Complex molded surface pneumatic loading superplastic forming diffusion bonding method

A technology of superplastic forming and diffusion bonding, which is applied in the field of sheet metal thermal processing, and can solve problems such as reducing the frequency of mold rework and insufficient welding rate of diffusion bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

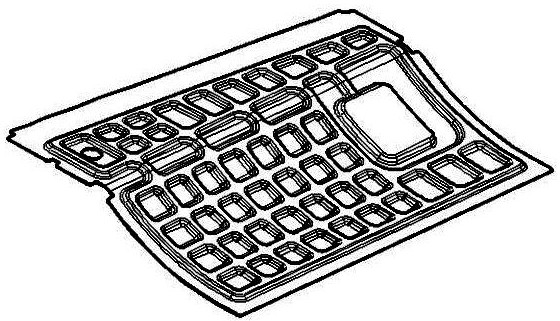

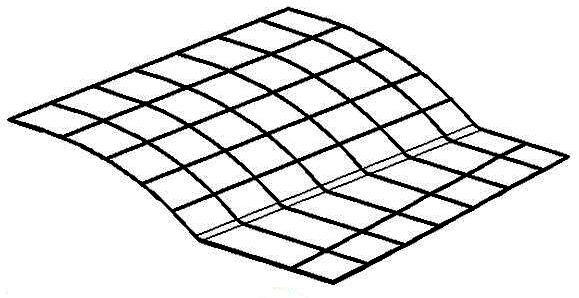

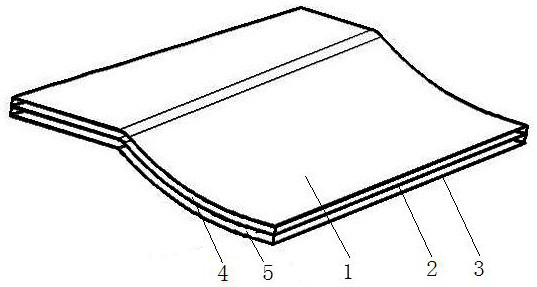

[0051] see Figure 1-Figure 3 , a complex surface pneumatically loaded superplastic forming diffusion connection method, comprising the following steps:

[0052] a. First use the concave and convex die of the titanium alloy thermoforming mold to preform the upper panel, lower panel and auxiliary plate of the part, so that the preformed sheet material diffusion area profile is consistent with the part profile;

[0053] b. Drill two positioning holes according to the surface of the preformed part, and draw the outline line of the diffusion and handover area according to the solder resist spraying sample based on the positioning hole;

[0054] c. Carve criss-cross ventilation grooves on the auxiliary plate according to the contour line of the diffusion junction area, so that the position of each ventilation groove passes through the diffusion connection area;

[0055] d. The gas path is carved by a five-axis laser cutting machine;

[0056] e. Pickling and degreasing the preform...

Embodiment 2

[0064] see Figure 1-Figure 3 , a complex surface pneumatically loaded superplastic forming diffusion connection method, comprising the following steps:

[0065] a. First use the concave and convex die of the titanium alloy thermoforming mold to preform the upper panel, lower panel and auxiliary plate of the part, so that the preformed sheet material diffusion area profile is consistent with the part profile;

[0066] b. Drill two positioning holes according to the surface of the preformed part, and draw the outline line of the diffusion and handover area according to the solder resist spraying sample based on the positioning hole;

[0067] c. Carve criss-cross ventilation grooves on the auxiliary plate according to the contour line of the diffusion junction area, so that the position of each ventilation groove passes through the diffusion connection area;

[0068] d. The gas path is carved by a five-axis laser cutting machine;

[0069] e. Pickling and degreasing the preform...

Embodiment 3

[0080] see Figure 1-Figure 3 , a complex surface pneumatically loaded superplastic forming diffusion connection method, comprising the following steps:

[0081] a. First use the concave and convex die of the titanium alloy thermoforming mold to preform the upper panel, lower panel and auxiliary plate of the part, so that the preformed sheet material diffusion area profile is consistent with the part profile;

[0082] b. Drill two positioning holes according to the surface of the preformed part, and draw the outline line of the diffusion and handover area according to the solder resist spraying sample based on the positioning hole;

[0083] c. Carve criss-cross ventilation grooves on the auxiliary plate according to the contour line of the diffusion junction area, so that the position of each ventilation groove passes through the diffusion connection area;

[0084] d. The gas path is carved by a five-axis laser cutting machine;

[0085] e. Pickling and degreasing the preform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com