Reducing vibration type engine crankcase of motorcycle

A technology for crankcases and motorcycles, used in engine components, machines/engines, mechanical equipment, etc., can solve problems such as low tensile strength, improve structural strength, reduce high temperature creep, and increase heat dissipation area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

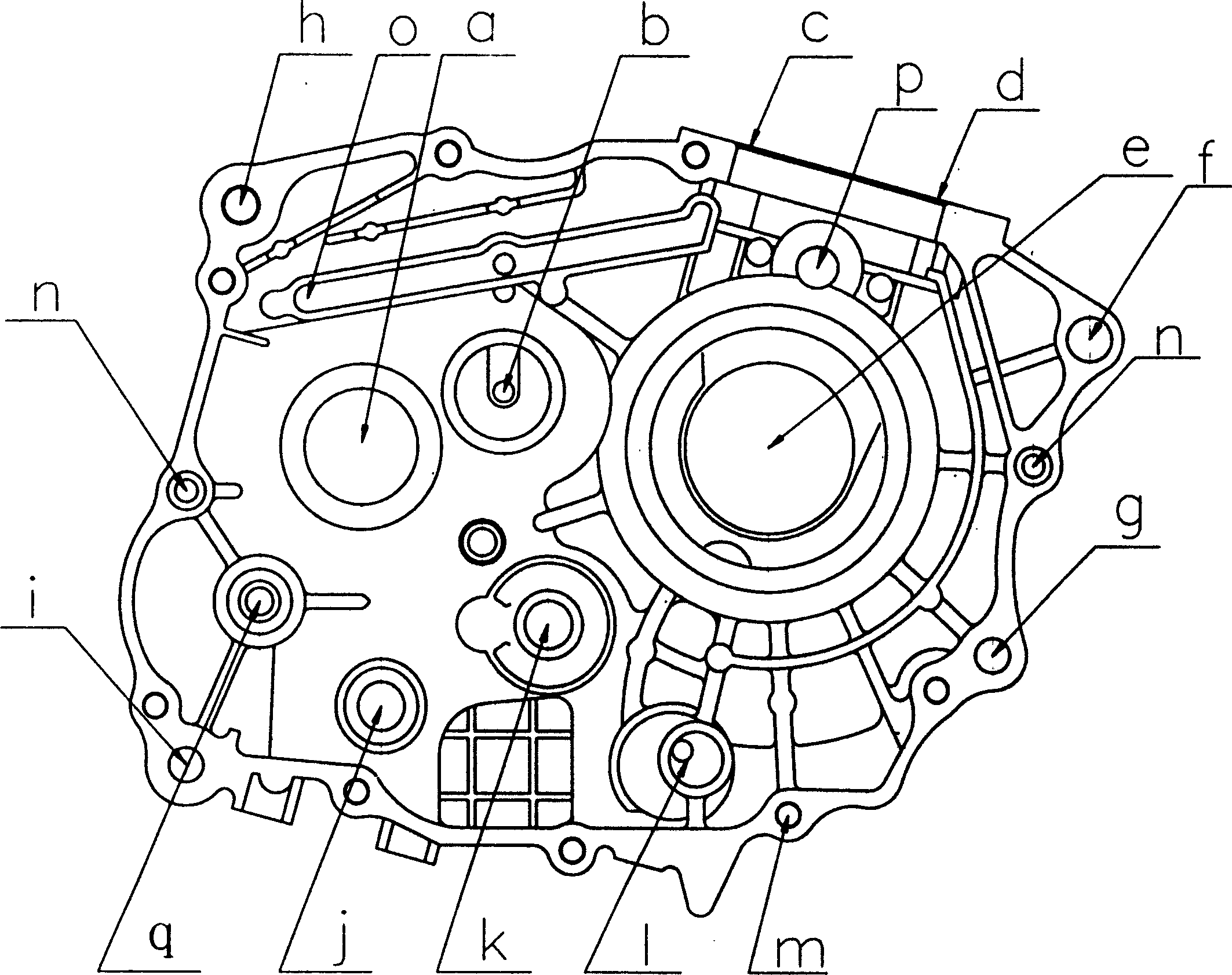

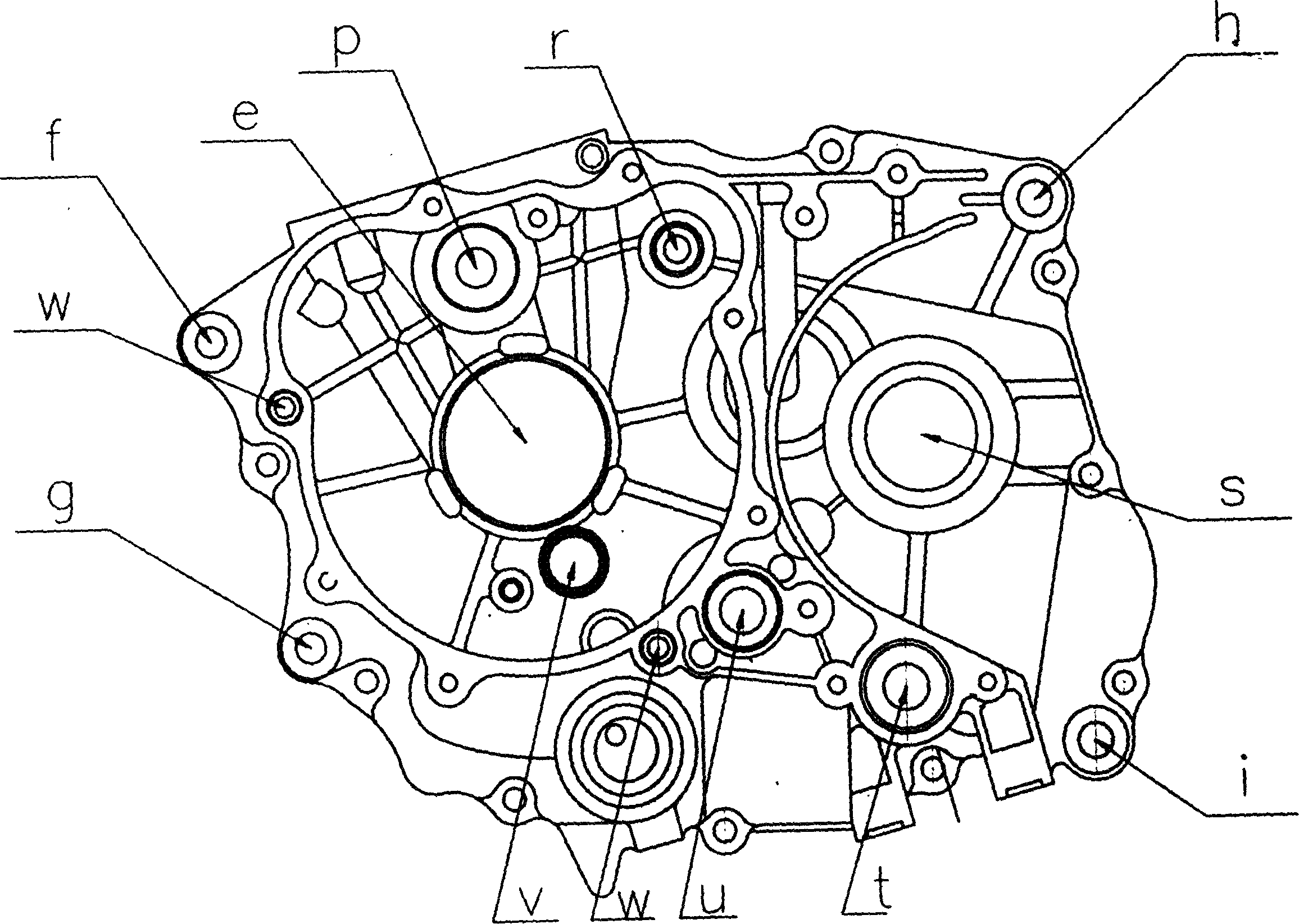

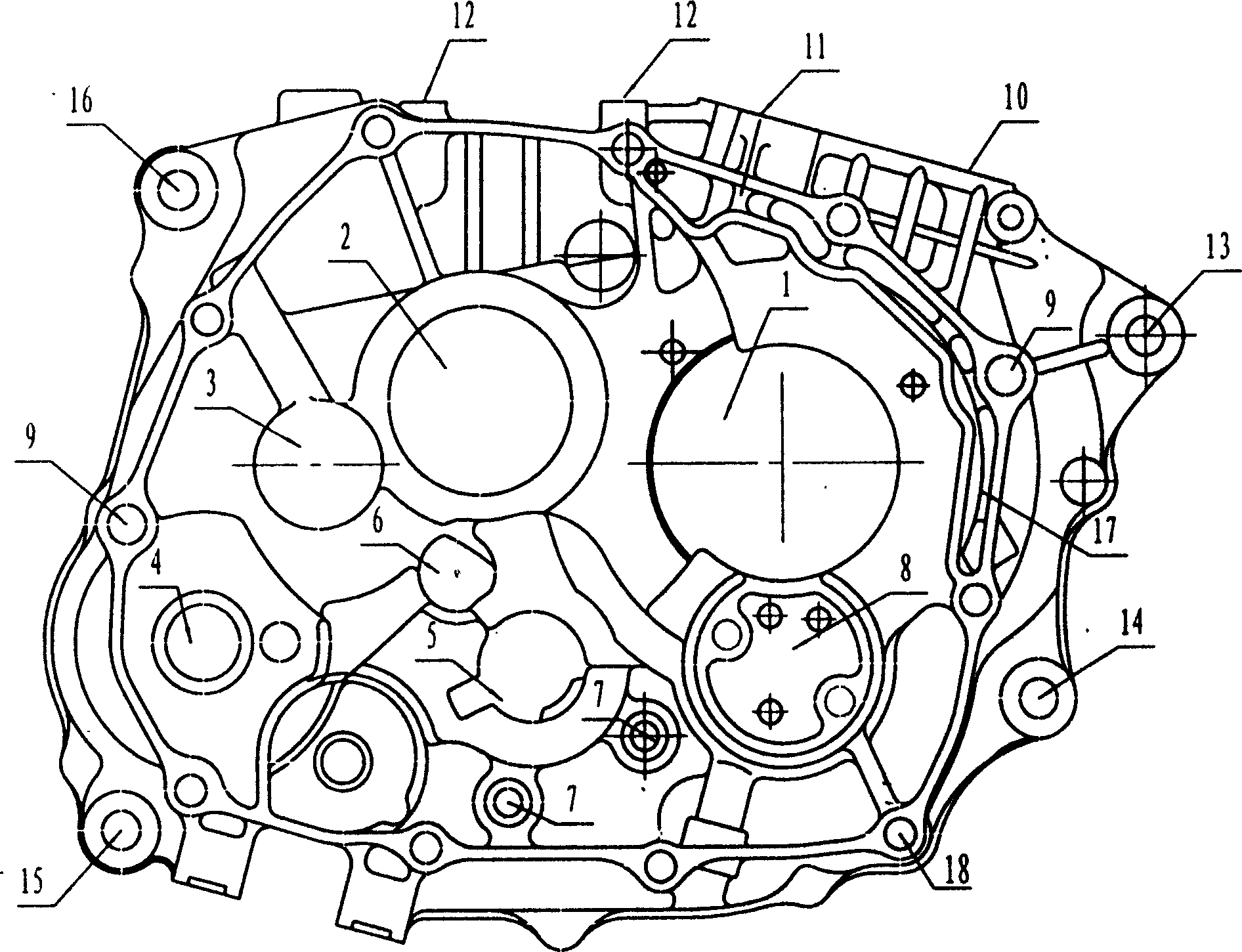

[0016] Taking the shock-absorbing motorcycle engine crankcase of the present invention which is die-cast with AZ91D magnesium alloy for LC150 / 125 models as an example, the improved structure of the present invention will be described in detail in conjunction with the accompanying drawings.

[0017] On the closing surface of the left crankcase (see figure 1 ), one 4mm wide reinforcing rib is provided near the A bolt hole (c) and the B bolt hole (d), and one 5mm wide rib is provided between the front suspension hole 1(f) and the crankshaft hole (e) There is a 5mm wide reinforcing rib at the front suspension hole 2(g), between the starting shaft hole (q) and the positioning pin hole (n) on the closing surface and the rear suspension hole 2(i) Each is provided with a 4.5mm wide reinforcing rib.

[0018] On the cover surface of the left crankcase (see figure 2 ), the wall thickness of the box within the radius of 100mm around the crankshaft hole (e) is 5mm, the wall thickness of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com