A method for synthesizing mullite powder at low temperature by molten salt method using coal gangue as raw material

A technology of mullite powder and coal gangue, which is applied in the field of low-temperature synthesis of mullite powder, can solve the problems of secondary environmental water pollution, unfavorable production control, and many impurities in the product, and achieve stable volume, meet the load softening point, and purity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

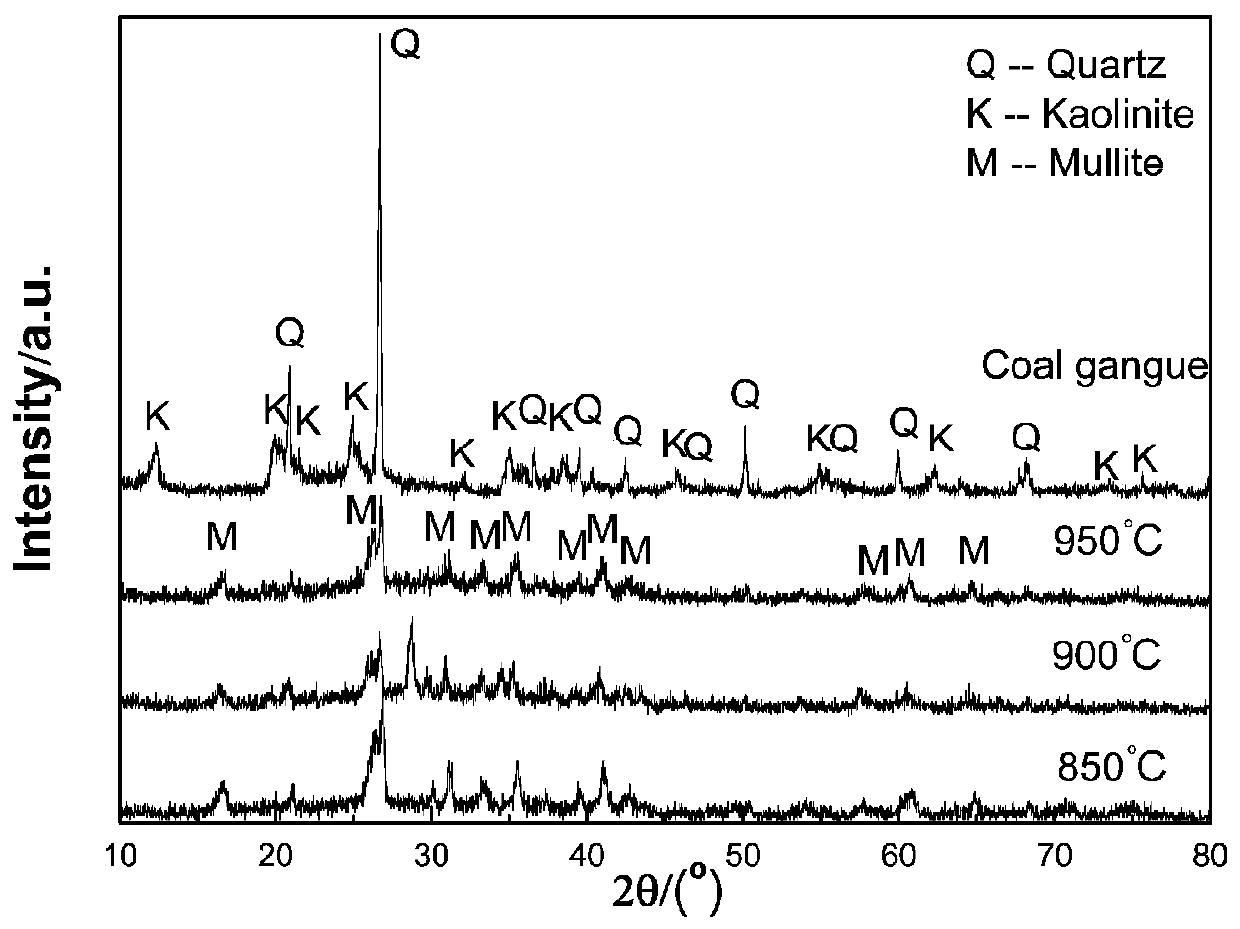

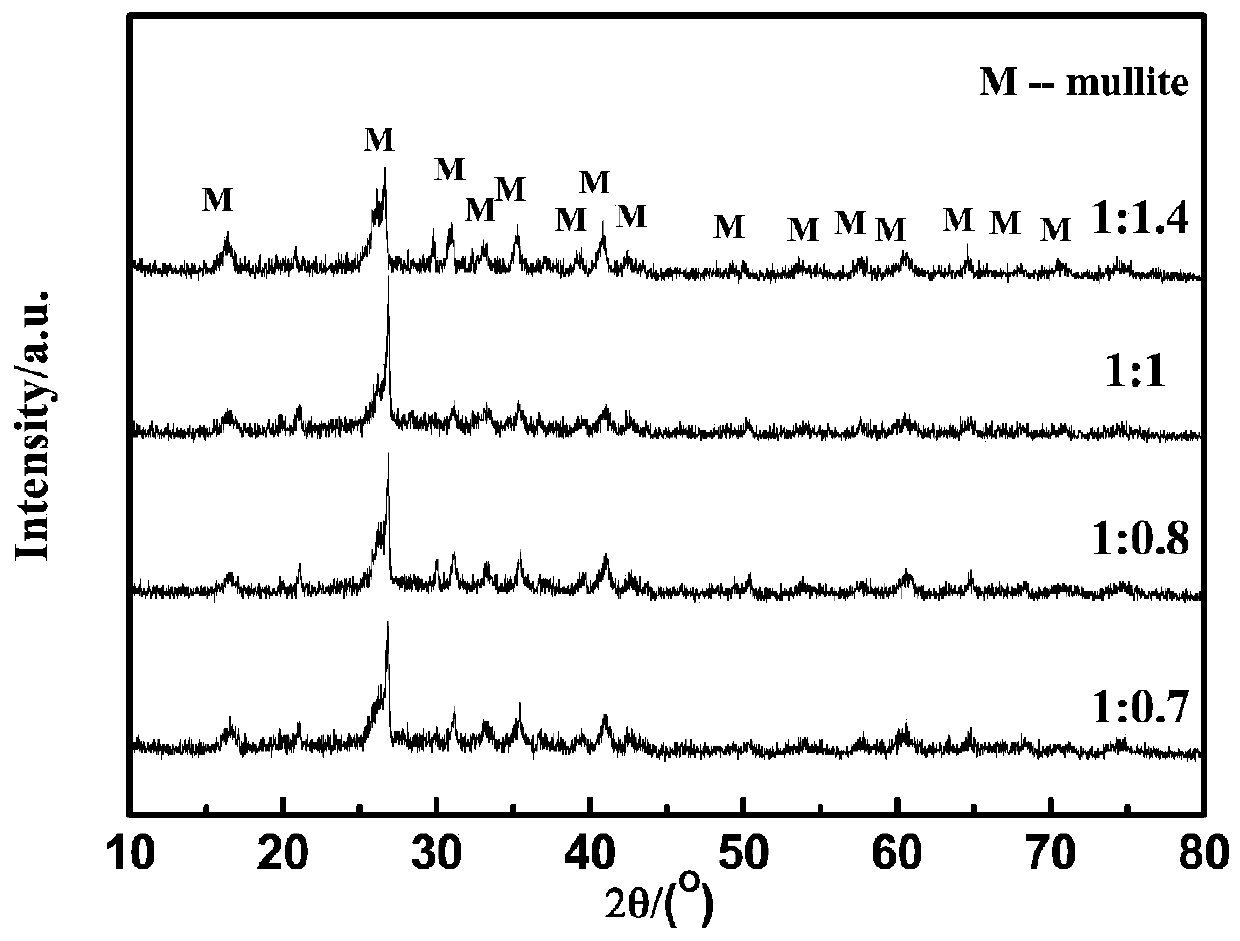

[0025] According to recipe 1: Al 2 o 3 :SiO2 2 The ratio of the molar ratio is 3:2, and the ratio of raw material crystalline potassium aluminum sulfate dodecahydrate and 200 mesh coal gangue is taken, wherein the powdered potassium aluminum sulfate dodecahydrate is used as the molten salt. Mix powdered coal gangue and crystalline potassium aluminum sulfate dodecahydrate according to the weighed ratio, then place the mixture in a box-type resistance furnace for calcination at 850°C for 3 hours, and cool to room temperature with the furnace. Finally, the calcined product is heated and dissolved with 90°C hot deionized water, put into a 90°C water bath to keep warm for precipitation, filtered, washed several times, and the obtained precipitate is dried to obtain mullite powder.

Embodiment 2

[0027] According to recipe 2: Al 2 o 3 :SiO2 2 The ratio of the molar ratio is 3:2, and the ratio of raw material crystalline potassium aluminum sulfate dodecahydrate and 200 mesh coal gangue is taken, wherein the powdered potassium aluminum sulfate dodecahydrate is used as the molten salt. After mixing powdered coal gangue and crystalline potassium aluminum sulfate dodecahydrate according to the weighed ratio, the mixture is calcined in a box-type resistance furnace at 900°C for 3 hours, and cooled to room temperature with the furnace. Finally, the calcined product is heated and dissolved with 90°C hot deionized water, put into a 90°C water bath to keep warm for precipitation, filtered, washed several times, and the obtained precipitate is dried to obtain mullite powder.

