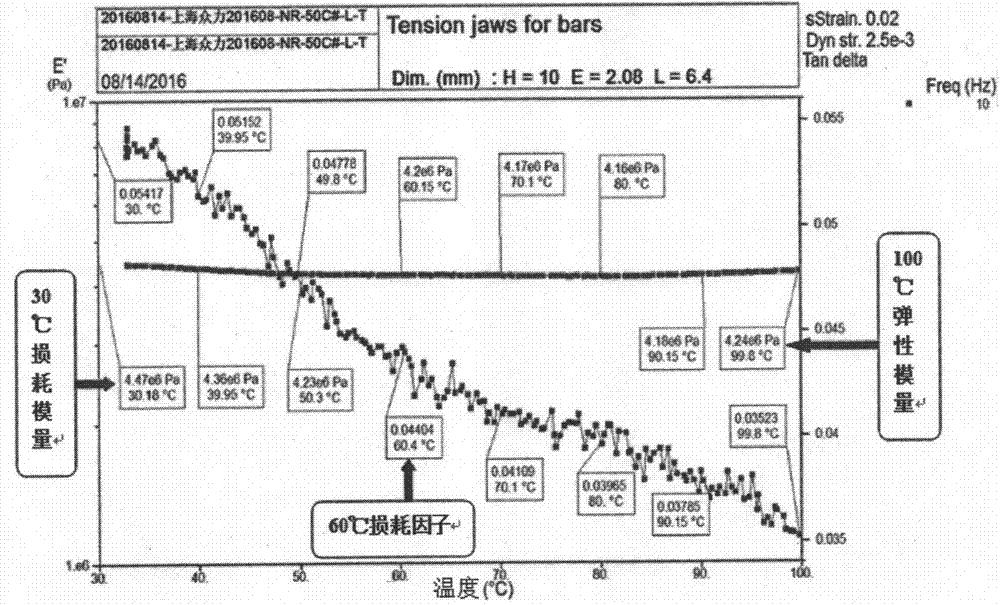

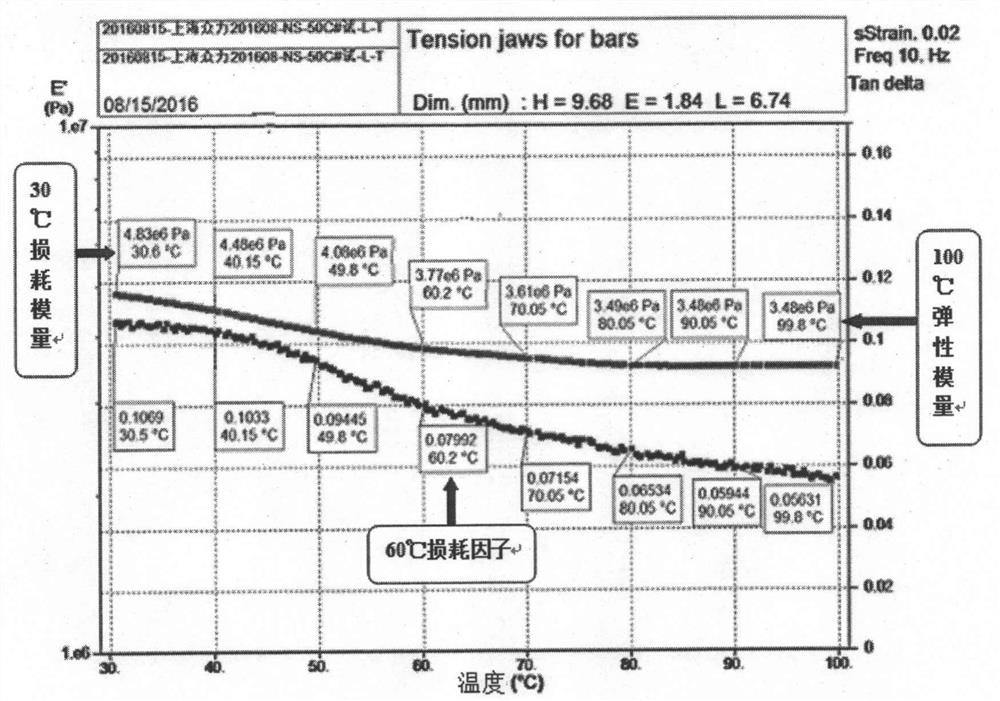

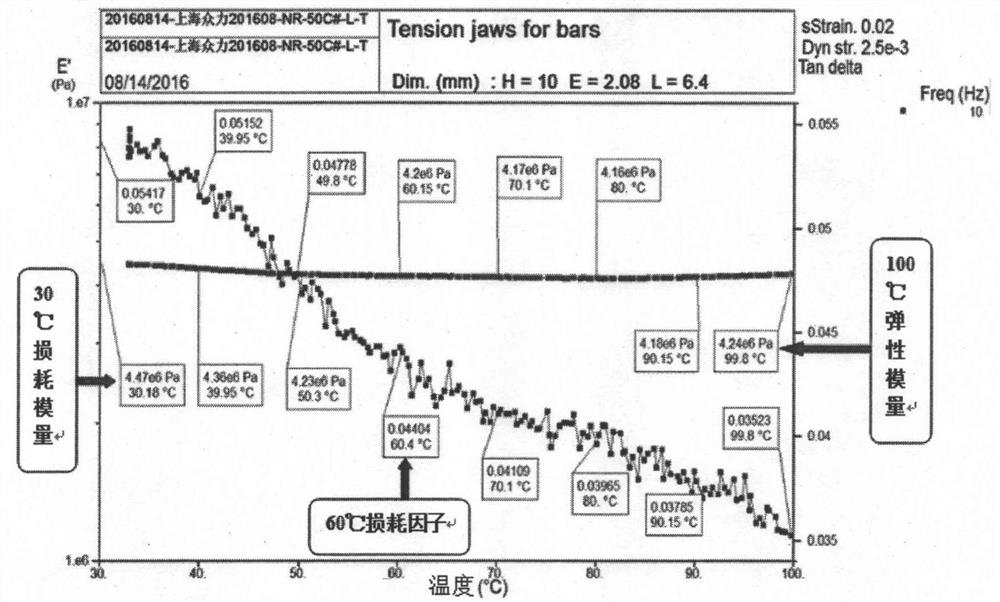

Rubber composition of automobile motor suspension

The invention discloses a rubber composition of automobile motor suspension. The composition is prepared from, by weight, 2.5-3.5 parts of physical antiager, 7-10 parts of activating agent, 5-8 partsof plasticizer, 0.6-1 part of vulcanizing agent, 100 parts of white carbon black wet natural rubber, 1.5-2.5 parts of diaryl secondary amine antiager, 2-3 parts of para-phenylenediamine derivative antiager, 18-25 parts of reinforcing agent, 1.5-2 parts of assistant crosslinker and 1.5-1.8 parts of accelerator. The rubber composition of the automobile motor suspension has the advantages that the high temperature resistance and heat resistance performance is good, and dynamic modulus loss is low; physical property change of a rubber material is little after aging, the strength retaining rate ishigh, and permanent deformation through high-temperature compression is good; the produced motor suspension has low stiffness and good NVH effect, high-temperature creep and high-temperature fatigue performance, and the motor suspension is at the top of the industry and recognized by clients at home and abroad.

Owner:SHANGHAI ZHONGLI INVESTMENT

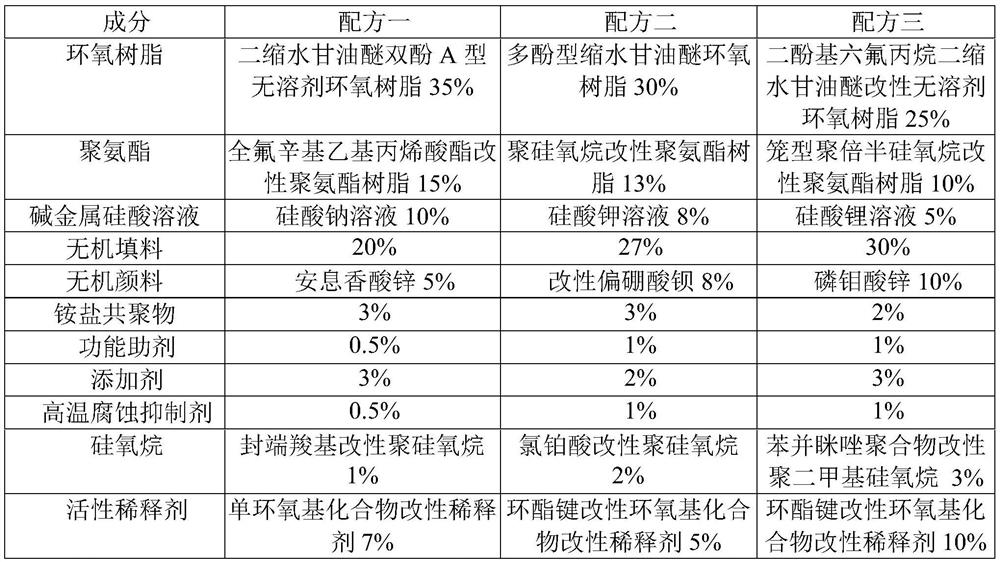

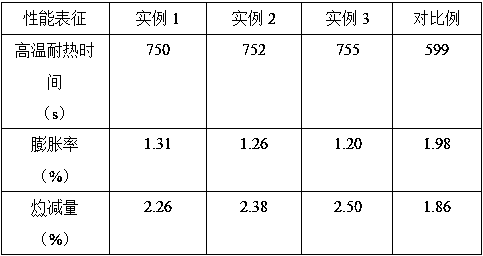

Special epoxy anticorrosive paint for special equipment and preparation method thereof

PendingCN112480785AReduce long-term wear and tearImproved edge retentionAnti-corrosive paintsPolyurea/polyurethane coatingsPolymer scienceSilicic acid

The embodiment of the invention relates to a special epoxy anticorrosive paint for special equipment and a preparation method thereof, the paint is composed of a component A and a component B which are respectively prepared in advance and are uniformly mixed during construction, the mass ratio of the component A to the component B is 1: (0.2-0.3). The component A is prepared from the following components in percentage by mass: 25 to 35 percent of epoxy resin, 10 to 15 percent of polyurethane, 5 to 10 percent of alkali metal silicic acid solution, 20 to 30 percent of inorganic filler, 5 to 10 percent of inorganic pigment, 2 to 3 percent of an ammonium salt copolymer, 0.5 to 1 percent of a functional additive, 2 to 3 percent of an additive, 0.5 to 1 percent of a high-temperature corrosion inhibitor, 1 to 3 percent of siloxane and 5 to 10 percent of a reactive diluent; and the component B is an amine curing cross-linking agent. The special epoxy anticorrosive paint for special equipment provided by the embodiment of the invention can be widely applied to special equipment metal surfaces and special structure metal material surfaces in the special fields of aerospace, military facilities, petrochemical engineering, maritime ships and warships and the like in various high-temperature cold and humid environments to provide anticorrosive protection.

Owner:CHINA SPECIAL EQUIP INSPECTION & RES INST

Preparation method of high performance precoated sand

InactiveCN109047644AImprove liquidityImprove toughnessFoundry mouldsFoundry coresShock resistanceVolumetric Mass Density

The invention relates to a preparation method of high-performance precoated sand, and belongs to the technical field of casting modeling. According to the preparation method, calcium stearate is added, calcium powder is added to increase the density of a sand core, so that the sand grains are arranged more densely, and the strength of a model (core) is improved; at the core making temperature, resin and the calcium stearate are successively softened and melted, the calcium stearate is uniformly distributed in the precoated sand to form an interpenetrating network, the flexibility of the resinis improved, the deflection of the shell model (core) is increased, and thus the thermal toughness is further increased; in the preparation method, silicon nitride has good mechanical properties, goodthermal shock resistance, low temperature creep and stable structure, the silicon nitride is a covalent compound with high bond strength and can form an oxide protective film in air, so that the silicon nitride further has good chemical stability, and the silicon nitride and silicon carbide can form strong bond; and a refractory filler composed of silicon nitride powder, fly ash, alumina powder and silicon carbide powder is added into the precoated sand to enable the high temperature resistance time of the precoated sand to be prolonged.

Owner:佛山齐安建筑科技有限公司

Green low-creep MgO-C brick and preparation method thereof

InactiveCN110550922AImprove bindingImprove environmental protection effectParaffin waxHigh resistance

The invention relates to a green low-creep MgO-C brick and a preparation method thereof. The technical scheme of the preparation method comprises the steps: performing batching on fused magnesia finepowder, titanium diboride fine powder and triethanolamine at a mass ratio of 100:(2-4):(4-6), performing even mixing at 130-135 DEG C in a vertical heating mixer so as to obtain a mixed fine powder material, performing batching on fused magnesia particles, the mixed fine powder powder, flake graphite and boric anhydride at a mass ratio of 100:(40-45):(3-6):(2-3), performing even mixing at 140-150DEG C in the vertical heating mixer so as to obtain a premix, adding glycerin with an amount of 4-5% of the weight of the premix and liquid paraffin with an amount of 2-3% of the weight of the premixto the premix, performing mixing at 160-165 DEG C in the vertical heating mixer so as to obtain a mixed material, performing press forming on the mixed material under 55-65 MPa, and performing heat treatment at 220-250 DEG C for 60-90 minutes so as to obtain the green low-creep MgO-C brick. The process is simple and environmentally friendly, the prepared product has a good environmental protectioneffect, low creep at high temperature, hydration resistance and high resistance to slag corrosion.

