A Method for Realizing Nanoscale Overlay Accuracy by Microscopy

An overlay precision and microscope technology, which is applied in the direction of microlithography exposure equipment, photoplate making process exposure device, etc., can solve the problems that affect the final product yield, low accuracy of human eye recognition, large error, etc., and achieve the reduction of online overlay. The effect of accuracy failure rate, reduction of rework frequency, and improvement of detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to illustrate the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

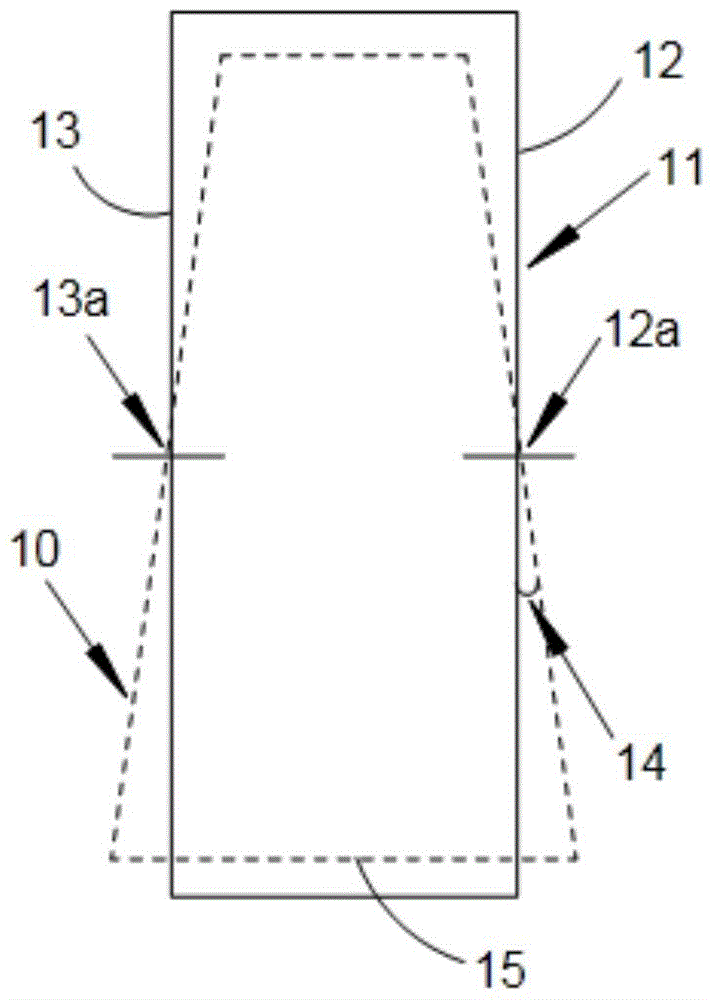

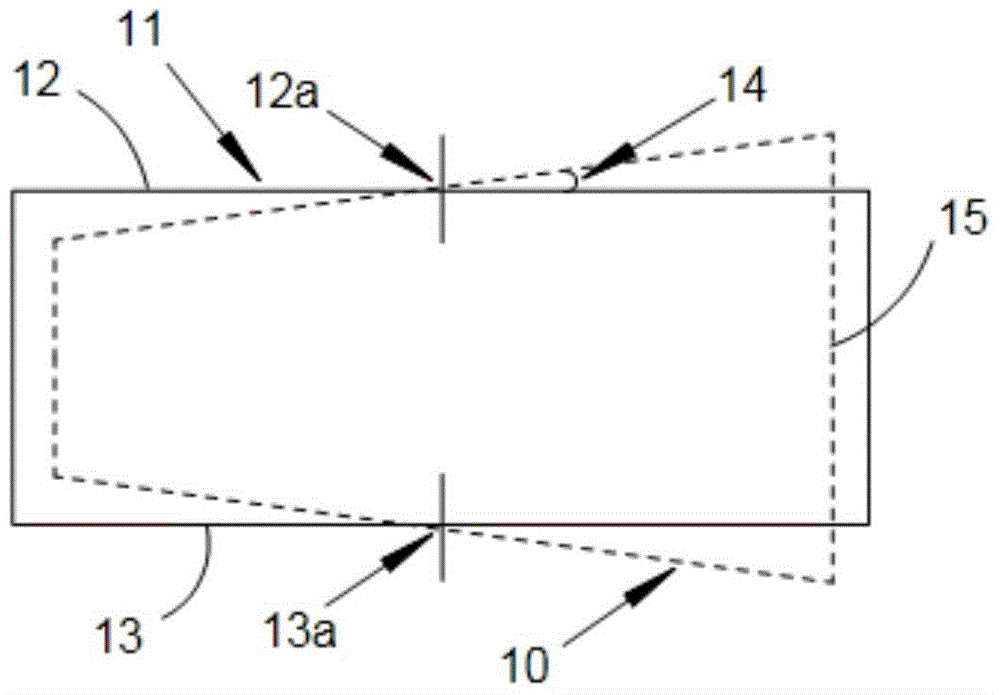

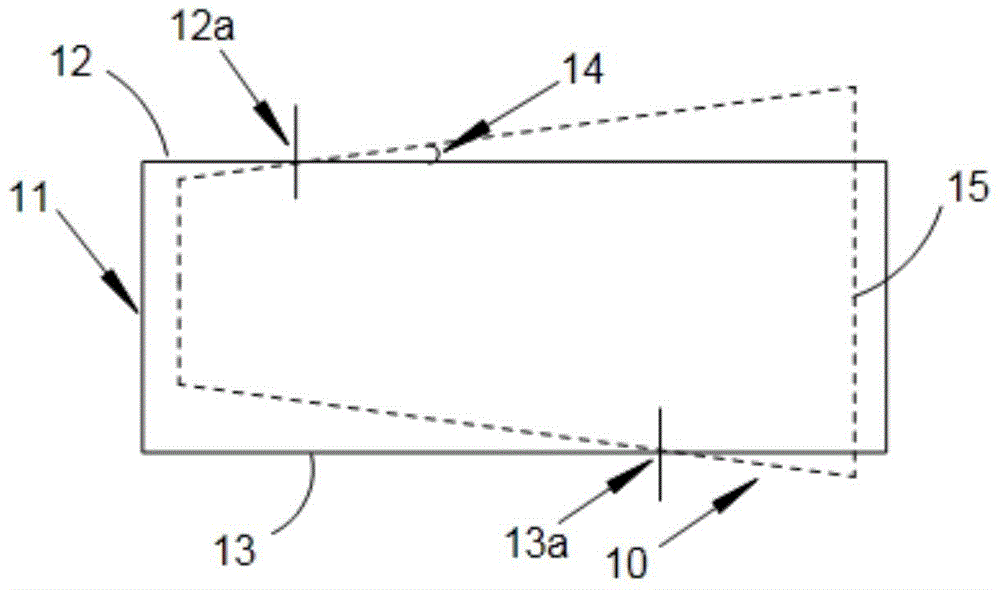

[0024] see figure 1 , figure 1 Shown is a schematic diagram of the principle of the method for realizing nanoscale overlay precision through microscopy in the present invention. The method for realizing nanoscale overlay precision by microscopy includes:

[0025] Execute step S1: provide a mask plate (not shown) with the current layer pattern 10, when the overlay accuracy of the current layer pattern 10 of the mask plate and the defined previous layer pattern 11 is zero, the current layer pattern 10 and the front layer pattern 11 have a first intersection point 12a and a second intersection point 13a on the first boundary 12 and the second boundary 13 that are set opposite to each other in the first direction, and the first intersectio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com