A kind of rare earth metal salt ceramic composite coating and its preparation method and application

A ceramic composite, rare earth metal technology, applied in metal material coating process, coating, discharge tube and other directions, can solve the problems of limited plasma etching resistance and low service life, and achieve no birefringence effect, long service life, The effect of homogeneous structure and composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

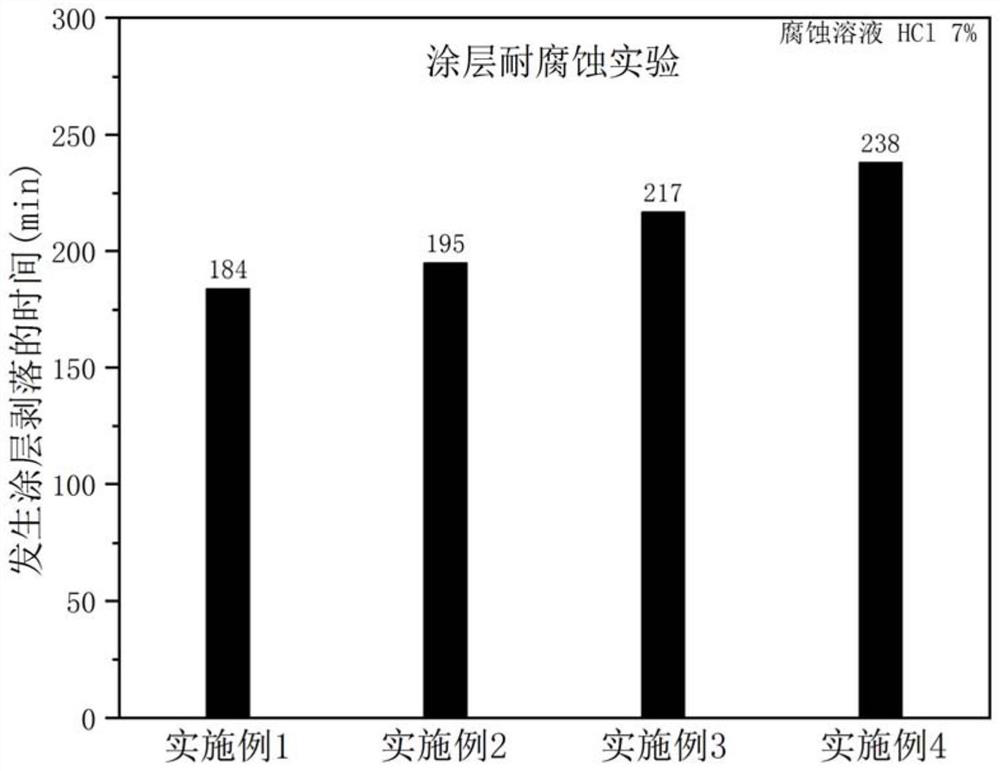

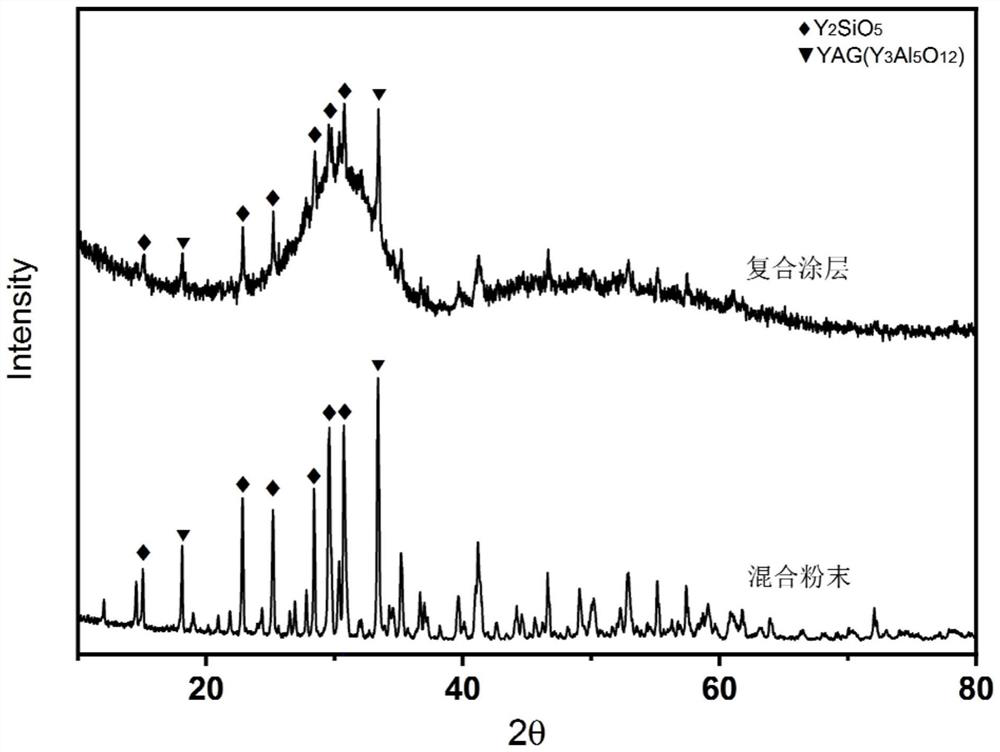

Embodiment 1

[0032] The aluminum substrate was cleaned and dried, and then the surface of the substrate was sandblasted under the conditions of a sandblasting pressure of 0.2Mpa and a sandblasting height of 400mm to obtain a substrate with a surface roughness Ra of 4μm. The sandblasted substrate is sprayed. Take Y with a particle size of 300-600nm in a mass ratio of 60:15:25 2 O 3 , Al 2 O 3 and SiO 2 powder, mixed and calcined at 1500°C for 2 hours to obtain Y 2 SiO 5 and Y 3 Al 5 O 12 of the mixed powder, prepared in the mixed powder of Y 2 SiO 5 and Y 3 Al 5 O 12 The particle size is 15-65μm. Argon and helium are used as plasma gases, argon is the main gas, and helium is the secondary gas. The flow rate of argon gas is 60L / min, the flow rate of helium gas is 20L / min, and the voltage is 30V and the current is 800A. Under the condition of powder feeding speed of 40g / min, plasma spray was carried out at a distance of 120mm from the surface of the substrate to obtain a compos...

Embodiment 2