Owner:WUHAN UNIV OF SCI & TECH +1

Preparation method of alumina ceramics for automotive pressure sensors

The invention discloses a preparation method of alumina ceramics for automotive pressure sensors. The preparation method comprises the following steps: A, preparing a raw material from 95-97 wt% of alpha-Al2O3, 1-2 wt% of kaolin, 0.5-2 wt% of calcium carbonate, 0.5-1 wt% of silica and 0.3-0.7 wt% of zirconium silicate, and uniformly mixing PVA17-99 and n-octyl alcohol; B, ball-milling; C, conducting spray granulation; D, dry-pressing and sintering; E, vibro-milling; and F, surface metallization. Through methods of using alumina ceramics as a matrix, adding zirconium silicate, improving ball-milling mode and conducting surface second metallization, density of the ceramic product reaches 3.69 g / cm<3> or above; elasticity modulus reaches about 310 Gpa; coefficient of thermal expansion is about 5*10<-6> / DEG C (from 25-500 DEG C); and flexural strength is about 288 Mpa.

Owner:HUNAN MEICHENG CERAMIC TECH

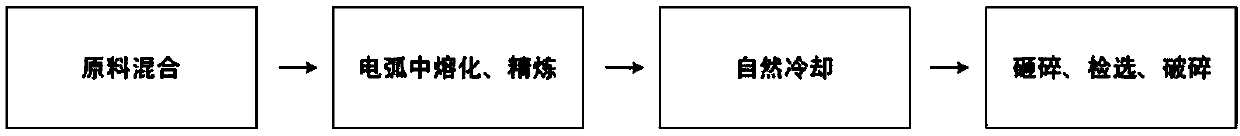

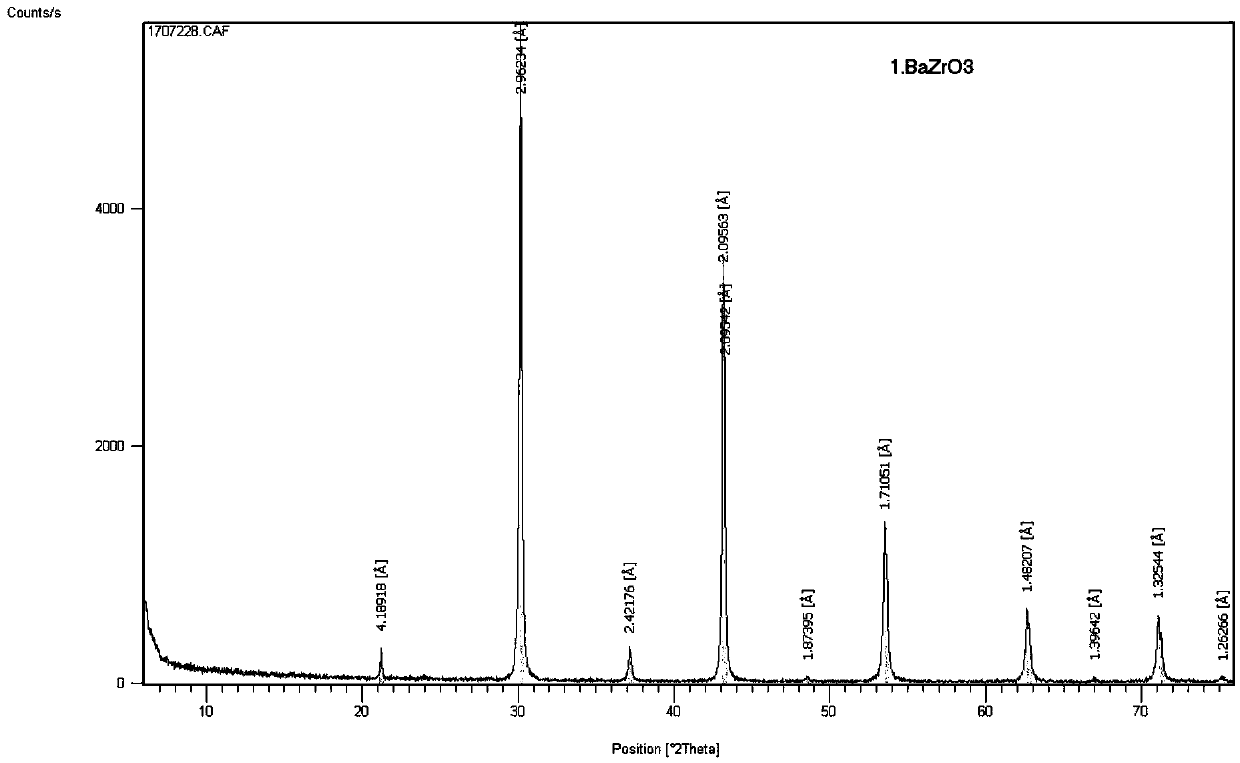

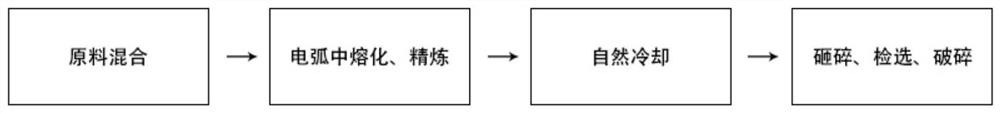

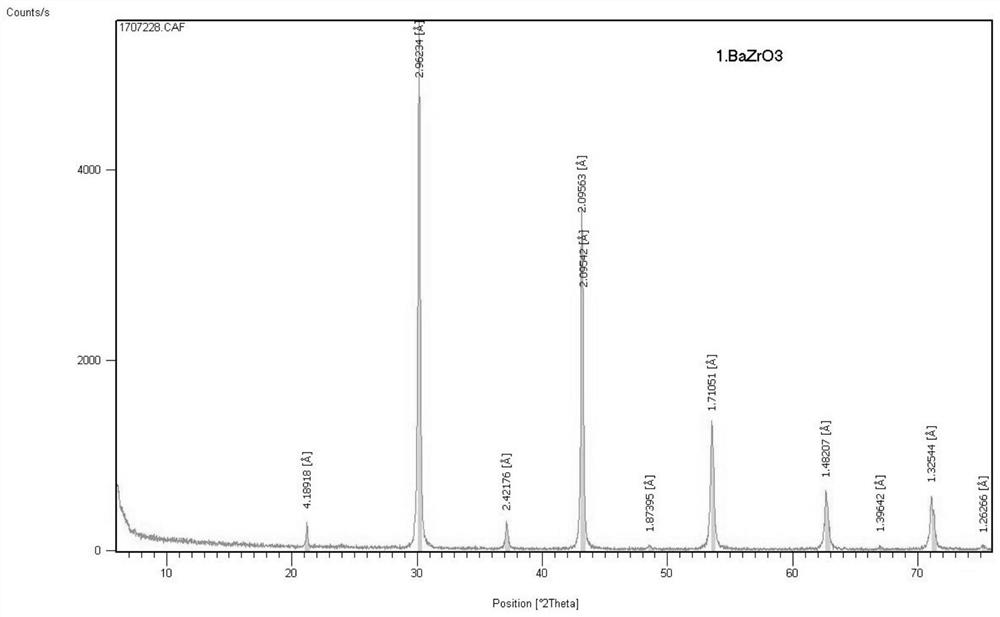

Method for preparing electrically-fused barium zirconate

The invention discloses a method for preparing electrically-fused barium zirconate. The method comprises the following steps: 1: putting powdery and granular monoclinic zirconia and any one of ceriumoxide or cerium carbonate into a mixer, uniformly mixing to form a mixture; 2: putting the mixture into an electric arc, fusing and refining at the temperature of 2600-3000 DEG C till the mixture is fully fused into a molten state; 3: naturally cooling the mixture in the molten state to below 50 DEG C to form an offwhite solid finished product; and 4: breaking the offwhite solid finished product into pieces, selecting and crushing to form barium zirconate powder. The method disclosed by the invention has the beneficial effects that the powder which is all barium zirconate phase is obtained through an electrofusion method and has the characteristics that the porosity is low, the volume density is high, particles of various particle sizes and fine powder can be processed, the high temperature volume stability is good and the like; and the problems that the prepared barium zirconate powder is low in purity and contains unreacted barium carbonate phases are solved.

