Sliding brick with carbon nanotube combined with ferrosilicon nitride and preparation method thereof

A carbon nanotube and ferrosilicon nitride technology, applied in the field of refractory materials, can solve the problems of reduced thermal shock resistance and erosion resistance, difficult to meet the continuous casting of clean steel, affecting the cleanliness of molten steel, etc., so as to improve the erosion resistance. , Excellent thermal shock resistance and erosion resistance, the effect of reducing the amount of carbon dissolved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1 A sliding brick made of carbon nanotubes combined with ferrosilicon nitride, the raw material composition of the sliding brick is: 55% tabular alumina, 25% white corundum, 4% alumina powder (Model CL370), 15% ferrosilicon nitride, 1% carbon nanotubes, plus PF5323 phenolic resin is 2% of the total composition of the above skateboard brick raw materials.

[0039] Among them, the particle size of ferrosilicon nitride is 320 mesh, and the particle size of carbon nanotube is 490 mesh.

[0040] The tabular alumina includes three different particle sizes: 8 mesh ≤ particle size 1 ≤ 14 mesh, 14 mesh < particle size 2 < 28 mesh, 28 mesh ≤ particle size 3 ≤ 48 mesh, and the weight ratio between them is particle size 1: particle size 2: Granularity 3=3.4:2.4:1.4.

[0041] The white corundum includes two different grain sizes: 0

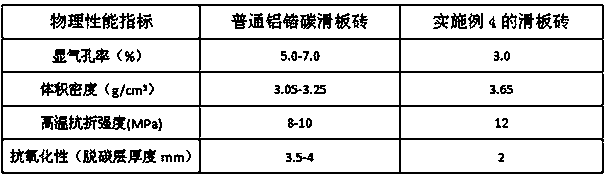

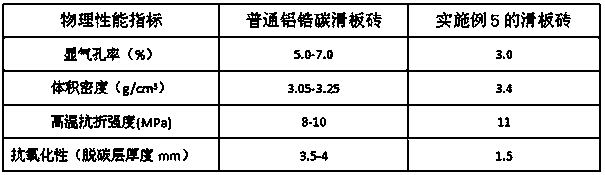

Embodiment 2

[0055] Example 2 A sliding brick made of carbon nanotubes combined with ferrosilicon nitride, the raw material composition of the sliding brick is: 57% tabular alumina, 18% white corundum, 4% alumina powder (Model CL370), 20% ferrosilicon nitride, 1% carbon nanotubes, plus PF5323 type phenolic resin is 3% of the total composition of the above skateboard brick raw materials.

[0056] Among them, the particle size of ferrosilicon nitride is 325 mesh, and the particle size of carbon nanotube is 500 mesh.

[0057] The tabular alumina includes three different particle sizes: 8 mesh ≤ particle size 1 ≤ 14 mesh, 14 mesh < particle size 2 < 28 mesh, 28 mesh ≤ particle size 3 ≤ 48 mesh, and the weight ratio between them is particle size 1: particle size 2: Granularity 3=3:2:1.

[0058] The white corundum includes two different grain sizes: 0

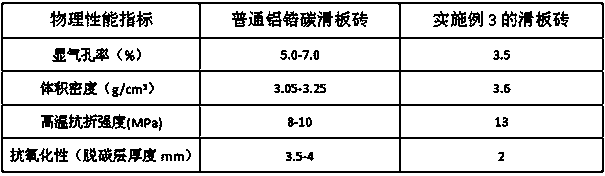

Embodiment 3

[0062] Example 3 A sliding brick made of carbon nanotubes combined with ferrosilicon nitride, the raw material composition of the sliding brick is: 60% tabular alumina, 15% white corundum, 4% alumina powder (Model CL370), 20% ferrosilicon nitride, 1% carbon nanotubes, plus PF5323 phenolic resin is 5% of the total composition of the above skateboard brick raw materials.

[0063] Among them, the particle size of ferrosilicon nitride is 330 mesh, and the particle size of carbon nanotube is 510 mesh.

[0064] The tabular alumina includes three different particle sizes: 8 mesh ≤ particle size 1 ≤ 14 mesh, 14 mesh < particle size 2 < 28 mesh, 28 mesh ≤ particle size 3 ≤ 48 mesh, and the weight ratio between them is particle size 1: particle size 2: Granularity 3=2.6:1.6:0.6.

[0065] The white corundum includes two different grain sizes: 0

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com