Melting furnace structure applied to production of high aluminum electronic glass

A melting furnace and electronic technology, applied in glass production, glass furnace equipment, glass manufacturing equipment, etc., can solve problems such as intensified pool wall erosion, poor alkali corrosion resistance, and impact on production yield, so as to reduce the tendency of pool wall fracture, Guarantee high temperature melting and improve the effect of glass quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

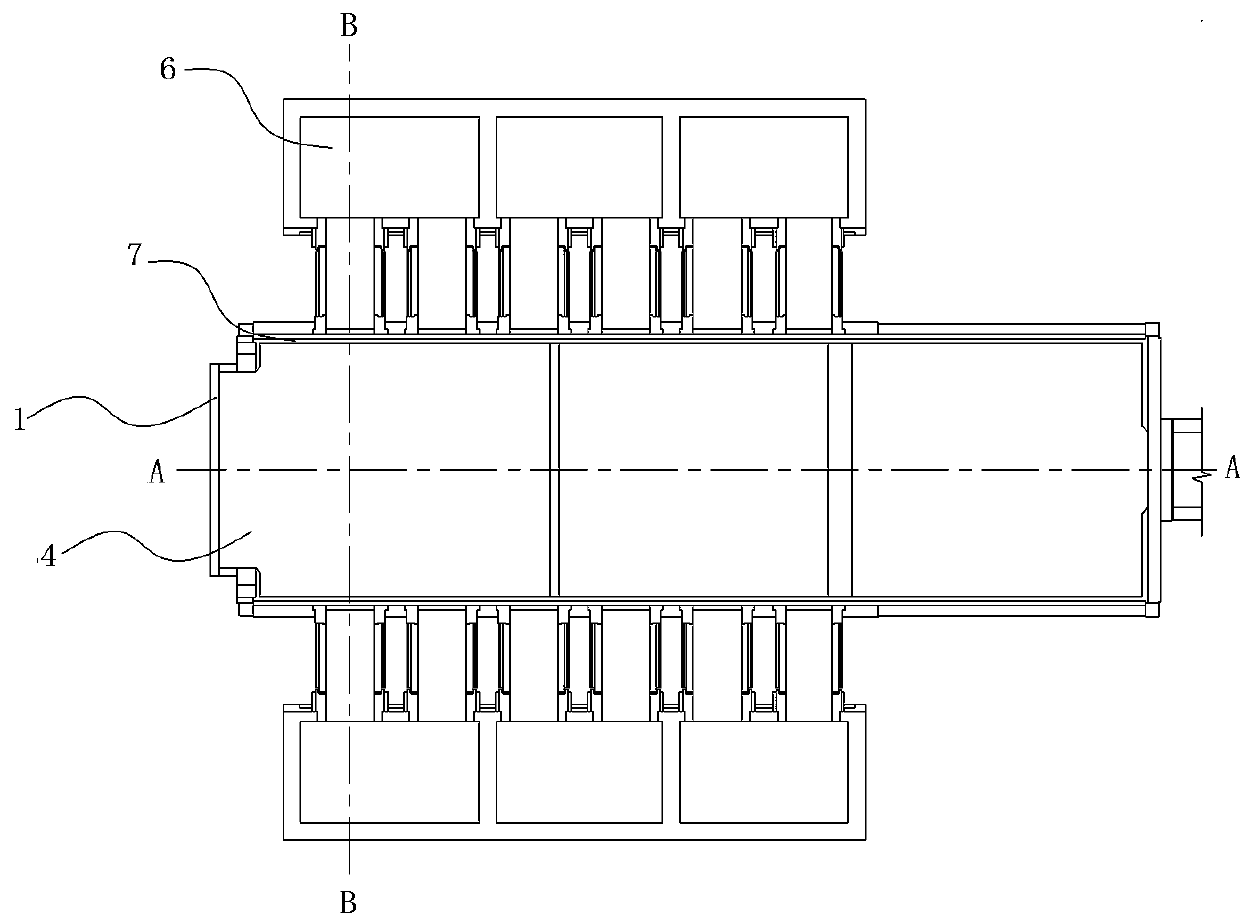

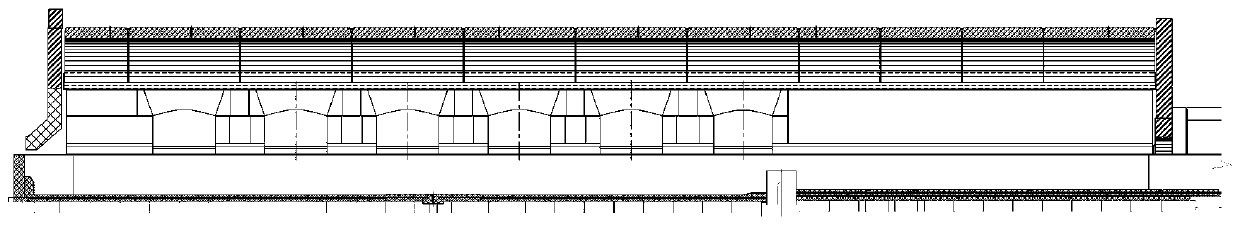

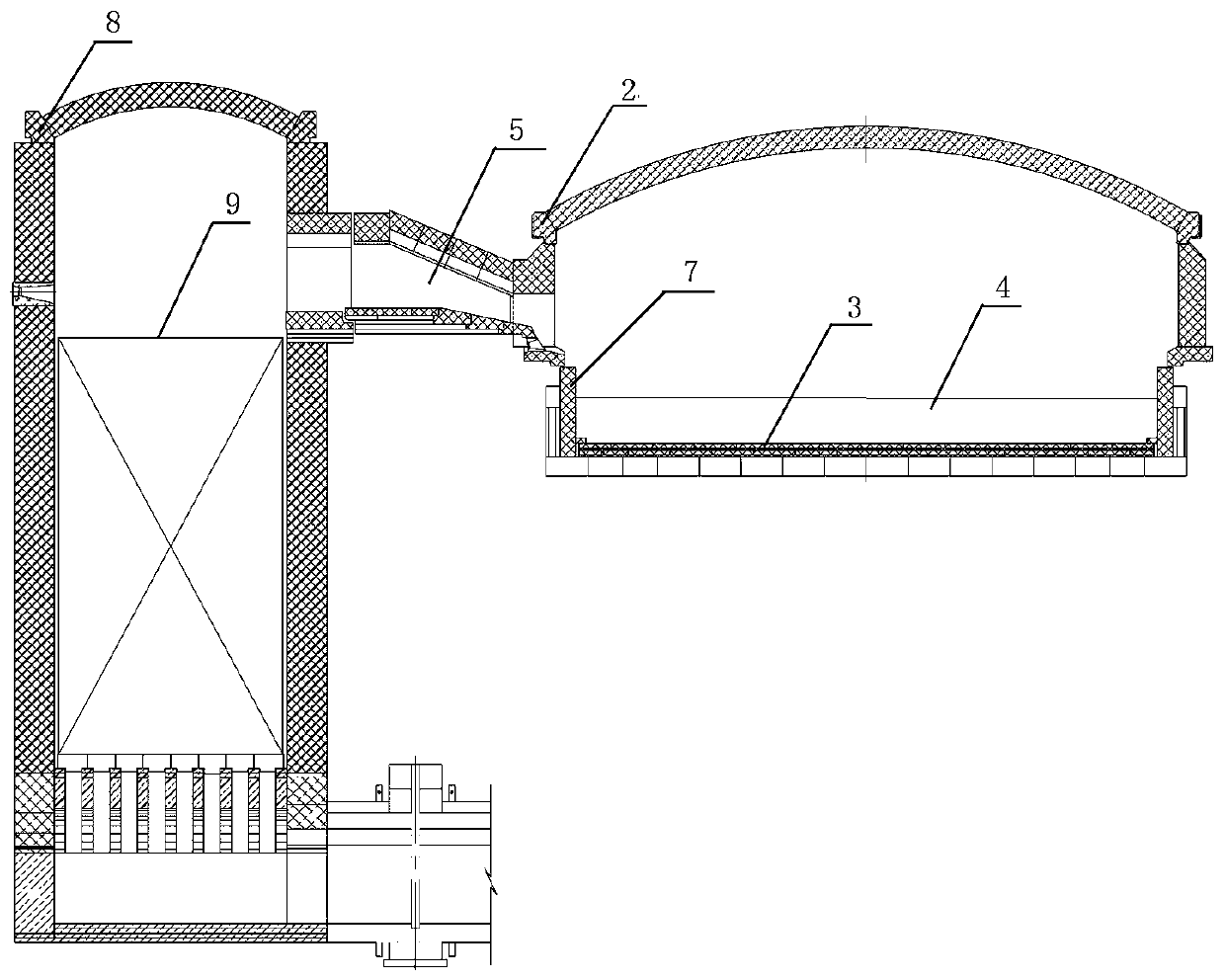

[0031] Such as Figure 1-3 As shown, the present invention relates to a melting furnace structure applied to the production of high-alumina electronic glass. The room is connected through a small furnace; AZS fused zirconia corundum bricks and α-β corundum bricks are used in the flame zone of the melting part, α-β corundum bricks and β corundum bricks are used in the breast wall of the non-flame zone, and the crest of the regenerator is electric Fused magnesia bricks, the wall and bottom of the melting part are high zirconium bricks.

[0032] Preferably, the bottom of the melting part is double-layer paving bricks, and the paving bricks are high zirconium bricks.

[0033] Preferably, protective bricks are provided on the lower side of the feeding wall located inside the melting part, and the thickness of the protective brick layer is more than 1 / 2 of the thickness of the feeding wall; the height is more than 1 / 3 of the height of the feeding wall.

[0034] Preferably, the che...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com