Owner:郑州振中电熔新材料有限公司

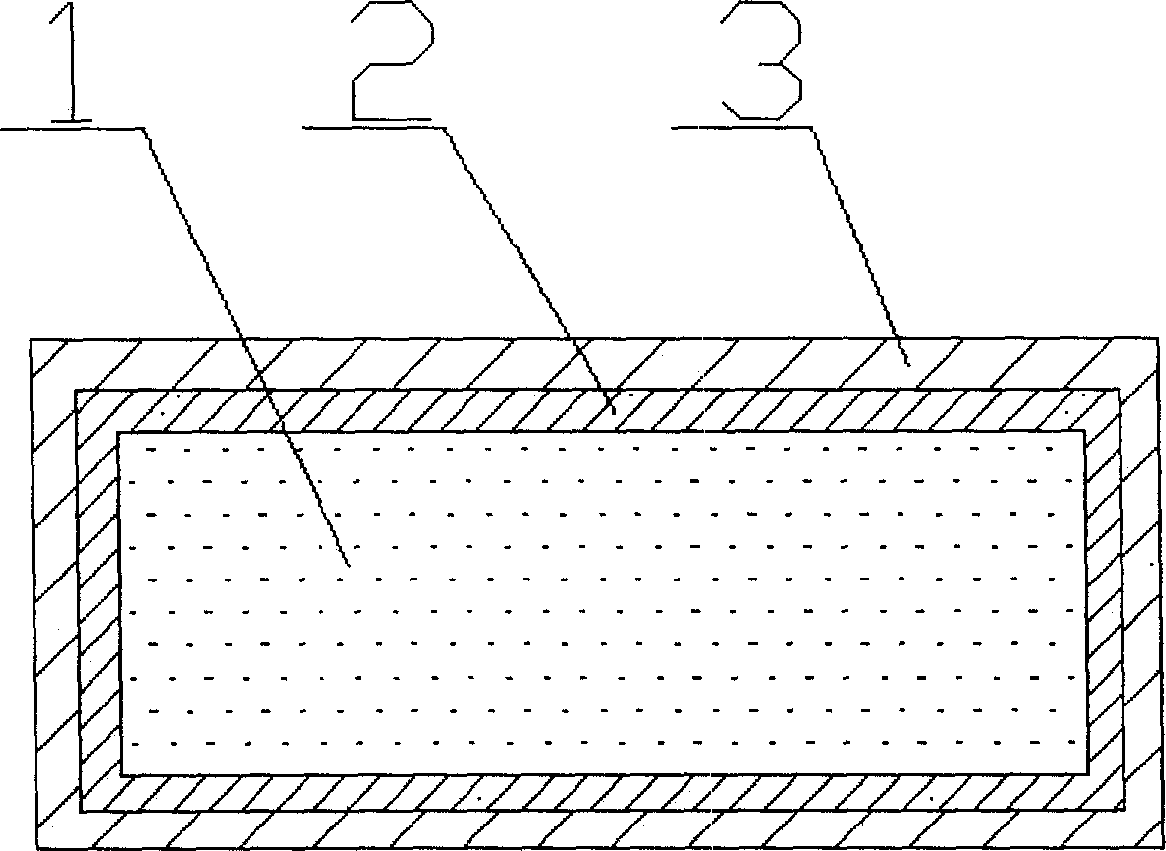

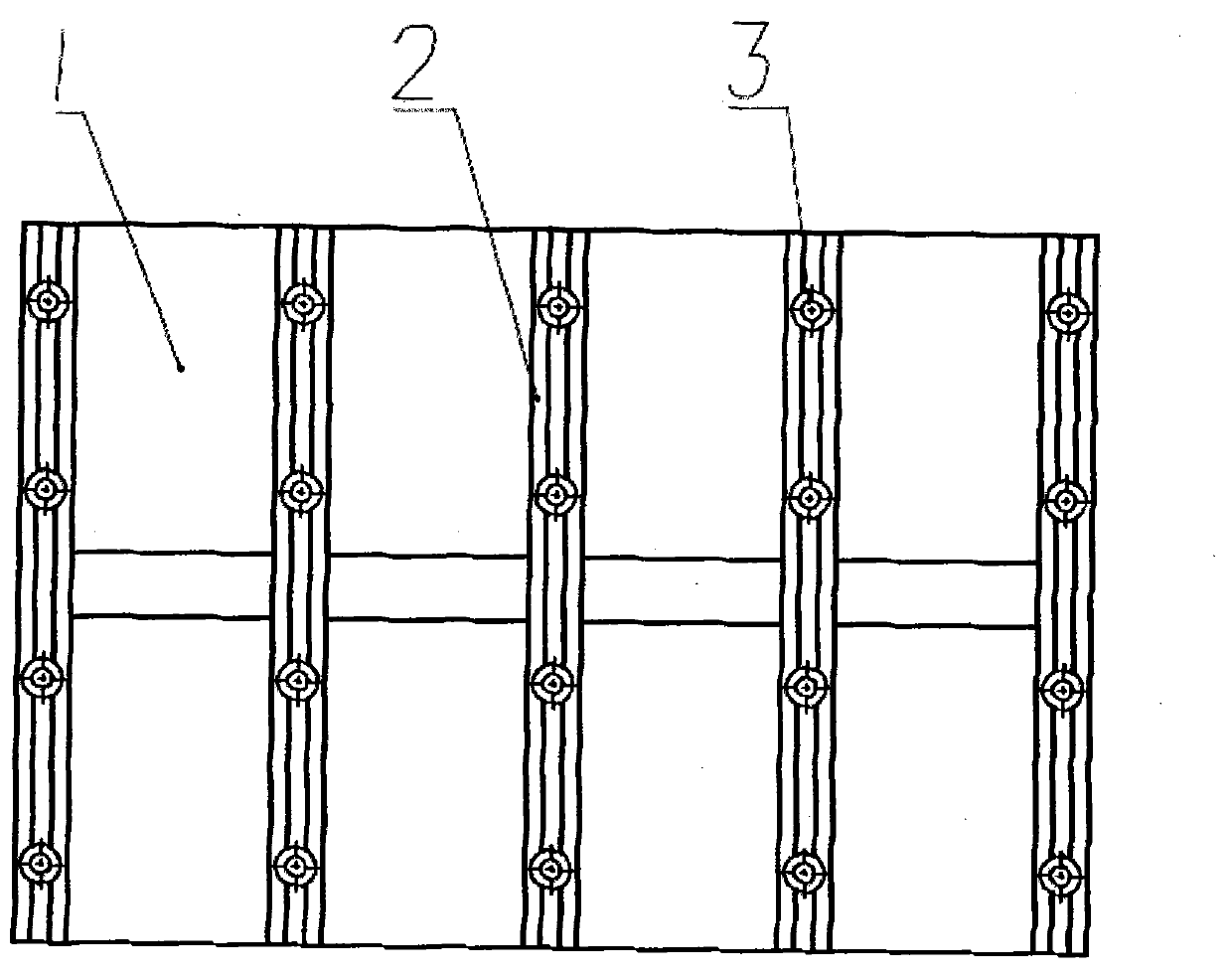

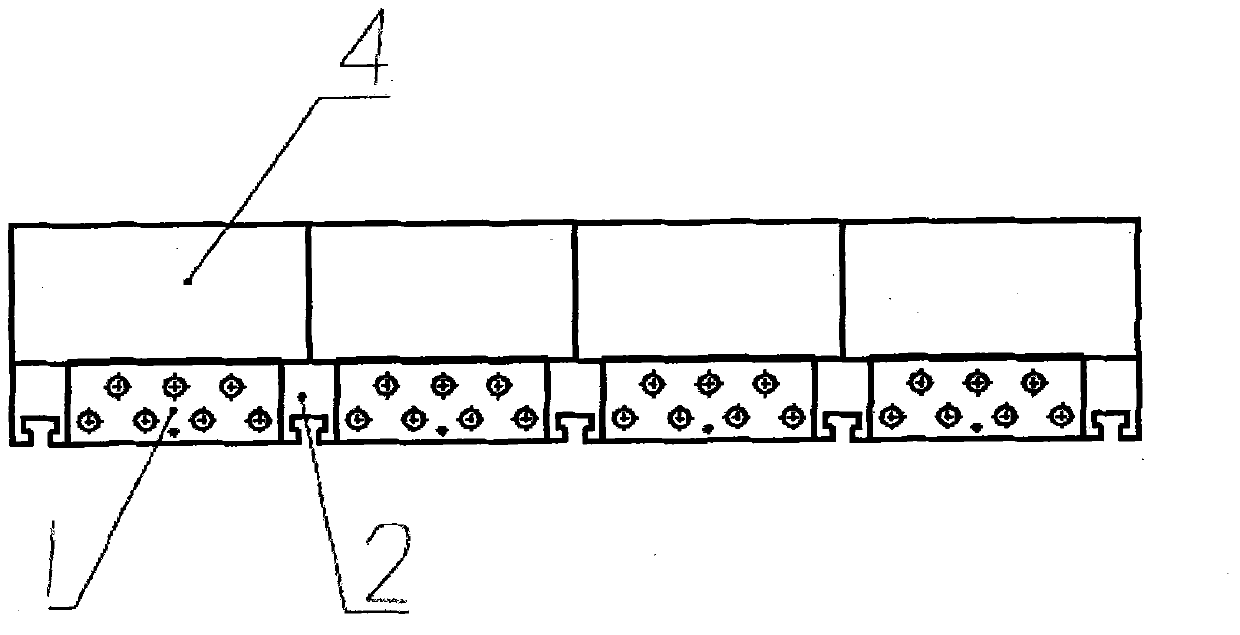

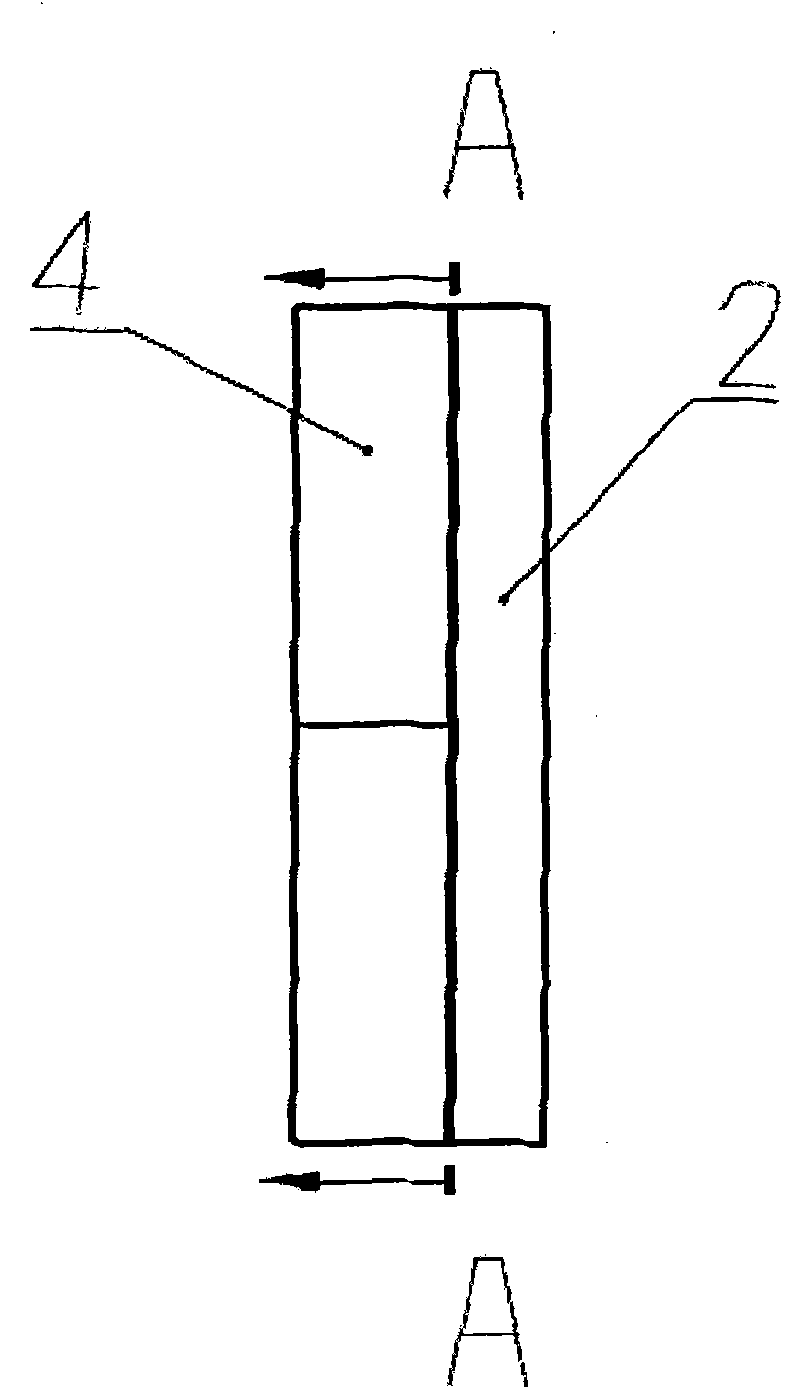

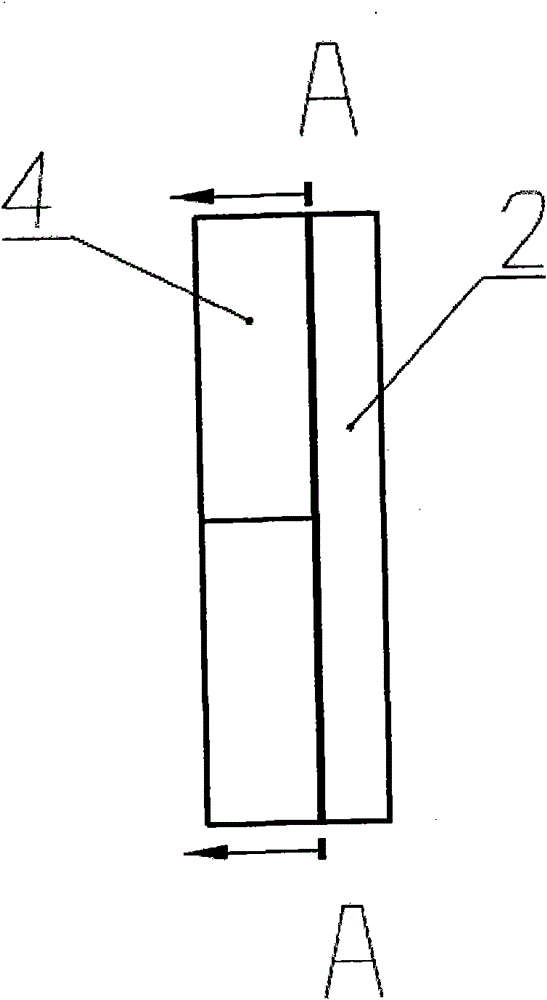

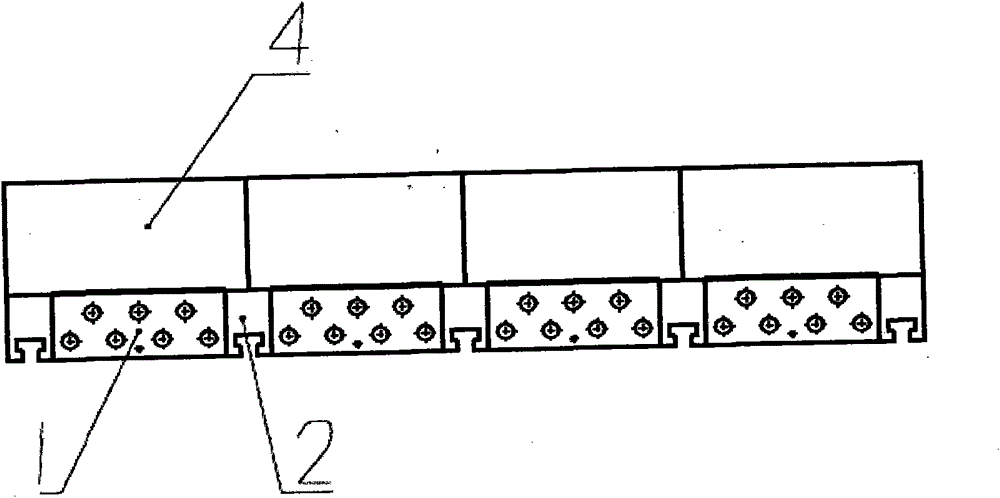

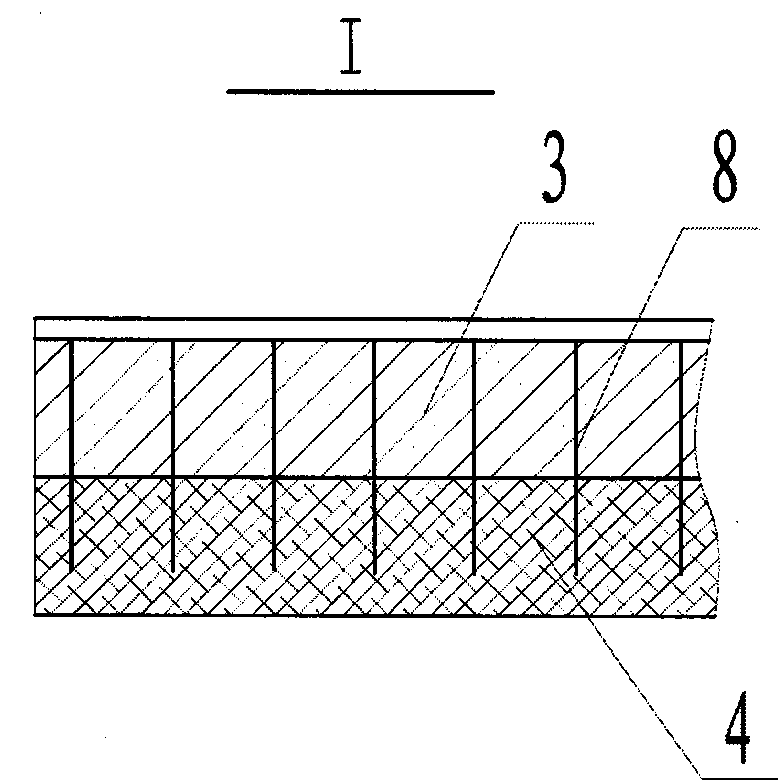

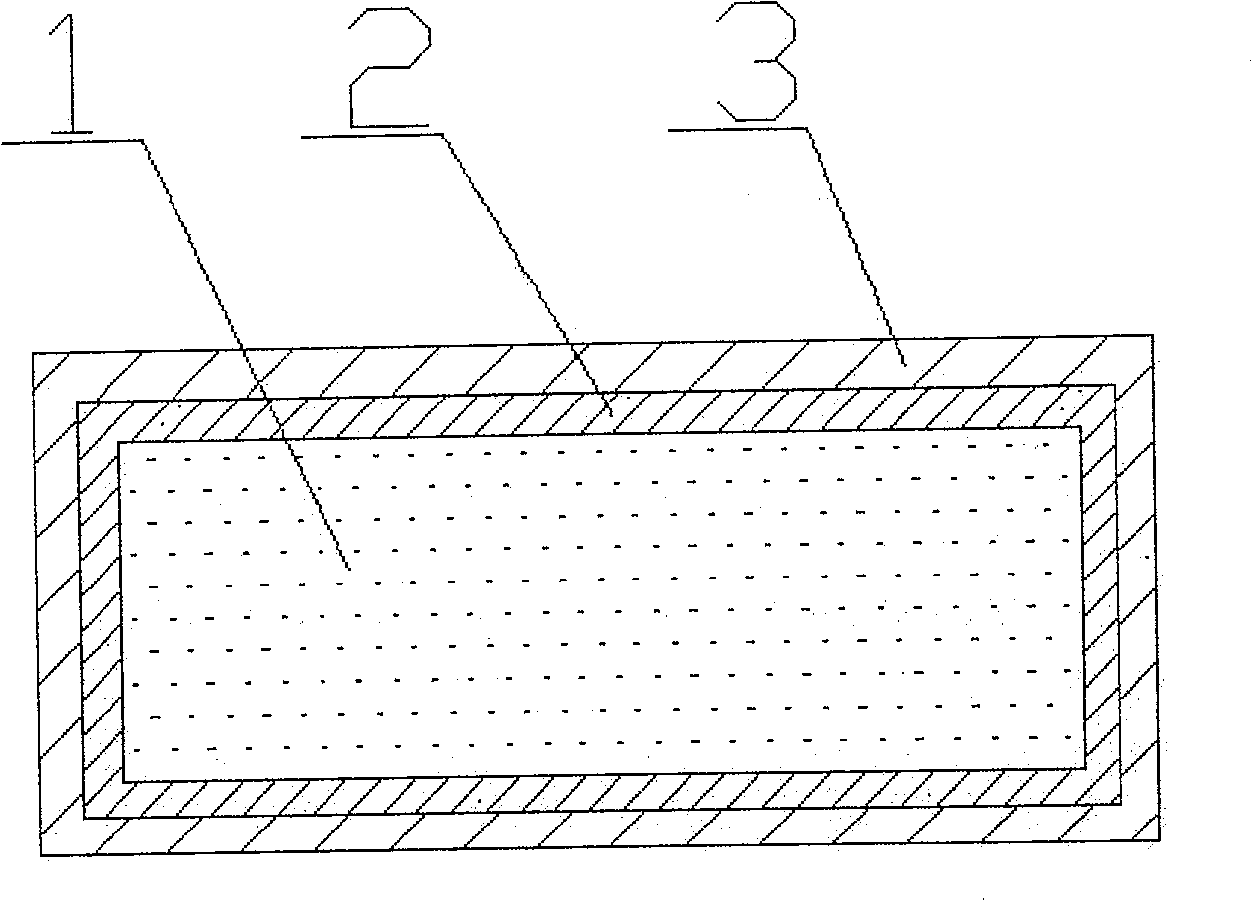

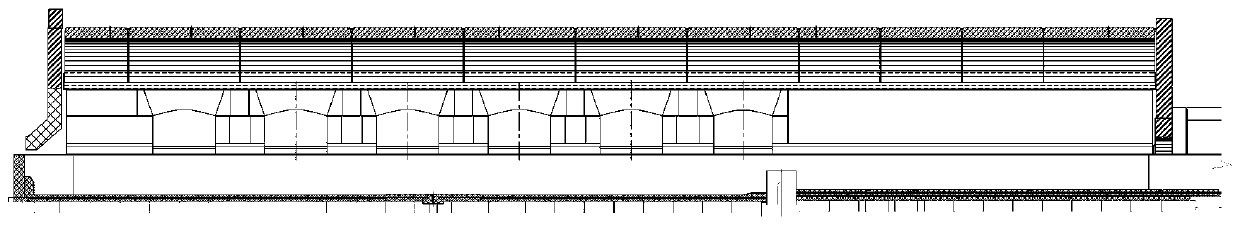

Heating/heat insulation platform of heat former

The invention relates to a heating / heat insulation platform of a heat former, comprising heating platforms and heat insulating platforms, wherein the each heat insulating platform is made form fromcorundum-mullite; the eight heat insulating platforms are arranged in two rows; the middle of each heat insulating platform is coated with AK04-4 high-temperature organic glue; LYHG-23 high-temperature adhesive is coated around the AK04-4 high-temperature organic glue; the heating platforms are respectively arranged on the glue coated parts of the heat insulating platforms; the heating platform is made from recrystallized silicon carbide; and a trapezoidal groove beam and a transversal beam are arranged between the heating platforms, provided with through holes for arranging bolts, and made from high-temperature alloy Ra602H. The invention has the advantages that the each heat insulating platform is made from the recrystallized silicon carbide, so that the high-temperature creep is low, the deformation is low when in use for a long time at high temperature, and the processing precision of parts is enhanced; as the resistance of recrystallized silicon carbide is large, overlarge current cannot be generated between the heating tube and heating platforms when the heating tube is broken down, so the heating tube and the heating platforms cannot be welded together, and the maintenance is convenient.

Owner:SHENYANG AIRCRAFT CORP

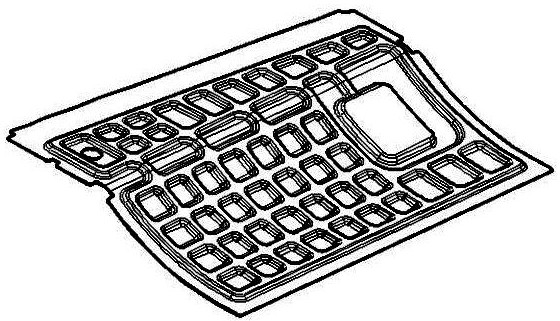

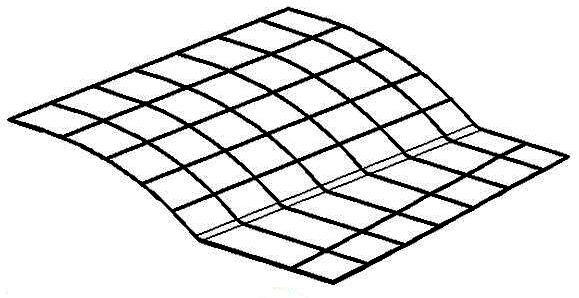

Complex molded surface pneumatic loading superplastic forming diffusion bonding method

The invention discloses a complex molded surface pneumatic loading superplastic forming diffusion bonding method, and belongs to the technical field of sheet metal hot working. The method is characterized by comprising the following steps of a, pre-forming an upper panel, a lower panel and an auxiliary plate of a part by adopting a concave-convex die of a titanium alloy hot forming die; b, drawing an outline of the diffusion junction area; c, carving crisscrossed vent grooves in the auxiliary plate; d, engraving an air path; e, spraying chemical milling glue on the part; f, carving a superplastic forming area pattern of the part; g, sealing and welding; h, completing diffusion connection of the upper panel and the lower panel; i, completing superplastic forming of the upper panel; and j, turning off a power supply of a machine tool, and taking out the part after the die is cooled to 650-700 DEG C. The problem that the welding rate of titanium alloy complex molded surface pneumatic loading superplastic forming diffusion bonding is not enough can be effectively solved, the service life of a superplastic forming diffusion bonding die can be prolonged, and the repair frequency of the die can be reduced.