Embodiment 3

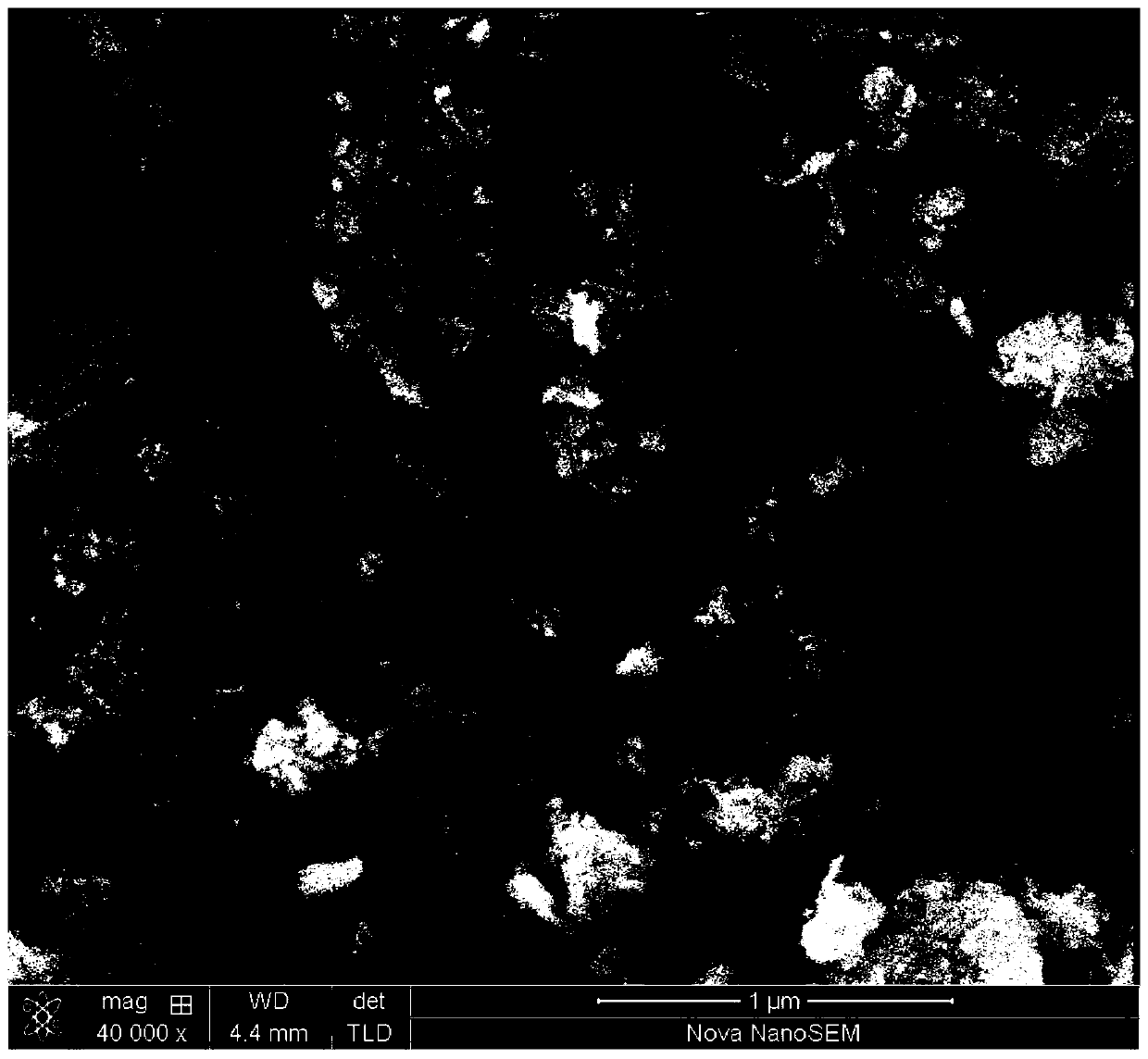

[0029] According to recipe 3: Al 2 o 3 :SiO2 2 The ratio of the molar ratio is 3:2, and the ratio of raw material crystalline potassium aluminum sulfate dodecahydrate and 200 mesh coal gangue is taken, wherein the powdered potassium aluminum sulfate dodecahydrate is used as the molten salt. After mixing powdered coal gangue and crystalline potassium aluminum sulfate dodecahydrate according to the weighed ratio, the mixture is calcined in a box-type resistance furnace at 950°C for 3 hours, and cooled to room temperature with the furnace. Finally, the calcined product is heated and dissolved with 90°C hot deionized water, put into a 90°C water bath to keep warm for precipitation, filtered, washed several times, and the obtained precipitate is dried to obtain mullite powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com