Composite high temperature electrical heating element and its making method

A production method and electric heating technology, applied in the direction of electrical components, heating element materials, heating element shapes, etc., can solve the problem that the use effect of electric heating elements is not ideal, the weight of heating elements is elongated and thin, and the oxidation of electric heating elements is intensified, etc. problem, to achieve the effect of low cost, small creep at high temperature, and not easy to peel off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

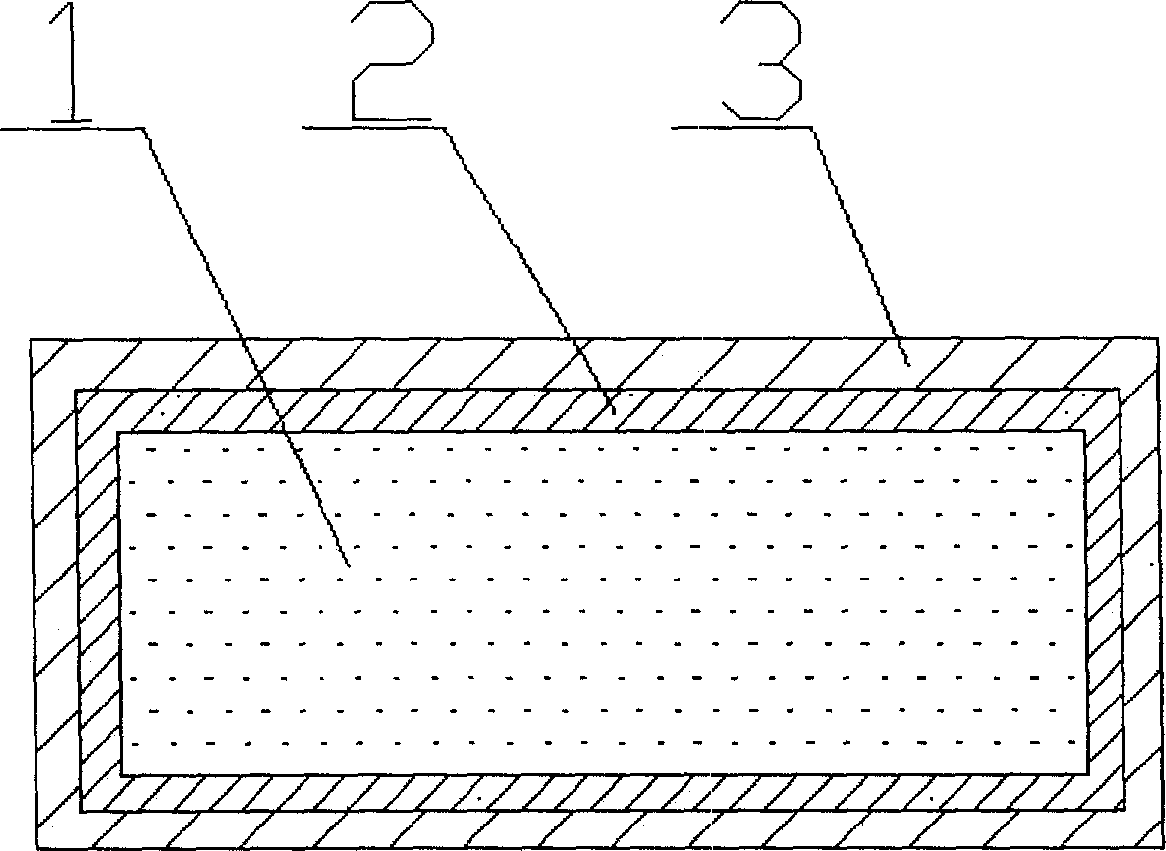

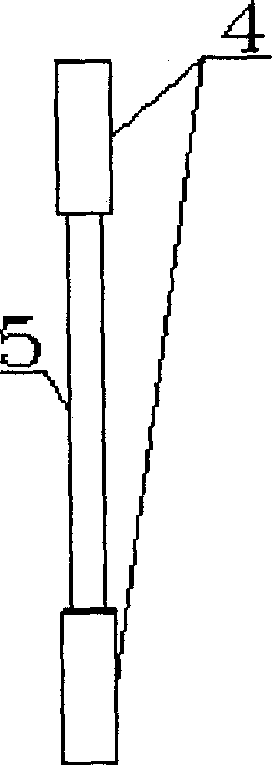

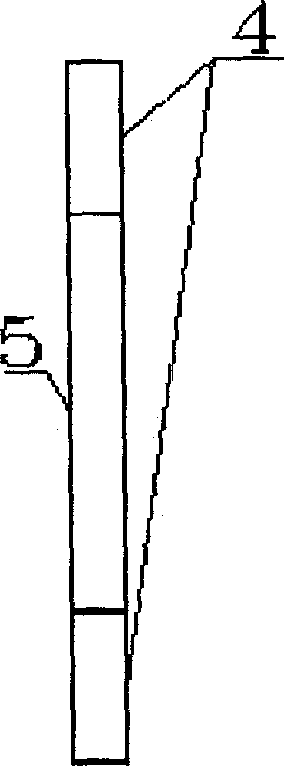

[0016] Embodiment 1 of the present invention: when graphite (or modified graphite), silicon carbide and molybdenum disilicide are combined to form an electric heating element, graphite (or modified graphite) is used as the base layer, and the shape of the base layer It can be made into a cylindrical rod shape, a straight rectangular shape, a ring shape or a plate shape, and its size can be determined according to the needs of use, and then a layer of silicon carbide with a thickness of 1 to 5 mm is covered on the base layer of graphite (or modified graphite) layer, the graphite base layer covered with the silicon carbide layer is first sintered at a temperature of 1300°C to 1600°C for 0.5 to 2 hours, and then the silicon carbide layer is covered with a layer of molybdenum disilicide layer with a thickness of 1 to 5 mm, and then Sinter them together at a temperature of 1800°C to 2000°C for 0.5 to 2 hours. When the silicon carbide layer is covered on the graphite base layer and ...

Embodiment 2