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

A method for preparing high-temperature non-oxide eutectic ultrafine powder by thermal polymerization reaction

The invention discloses a method for preparing high-temperature non-oxide eutectic superfine powder by a heat polymerization reaction. According to the method disclosed by the invention, compound powder is prepared by adopting heat polymerization and the compound powder reacts with silicon nitride to prepare eutectic ceramic powder; the disadvantages that the density of a compound ceramic material sintered by the reaction is low, the hot pressing sintering temperature strength is poor and the like are solved; the density and strength of a product are effectively improved; a special temperature control curve is adopted and the prepared eutectic ceramic powder has the advantages of small thermal expansion coefficient, good thermal shock resistance property, small high-temperature creep and the like and the application range of the product is relatively wide; and a preparation process is simple and the product has stable performances and is suitable for industrial production.

Owner:HAINAN VOCATIONAL COLLEGE OF SCI & TECH

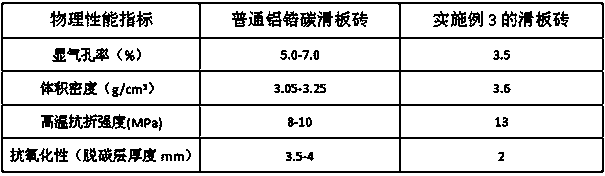

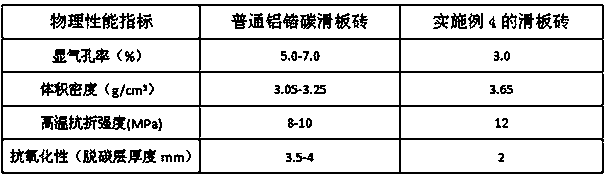

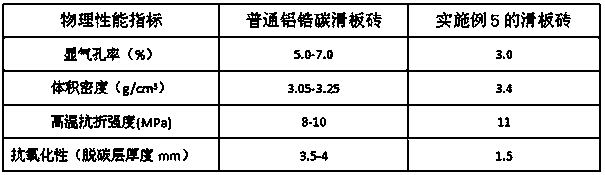

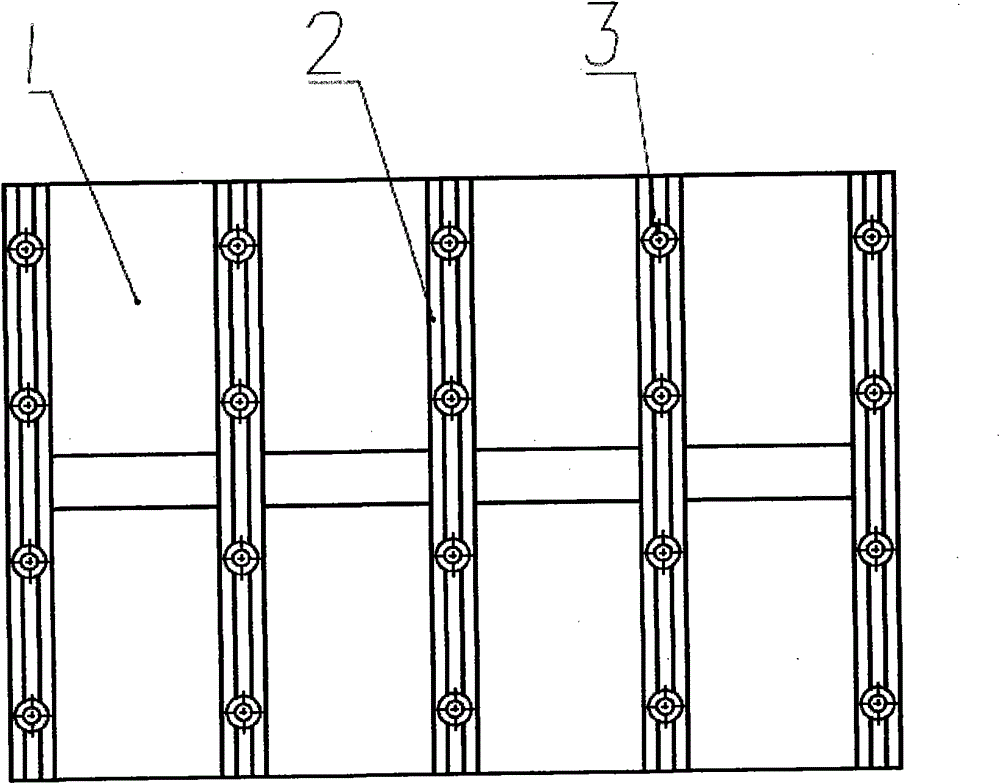

Sliding brick with carbon nanotube combined with ferrosilicon nitride and preparation method thereof

The invention relates to a sliding brick containing ferro-silicon nitride and combining with a carbon nano tube and a preparation method of the sliding brick. The sliding brick is prepared from the following raw materials in percentage by weight: 55 to 60 percent of tabular corundum, 15 to 25 percent of white corundum, 3 to 5 percent of alumina powder, 15 to 20 percent of ferro-silicon nitride, 0.5 to 1.5 percent of carbon nano tube, and an additionally added binding agent is 2 to 5 percent of the total quantity of the raw materials of the sliding brick. The preparation method comprises batching, mixing, mechanical pressing, drying, roasting, oil immersion treatment, light roasting carbonization treatment, hooping, polishing, surface coating and finishing a product. The sliding brick provided by the invention is stable in structure, has excellent thermal shock resistance and erosion resistance, continuous sliding times are many, the service life is long and the popularization is facilitated.

