Heating/heat insulation platform of heat former

A technology of heat insulation platform and heating platform, which is applied in the field of thermoforming machine heating/heat insulation platform, can solve the problems of high production cost, lower flatness of heating platform, unfavorable maintenance, etc., achieve convenient replacement of heating tubes, improve processing accuracy, The effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0014] The process of making the heating / insulating platform of the thermoforming machine is as follows:

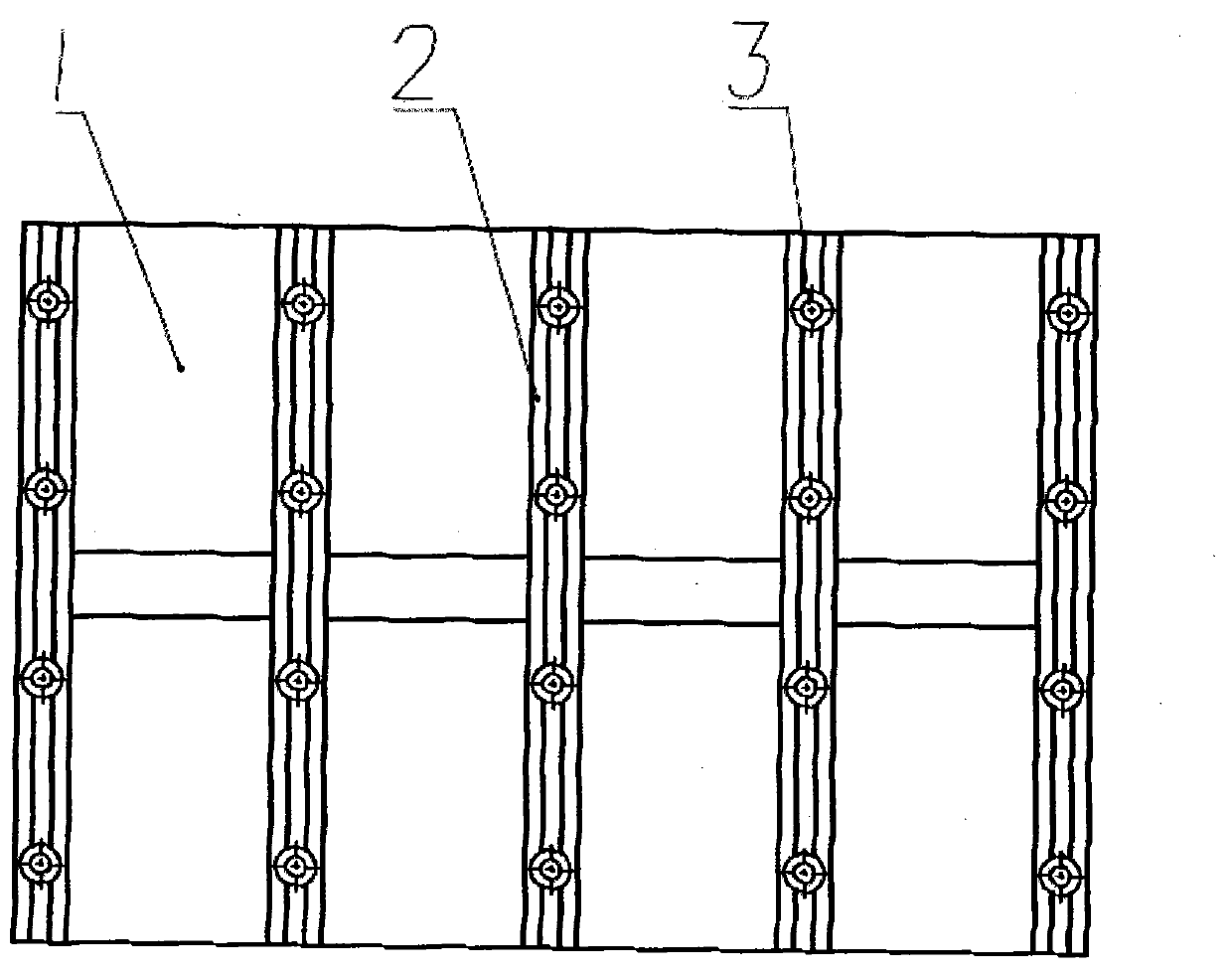

[0015] 1) Make a recrystallized silicon carbide heating platform with an appearance of 450mm×298mm×120mm, with seven Φ27mm through holes and one Φ8mm through hole.

[0016] 2) Make a corundum mullite heat insulation platform with a shape of 450mm×298mm×200mm.

[0017] 3) Grinding the upper and lower planes of the heating platform and heat insulation platform, the flatness is 0.02mm, and the parallelism is 0.05mm.