[0017] Embodiment 2 of the present invention: when graphite (or modified graphite), silicon carbide and molybdenum disilicide are combined to form an electric heating element, graphite (or modified graphite) is used as the base layer, and the shape of the base layer can be adjusted. It can be made into a cylindrical rod shape, a straight rectangle, a ring or a plate shape, and its size can be determined according to the needs of the use. When covering the silicon carbide layer on the graphite (or modified graphite) base layer, the graphite (or modified graphite) Graphite) base layer is heated to 1400-1600 ° C, and then the heated graphite base layer is contacted with silicon-containing gas to react, so that a layer of 1-2 mm thick silicon carbide layer can be produced on the graphite base layer, and then use Molybdenum disilicide powder of 300 mesh or more is sprayed and covered on the silicon carbide layer to form a layer of molybdenum disilicide layer with a thickness of 1 to...

Embodiment 3

[0018] Embodiment 3 of the present invention: when graphite (or modified graphite), silicon carbide and molybdenum disilicide are combined to form an electric heating element, graphite (or modified graphite) is used as the base layer, and the shape of the base layer can be adjusted. It can be made into a cylindrical rod shape, a straight rectangular shape, a ring shape or a plate shape, and its size can be determined according to the needs of the use. Cover the graphite (or modified graphite) base layer with silicon carbide powder of 300 mesh or more A layer of 1-5 mm thick silicon carbide layer, and then cover the silicon carbide layer with a layer of 1-5 mm thick molybdenum disilicide layer made of molybdenum disilicide powder with a thickness of 300 mesh or more. After pressure molding, it is then sintered at a temperature of 1800°C to 2000°C for 0.5 to 2 hours.

[0019] When using the present invention, first the composite electric heating element of the present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com