Owner:HENAN RONGJIN HIGH TEMPERATRUE MATERIALS CO LTD

Preparation method of low-zirconium mullite cast steel brick

The invention relates to a preparation method of a low-zirconium mullite cast steel brick, and belongs to the field of preparation of refractory materials. The raw material formula of the low-zirconium mullite cast steel brick provided by the invention comprises electrically smelted mullite, zirconium oxide, Guangxi white clay, andalusite, kyanite and lignin. According to the method provided by the invention, type and grain size of the raw materials are selected to be matched with the sintering temperature and time provided by the invention, so that the prepared low-zirconium mullite cast steel brick has the characteristics of excellent scouring resistance, high temperature resistance, small creep deformation, high compression strength, good thermal stability and the like, and is suitable for being used in large steel ingot casting in nuclear power products.

Owner:四川锦圆耐材有限公司

Heating/heat insulation platform of heat former

InactiveCN101905530BUse small deformationSmall creep at high temperatureElectrical resistance and conductanceAdhesive

The invention relates to a heating / heat insulation platform of a heat former, comprising heating platforms and heat insulating platforms, wherein the each heat insulating platform is made form fromcorundum-mullite; the eight heat insulating platforms are arranged in two rows; the middle of each heat insulating platform is coated with AK04-4 high-temperature organic glue; LYHG-23 high-temperature adhesive is coated around the AK04-4 high-temperature organic glue; the heating platforms are respectively arranged on the glue coated parts of the heat insulating platforms; the heating platform is made from recrystallized silicon carbide; and a trapezoidal groove beam and a transversal beam are arranged between the heating platforms, provided with through holes for arranging bolts, and made from high-temperature alloy Ra602H. The invention has the advantages that the each heat insulating platform is made from the recrystallized silicon carbide, so that the high-temperature creep is low, the deformation is low when in use for a long time at high temperature, and the processing precision of parts is enhanced; as the resistance of recrystallized silicon carbide is large, overlarge current cannot be generated between the heating tube and heating platforms when the heating tube is broken down, so the heating tube and the heating platforms cannot be welded together, and the maintenance is convenient.

Owner:SHENYANG AIRCRAFT CORP

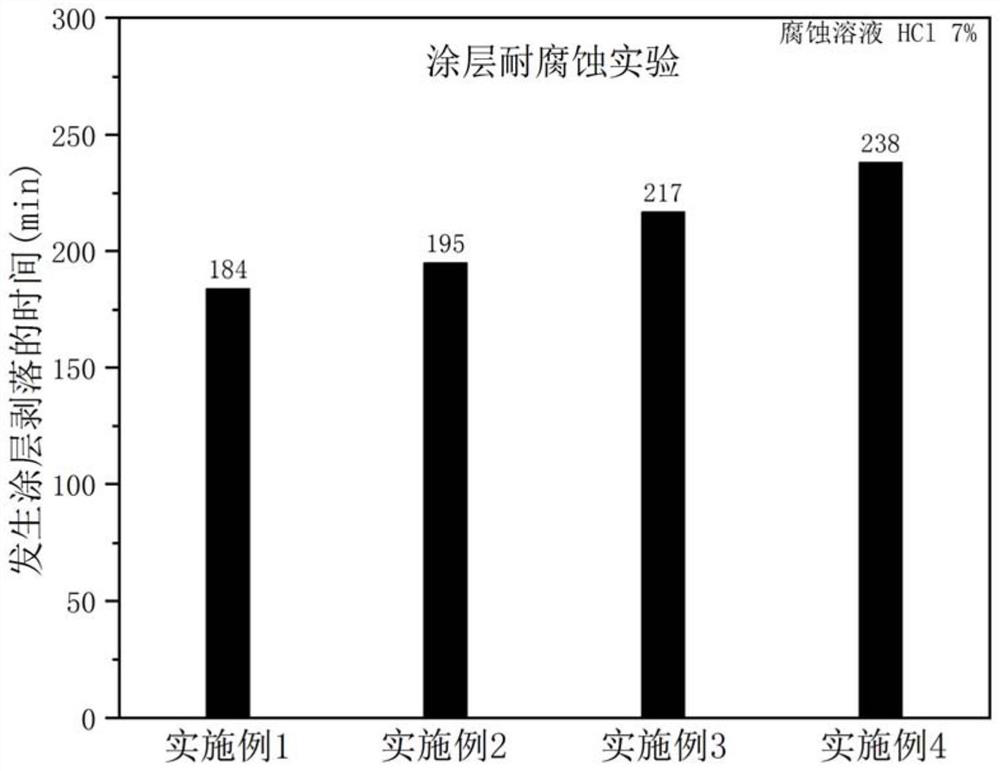

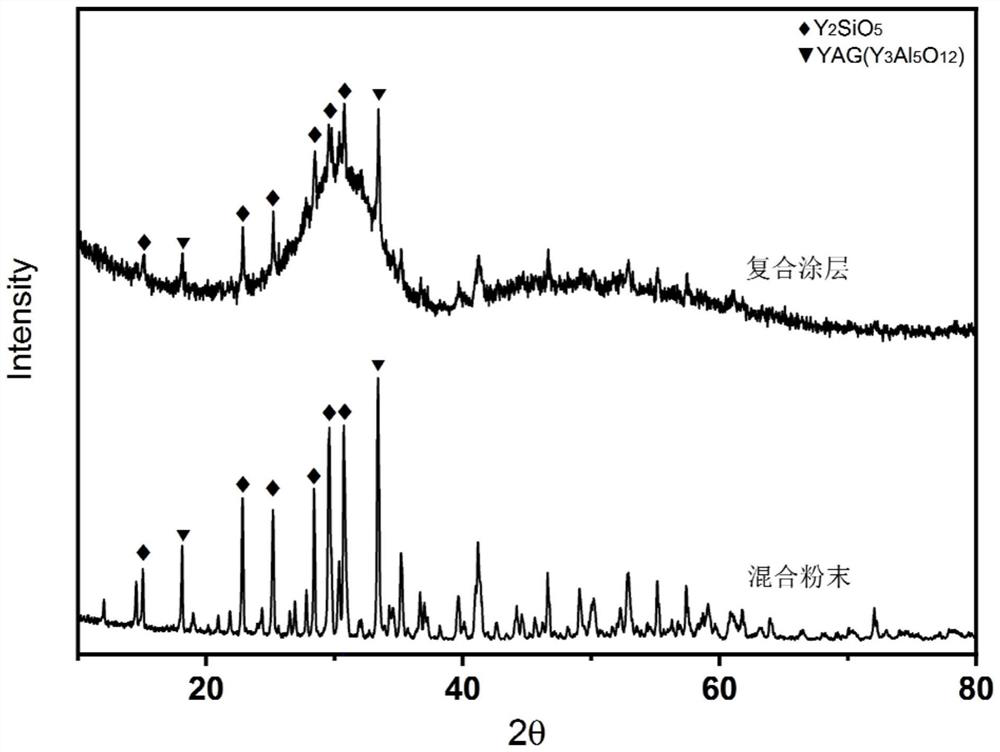

A kind of rare earth metal salt ceramic composite coating and its preparation method and application

ActiveCN113584417BUniform tissue structureUniform compositionMolten spray coatingElectric discharge tubesMischmetalCeramic composite

The invention relates to a rare earth metal salt ceramic composite coating, a preparation method and application thereof, and belongs to the technical field of plasma spraying. put Y 2 O 3 , Al 2 O 3 and SiO 2 Powder, Mix, Prepare Y 2 SiO 5 and Y 3 Al 5 O 12 The mixed powder of the mixed powder was plasma sprayed on the surface of the pretreated substrate to obtain Y 2 SiO 5 ‑Y 3 Al 5 O 12 Composite coating. Y in composite coating 2 SiO 5 Amorphous Y 2 SiO 5 Structure with a mass fraction of 60‑75%, Y 3 Al 5 O 12 For the cubic crystal structure. Amorphous Y 2 SiO 5 As an amorphous material, it is more uniform in structure and composition, and the cubic crystal structure of Y 3 Al 5 O 12 Excellent corrosion resistance. Y 2 SiO 5 ‑Y 3 Al 5 O 12 The composite coating incorporates amorphous Y 2 SiO 5 and Y 3 Al 5 O 12 The advantages are better plasma etching resistance and longer service life.

Owner:CHONGQING GENORI IND CO LTD

A kind of automobile engine suspension rubber composition

The invention discloses a rubber composition of automobile motor suspension. The composition is prepared from, by weight, 2.5-3.5 parts of physical antiager, 7-10 parts of activating agent, 5-8 partsof plasticizer, 0.6-1 part of vulcanizing agent, 100 parts of white carbon black wet natural rubber, 1.5-2.5 parts of diaryl secondary amine antiager, 2-3 parts of para-phenylenediamine derivative antiager, 18-25 parts of reinforcing agent, 1.5-2 parts of assistant crosslinker and 1.5-1.8 parts of accelerator. The rubber composition of the automobile motor suspension has the advantages that the high temperature resistance and heat resistance performance is good, and dynamic modulus loss is low; physical property change of a rubber material is little after aging, the strength retaining rate ishigh, and permanent deformation through high-temperature compression is good; the produced motor suspension has low stiffness and good NVH effect, high-temperature creep and high-temperature fatigue performance, and the motor suspension is at the top of the industry and recognized by clients at home and abroad.