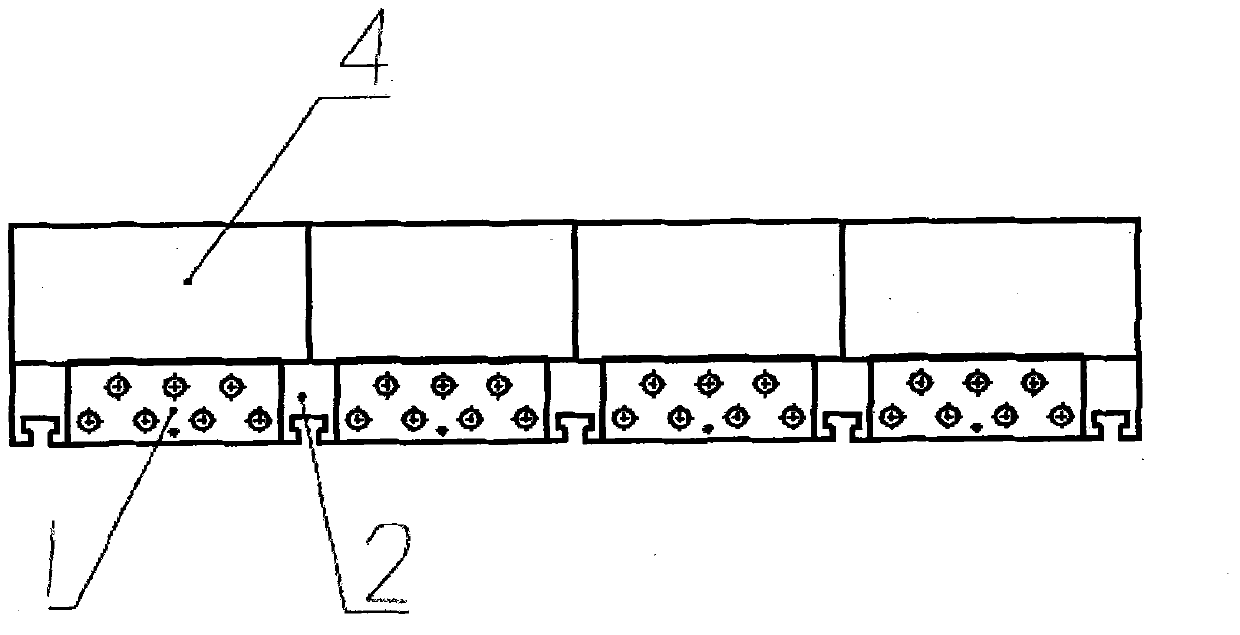

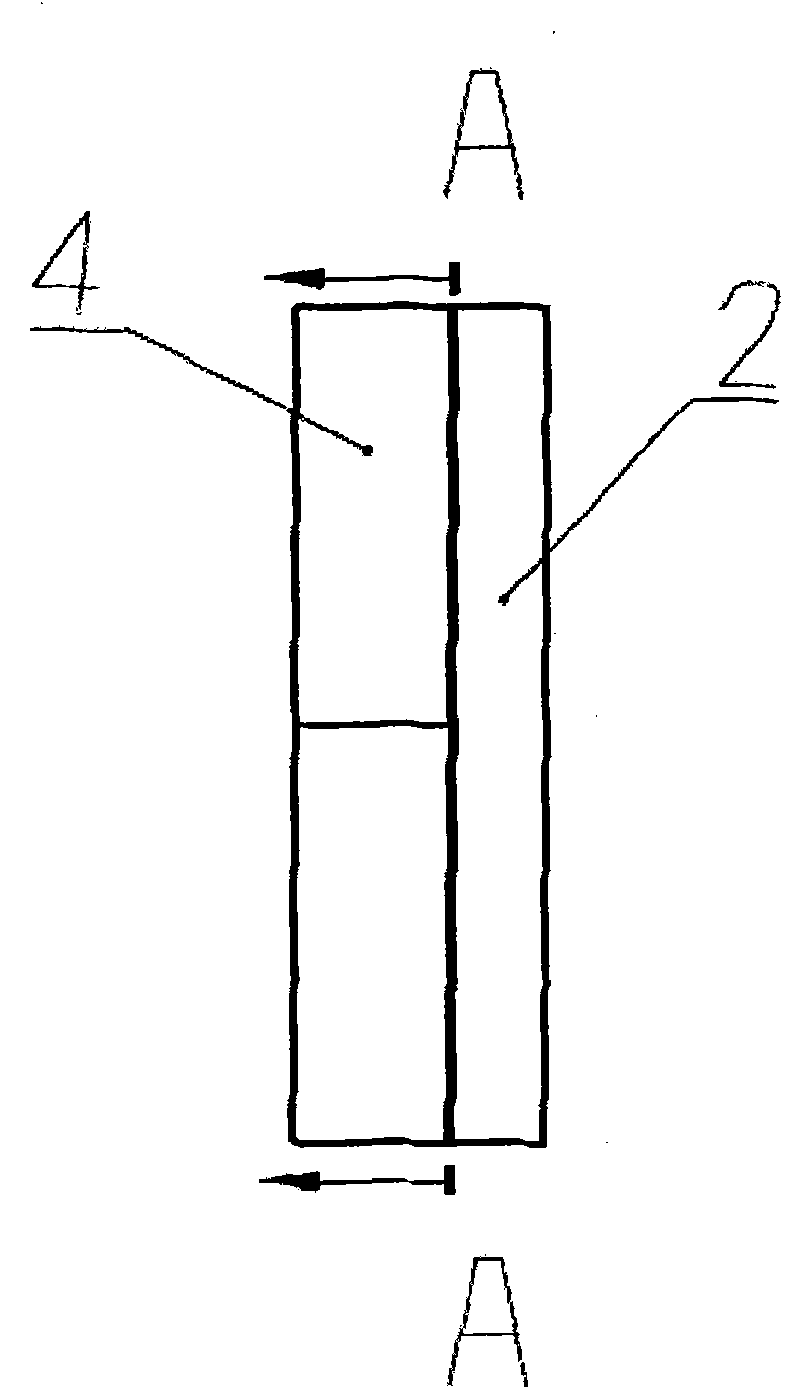

[0018] 4) High-temperature inorganic adhesive AK04-4 mixes A and B components in a ratio of 3:2, and applies it on the surface with a thickness of 3 mm. Figure 4 The area shown; apply the high temperature adhesive LYHG-23 to a thickness of 3mm Figure 4 Bond the heated and insulated platforms together in the areas shown.

[0019] 5) Use high-temperature pressurization equipment to apply a uniform pressure of 5 MPa on the upper and lower surfaces of the heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com