Method for preparing electrically-fused barium zirconate

A barium zirconate and electrofusion technology, applied in chemical instruments and methods, zirconium compounds, inorganic chemistry, etc., can solve the problems of low purity of barium zirconate and low purity of powder, and achieve low porosity and high bulk density. , The effect of high chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

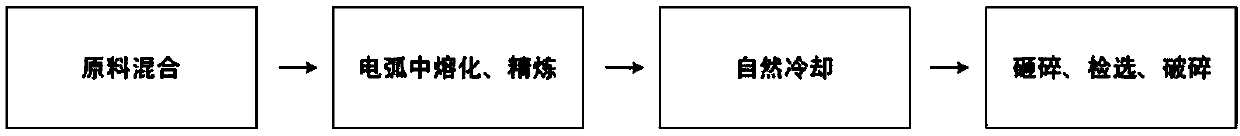

[0033] The application discloses a preparation method of fused barium zirconate, such as figure 1 shown, including the following steps:

[0034] Step 1: ZrO 2 49 parts by weight of -200 mesh natural baddeleyite with a content greater than 99%, and 51 parts by weight of barium oxide with a purity greater than 99% are put into a conical mixer, mixed evenly to make a mixed material, and the mixing time is 30 to 60 minutes ;

[0035] Step 2: Clean up the electric arc furnace, test the cooling water of each channel; connect the dense high-power graphite electrode, and the volume density of the dense high-power graphite electrode is greater than 1.78g / cm 3 , adjust the output voltage of the transformer to a gear of 154V, start the power supply; put the mixture in step 1 into the electric arc furnace for arc melting, and after the arc starting current is stable, increase the current and put in the remaining mixture to continue melting. The melting current is 5000-6000A, the meltin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com