Owner:SHANGHAI ZHONGLI INVESTMENT

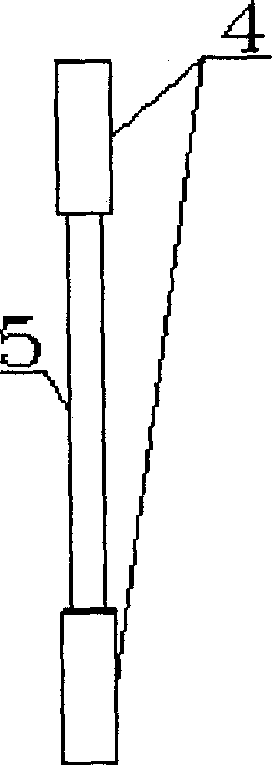

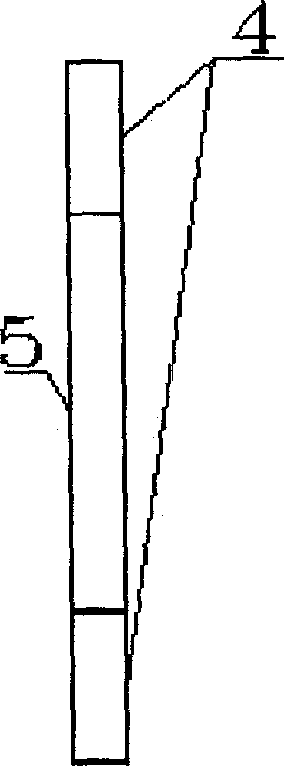

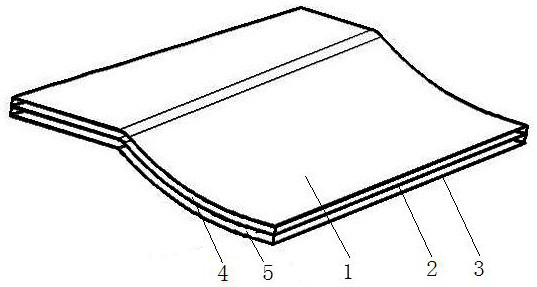

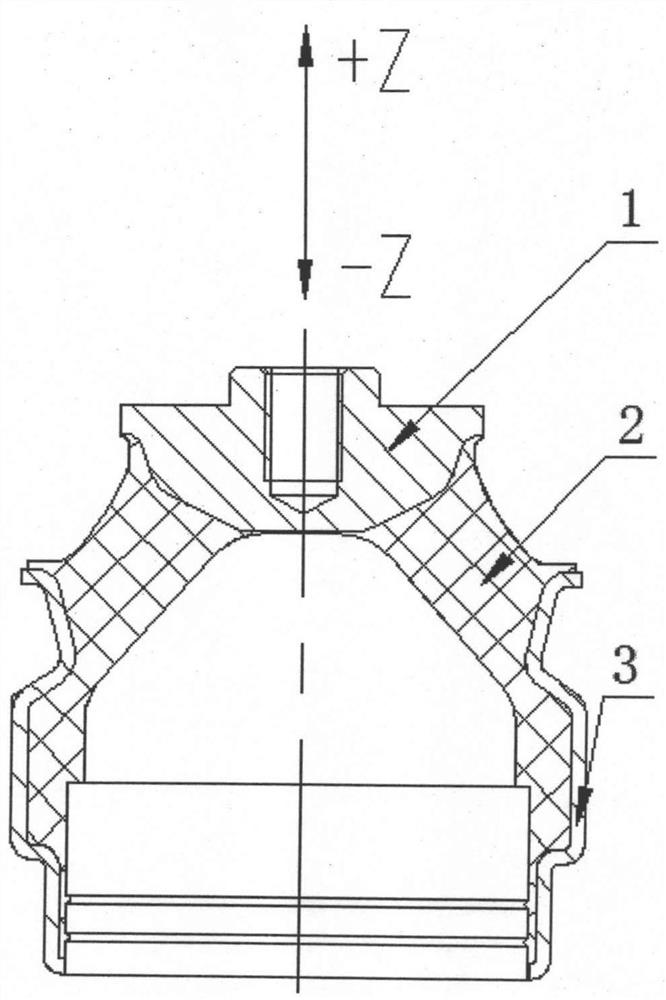

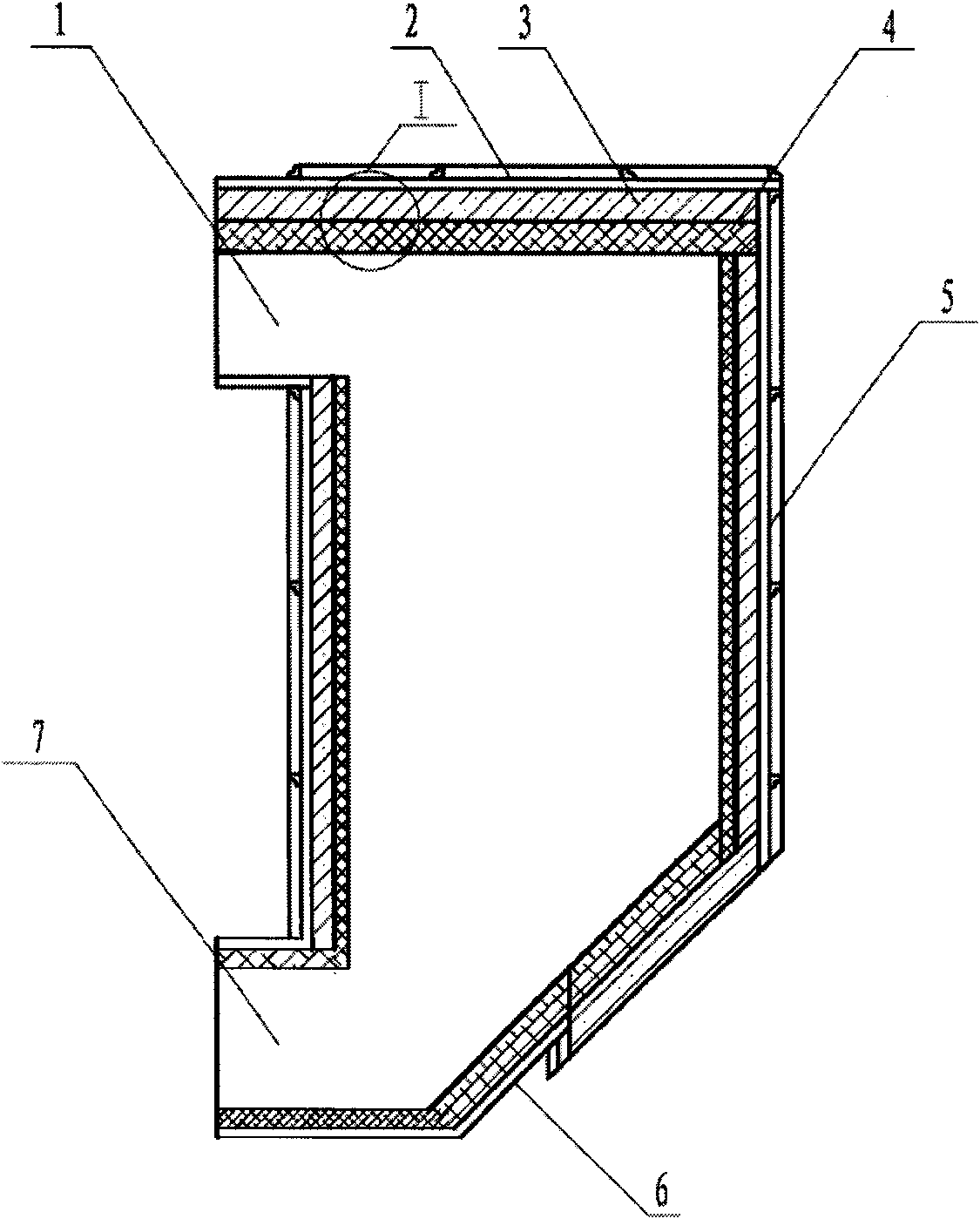

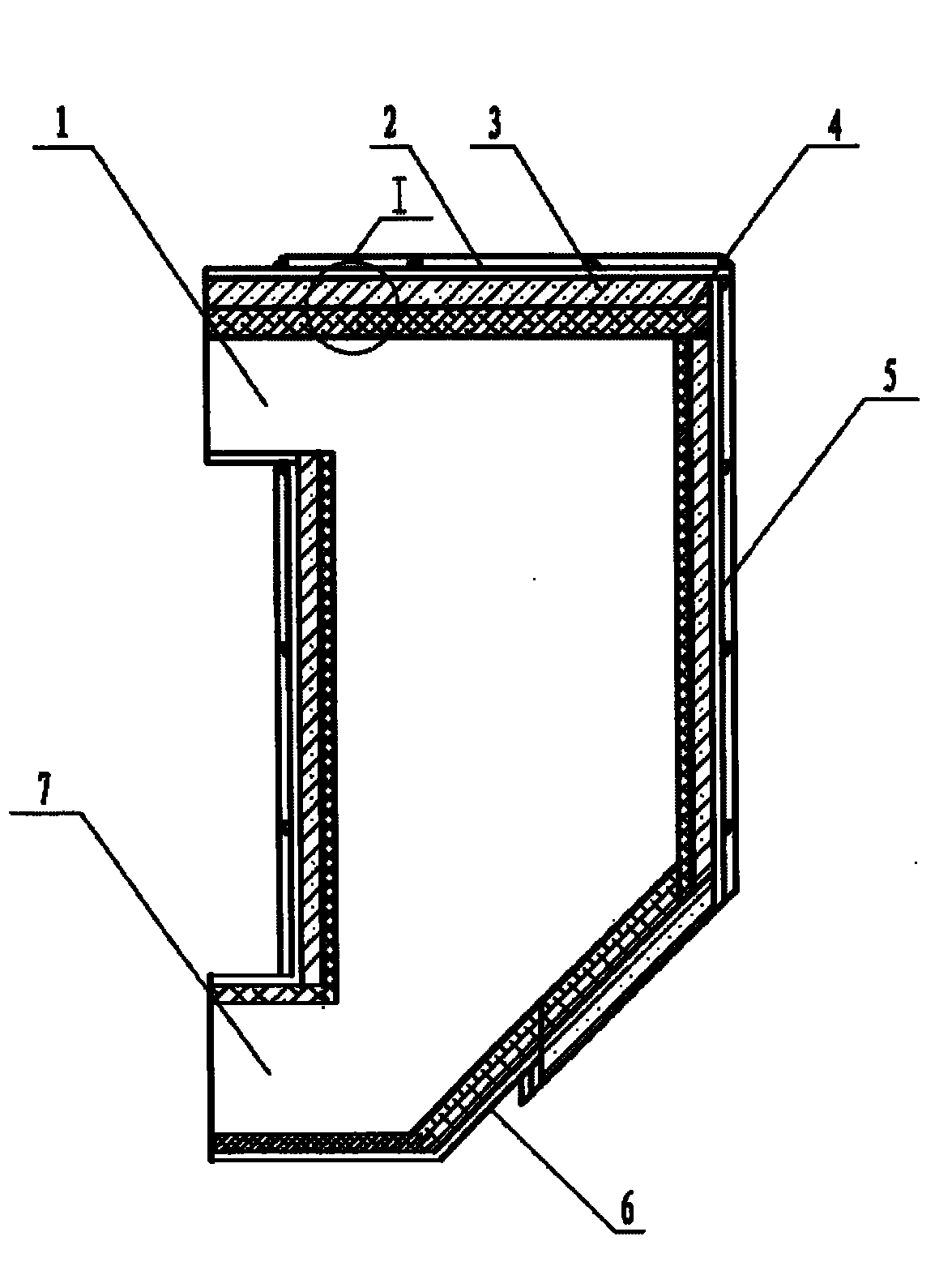

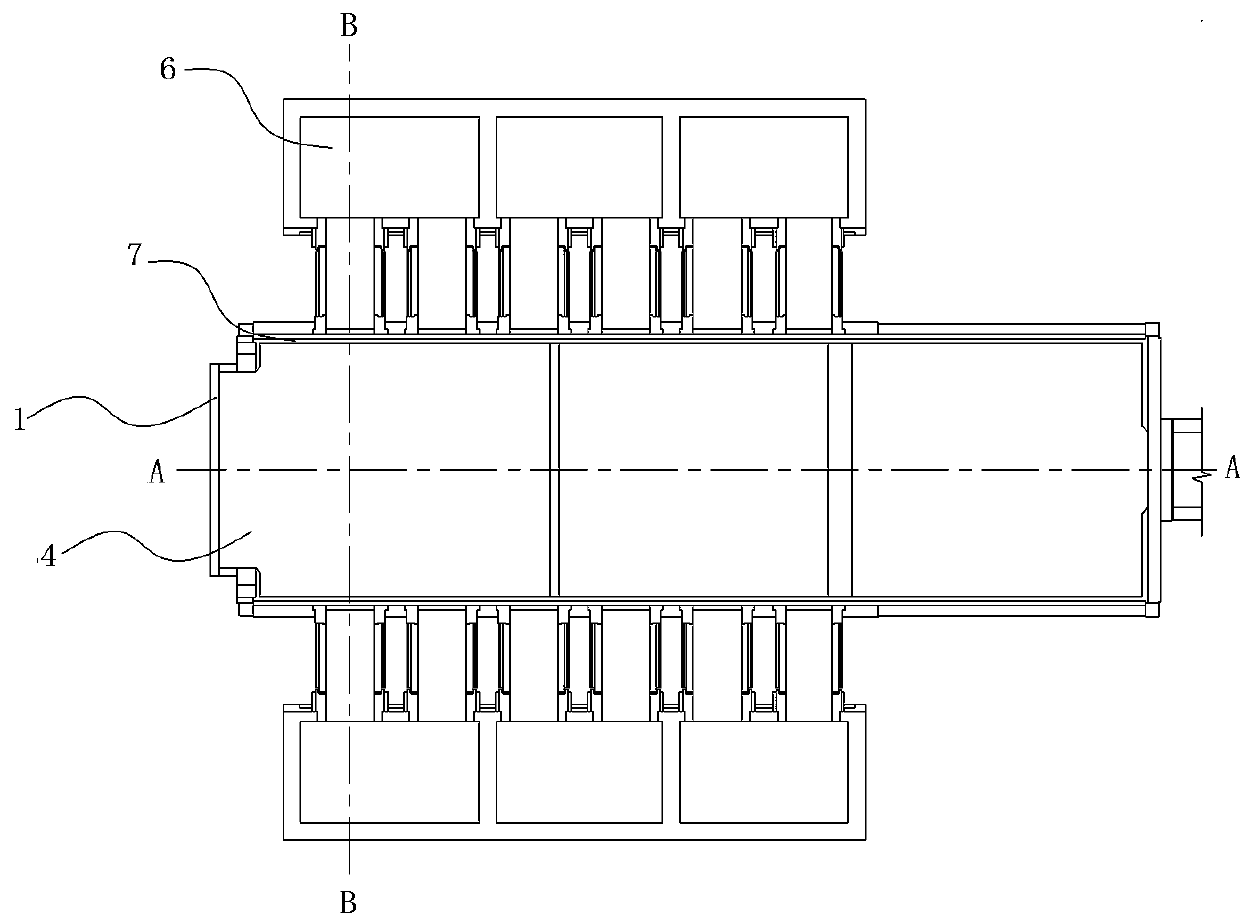

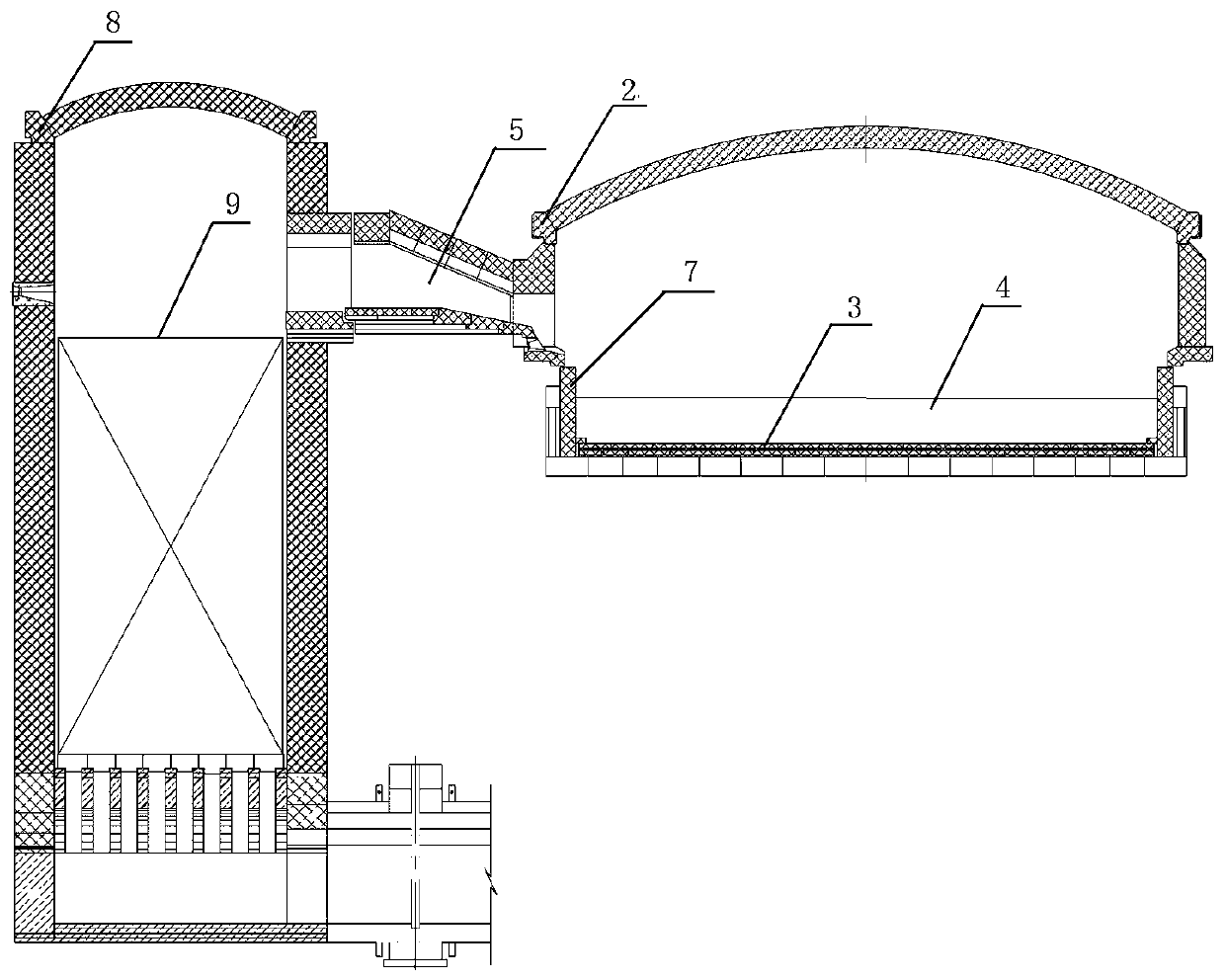

Flue gas denitration reactor

InactiveCN101829497ASmall creep at high temperatureHigh durabilityDispersed particle separationFlue gasEngineering

The invention relates to a flue gas denitration reactor. An internal layer of a reactor shell is a wear-resisting layer (4); a heat-insulating layer (3) is coated outside the wear-resisting layer (4); the outside of the heat-insulating layer (3) is provided with a lateral plate (5), a top plate (2) and an inclined plate (6); the top plate (2) and the lateral plate (5) form a first opening (1) together on the upper part of the reactor shell; and the inclined plate (6) and the lateral plate (5) form a second opening (7) together on the lower part of the reactor shell. The flue gas denitration reactor is also provided with a heat-resisting steel bar (8) welded on the inner wall of the shell; the heat-insulating layer (3) is fixedly supported on the heat-resisting steel bar (8); the wear-resisting layer (4) is also fixedly supported on the heat-resisting steel bar (8); the heat-insulating layer of the wear-resisting layer is positioned on the inner side of the reactor shell, so that a stressed structure of the shell directly contacts external environment; and the shell is in a state of normal temperature, so that the denitration reactor has the advantages of small high-temperature creep deformation, high durable strength, high structural safety and low manufacturing cost.

Owner:SOUTHEAST UNIV

Vibration-reducing type engine crankcase of motorcycle

InactiveCN100476188CImprove structural strengthIncrease cooling areaCasingsMachines/enginesCrankcaseEngineering

The invention belongs to combustion engine crank box, which is a crank box for the vibration damping motorcycle engine, made up of left crank box and the right crank box, the character lies in: the left and the right crank boxes use magnesium alloy to be cast and formed, the thickness of the box wall is 3.5-6mm, several reinforcing ribs with width of 3-5mm are arranged on the box surface and the cover. Compared to the gearing aluminum alloy crank box, when the structure intensity of the box is upgraded, the heat irradiating area is also increased, it can reduce the high temperature creep, the mechanical intensity of the magnesium alloy crank box in the high temperature environment is not affected; the experience to the same motorcycle LC125 testifies, the crank box of the invention caters all the demands of engine, and the weight is reduced, thus it can save 0.4l oil per hundred kilometers, the average heat vibration and noise only the 1 / 3 of the traditional crank box.

Owner:重庆镁业科技股份有限公司

A kind of preparation method of fused barium zirconate

Owner:郑州振中电熔新材料有限公司

Method for producing high-purity electro-melting yttrium oxide sand

The invention relates to a production method for high-purity fused yttria sand, using of high-purity Y2O3 raw material with Y2O3 content no less than 99.99%as melting material. The raw material goes through the high-temperature electric arc melting no less than 2400 DEG C; the control electrode does not contact the liquid level and is no more than 2cm above the liquid level; after the high-temperature electric arc melting, the raw material forms low-carbon white transparent crystal-like frit which forms sand of particle size after being broken up. The invention adopts the electric melting method to make the white powder yttria into crystal-like product. And the method has the advantages that a long electric arc operation avoids the contact of the electrode and yttria and the introduction of carbon; the produced yttria has high purity with Y2O3content no less than 99.8%, low blowhole rate, high volume density, high temperature strength and higher degree of wear-resistance and good volume stability; the method beneficial to obtain non-polluted titanium pieces can be applied in the casting of titanium alloy and reducesthe production cost of the titanium casting, laying the foundation for the promotion of the development of the titanium casting industry; also, the method can produce yttria product with high purityto meet various application purposes.

Owner:SHANDONG LEIBAO ZIRCONIUM SCI&TECH

Composite high temperature electrical heating element and its making method