[0034] The aluminum substrate was cleaned and dried, and then the surface of the substrate was sandblasted under the conditions of a sandblasting pressure of 0.3Mpa and a sandblasting height of 400mm to obtain a substrate with a surface roughness Ra of 6μm. The sandblasted substrate is sprayed. Take Y with a particle size of 300-600nm in a mass ratio of 65:15:20 2 O 3 , Al 2 O 3 and SiO 2 powder, mixed and calcined at 1500°C for 2 hours to obtain Y 2 SiO 5 and Y 3 Al 5 O 12 of the mixed powder, prepared in the mixed powder of Y 2 SiO 5 and Y 3 Al 5 O 12 The particle size is 15-65μm. Argon and hydrogen are used as plasma gases, argon is the main gas, and hydrogen is the secondary gas. The flow rate of hydrogen is 90L / min, and the flow rate of hydrogen is 10L / min. Under the conditions of a voltage of 40V and a current of 860A, the The powder feeding speed of 20g / min was carried out by plasma spraying at a distance of 150mm from the surface of the substrate to obta...

Embodiment 3

[0036] The aluminum substrate was cleaned and dried, and then the surface of the substrate was sandblasted under the conditions of a sandblasting pressure of 0.3Mpa and a sandblasting height of 350mm to obtain a substrate with a surface roughness Ra of 10μm. The sandblasted substrate is sprayed. Take Y with a particle size of 300-600nm in a mass ratio of 70:10:20 2 O 3 , Al 2 O 3 and SiO 2 powder, mixed and calcined at 1500°C for 3 hours to obtain Y 2 SiO 5 and Y 3 Al 5 O 12 of the mixed powder, prepared in the mixed powder of Y 2 SiO 5 and Y 3 Al 5 O 12 The particle size is 15-65μm. Argon and hydrogen are used as plasma gases, argon is the main gas, and hydrogen is the secondary gas. The flow rate of hydrogen is 60L / min, and the flow rate of hydrogen is 20L / min. Under the condition of voltage of 50V and current of 840A, The powder feeding speed of 30g / min was carried out by plasma spraying at a distance of 140mm from the surface of the substrate to obtain a com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com