InactiveCN100536623CImprove bindingNot easy to peel offHeating element shapesHeating element materialsGraphiteUltimate tensile strength

The invention discloses a composite high-temperature electric heating element and a manufacturing method thereof. It is an electric heating element composed of three materials: graphite, silicon carbide and molybdenum disilicide; When compositing electric heating elements, graphite is used as the base layer, and the silicon carbide layer is first covered on the graphite base layer, and then the molybdenum disilicide layer is covered on the silicon carbide layer. The present invention adopts the method of high-temperature solid-phase reaction diffusion to combine graphite (or modified graphite), silicon carbide, and molybdenum disilicide layer by layer with continuous gradient changes to form an electric heating element. The continuous gradient change of , silicon carbide and molybdenum disilicide not only makes the combination of various materials good, but also makes full use of the advantages of the three electric heating materials. The invention has the advantages of low cost, small high temperature creep, high high temperature strength and is suitable for high temperature oxidizing atmosphere environment.

Owner:GUIYANG AL-MG DESIGN & RES INST

Method for making low-creepage and high-strength high temperature resisting ceramic roller

InactiveCN102249710BSmall creep at high temperatureImprove high temperature performanceMineral particlesMullite

The invention relates to a method for making a low-creepage and high-strength high temperature resisting ceramic roller. A mullite whisker in-situ reinforcement technology and a crystal boundary glass phase crystallization technology are adopted, a mineralizer containing zirconium and titanium is added to enable andalusite mineral particles in a blank to generate uniformly distributed mullite whiskers in-situ in the high-temperature reaction of kaolin with alpha-Al2O3, and thermal treatment is carried out in the cooling process to crystallize a crystal boundary liquid phase. Compared with thetraditional same type of high temperature resisting ceramic roller, the finally prepared low-creepage and high-strength high temperature resisting ceramic roller has the advantages that the high temperature strength below 1350DEG C is improved by 15-20%, and the high-temperature creepage under the condition of 1350DEG C*50hr is reduced by more than 35%.

Owner:JINGDEZHEN NUONAI TECH CERAMICS

A kind of preparation method of alumina ceramics for automobile pressure sensor

The invention discloses a preparation method of alumina ceramics for automotive pressure sensors. The preparation method comprises the following steps: A, preparing a raw material from 95-97 wt% of alpha-Al2O3, 1-2 wt% of kaolin, 0.5-2 wt% of calcium carbonate, 0.5-1 wt% of silica and 0.3-0.7 wt% of zirconium silicate, and uniformly mixing PVA17-99 and n-octyl alcohol; B, ball-milling; C, conducting spray granulation; D, dry-pressing and sintering; E, vibro-milling; and F, surface metallization. Through methods of using alumina ceramics as a matrix, adding zirconium silicate, improving ball-milling mode and conducting surface second metallization, density of the ceramic product reaches 3.69 g / cm<3> or above; elasticity modulus reaches about 310 Gpa; coefficient of thermal expansion is about 5*10<-6> / DEG C (from 25-500 DEG C); and flexural strength is about 288 Mpa.

Owner:HUNAN MEICHENG CERAMIC TECH

A kind of anhydrous micro-titanium accumulation material for blast furnace iron taphole and preparation method thereof

The invention discloses an anhydrous micro titanium stacking material used for a blast furnace taphole and a preparation method of the stacking material. The anhydrous micro titanium stacking materialis mainly prepared from the following raw materials in percentages by weight: 20-25% of compact corundum, 3-8% of kyanite, 20-25% of coke, 5-10% of Guangxi white mud, 3-8% of silicon powder, 3-8% ofsilicon carbide, 3-8% of sericite, 3-8% of silicon nitride, 3-8% of titanium silicide, and 15-20% of a composite binder. The product anhydrous micro titanium stacking material used for the blast furnace taphole prepared by utilizing the technical scheme provided by the invention has easy sintering, high strength, flushing resistance and erosion resistance; the stacking material is easy to open, and molten iron and molten slag can be guaranteed to flow out at a uniform speed; and during the use, no yellow smoke appears, the stacking material has the characteristics of protecting the environmentand saving energy, and the product performance is excellent.

Owner:义马宝宜新材料有限公司

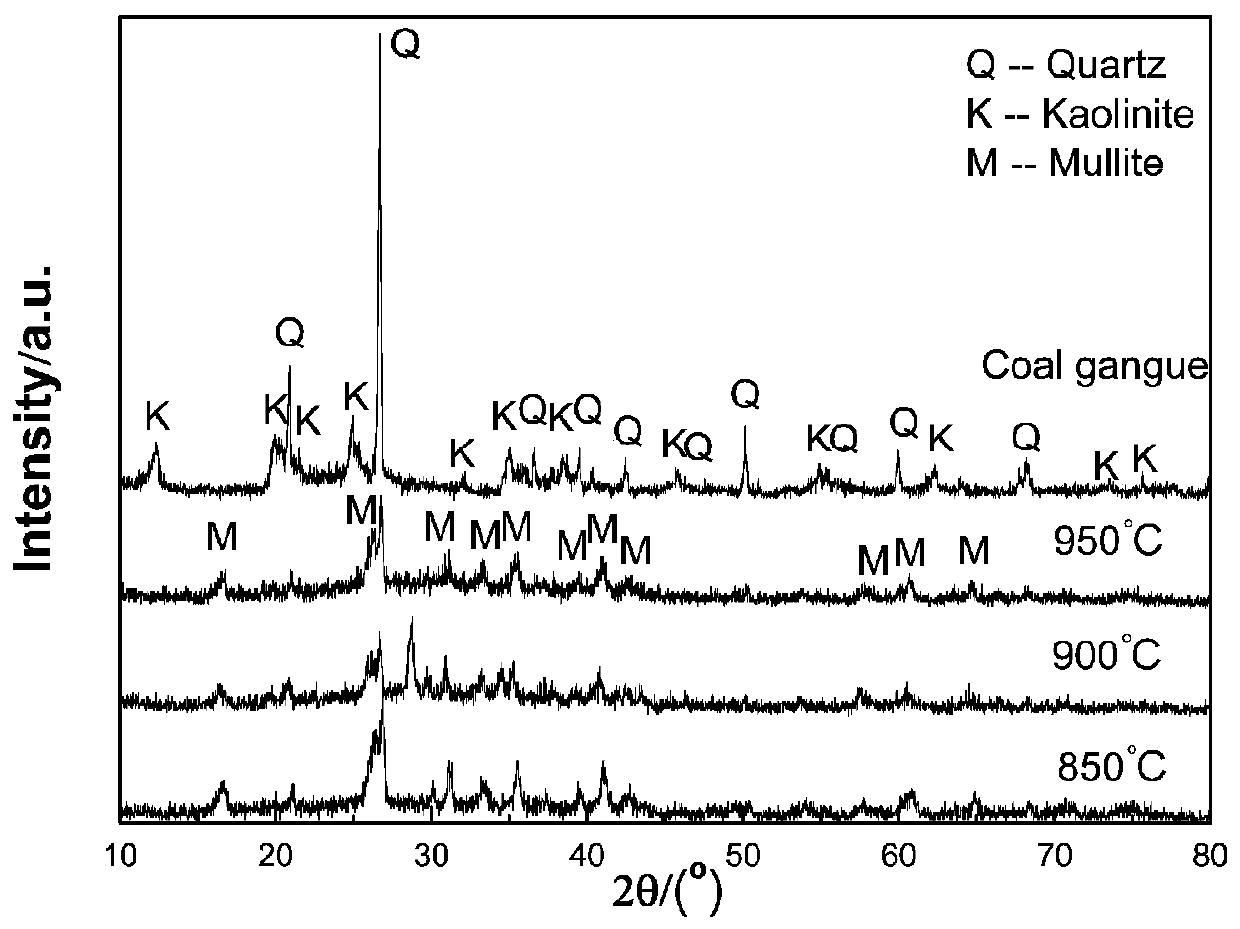

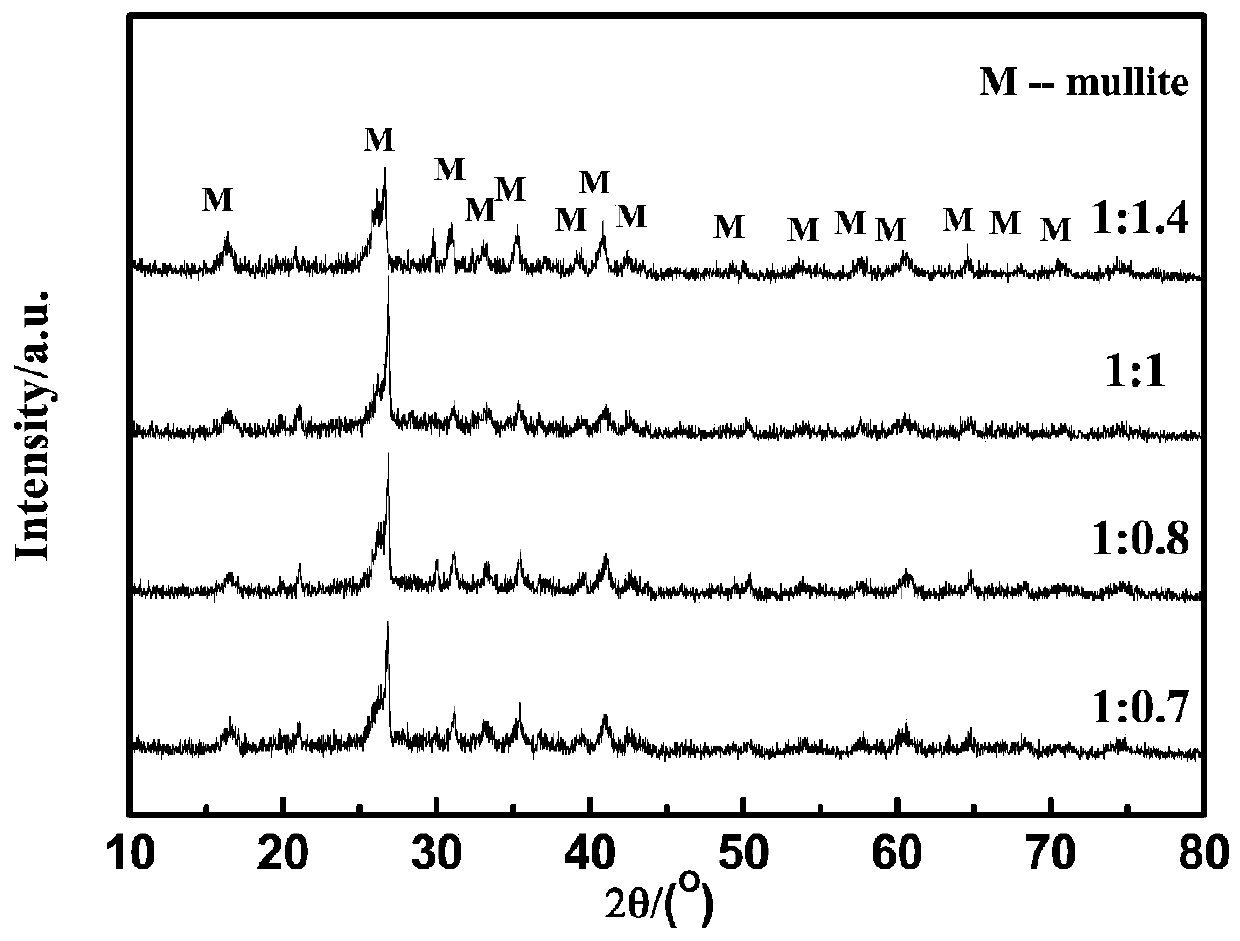

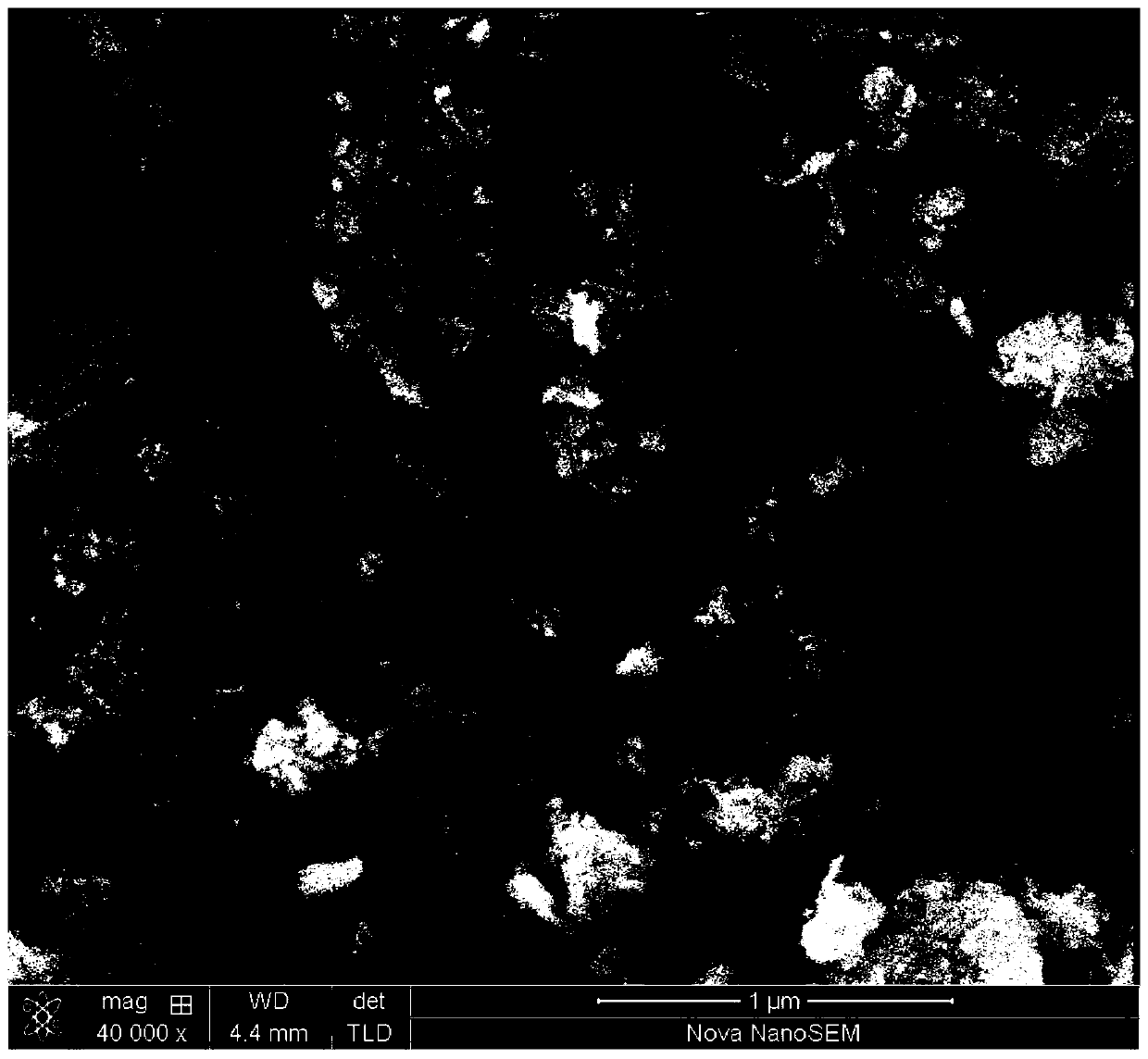

A method for synthesizing mullite powder at low temperature by molten salt method using coal gangue as raw material

The invention relates to a method for performing low-temperature synthesis on mullite powder by adopting a molten salt method taking coal gangue as raw material. The method comprises the following steps: by taking coal gangue and crystalized aluminum potassium sulfate dodecahydrate as raw materials, weighing coal gangue and aluminum potassium sulfate dodecahydrate based on stoichiometric ratio of mullite and mixing the two, placing the mixture at 750-950DEG C and calcinating for 2-5 hours, then cooling to room temperature, washing the calcinated product with deionized water, and drying to obtain the mullite powder. The aluminum potassium sulfate dodecahydrate is both reaction raw materials and molten salt, and by adopting the aluminum potassium sulfate dodecahydrate, not only can the temperature of the mullite powder synthesized by adopting solid-phase method be effectively reduced, but also the content lack of aluminum in coal gangue can be supplemented. By controlling the reaction ratio, the calcinating temperature and time of the coal gangue and the molten salt, mullite powder with different microstructure and sizes can be obtained at low temperature (750-950DEG C). Not only does the preparation process be simple, the preparation cost is low, but also the purity of the obtained product is high, and the preparation process is easy for realization of industrial production.

Owner:ANHUI UNIV OF SCI & TECH

Melting furnace structure applied to production of high aluminum electronic glass

InactiveCN110357400APrevent fallingExtended service lifeGlass furnace apparatusGlass productionBrickZircon

The invention discloses a melting furnace structure applied to production of high aluminum electronic glass. The melting furnace structure includes a melting part, the front end of which is provided with a feeding wall, both sides are provided with heat storage chambers, and the heat storage chambers and the side wall of the melting part are communicated through small furnaces; the arch top flamearea of the melting part adopts AZS fused zircon corundum brick and alpha-beta corundum brick, a non-flame area breast wall adopts alpha-beta corundum brick and beta corundum brick, the arch tops of the heat storage chambers adopt fused magnesia brick, and the pool wall and bottom of the melting part both adopt high zirconium brick. The structure can resist a high temperature of 1650DEG C, has good creep resistance, and can be melted into high aluminum glass with an aluminum content of 0-24%, and can meet the production of low iron, high aluminum, ultra white and ultra-thin (0.2-2mm) electronic glass.

Owner:XIANNING NANBO PHOTOELECTRIC GLASS CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com