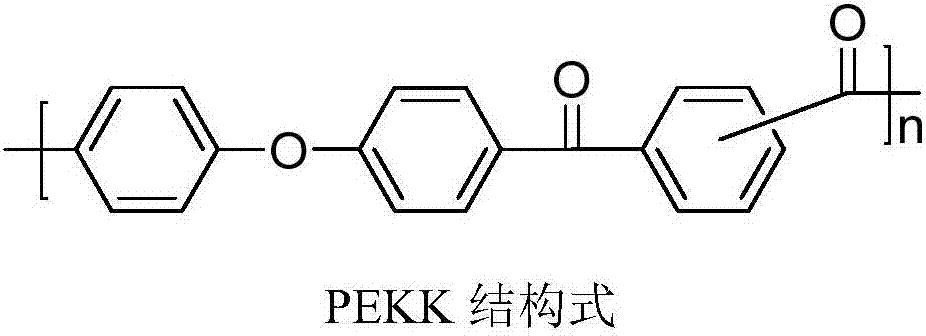

Preparation method of block polyether ketone ketone

A technology of polyether ketone ketone and prepolymer, which is applied in the field of preparation of block polyether ketone ketone, can solve the problems of high production cost, low single batch output, slow crystallization speed, etc., and achieve low cost and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

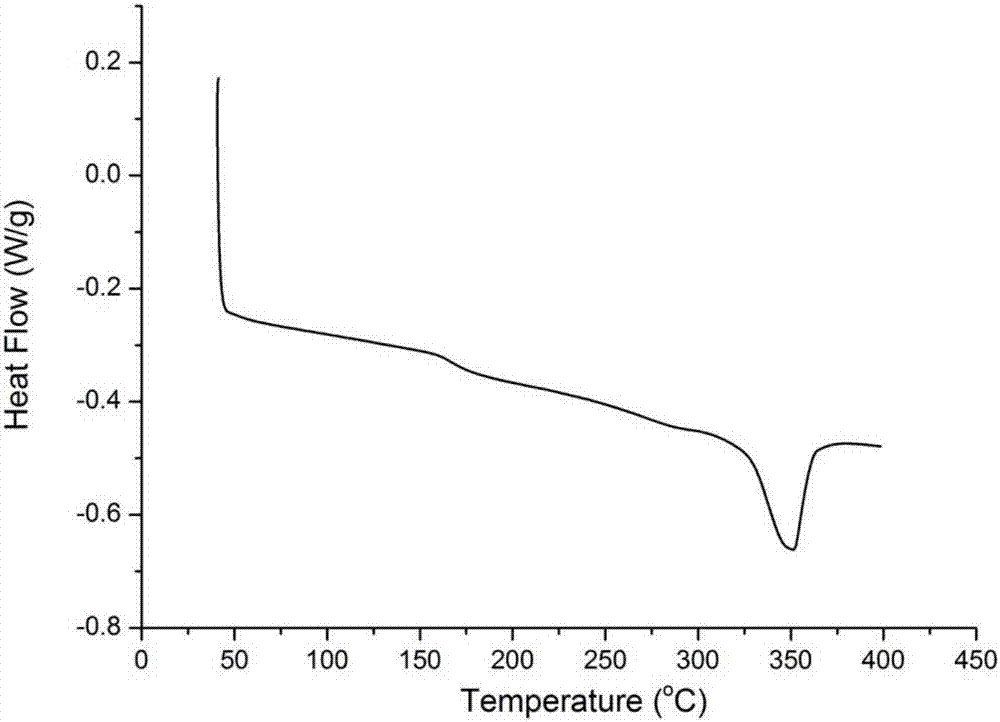

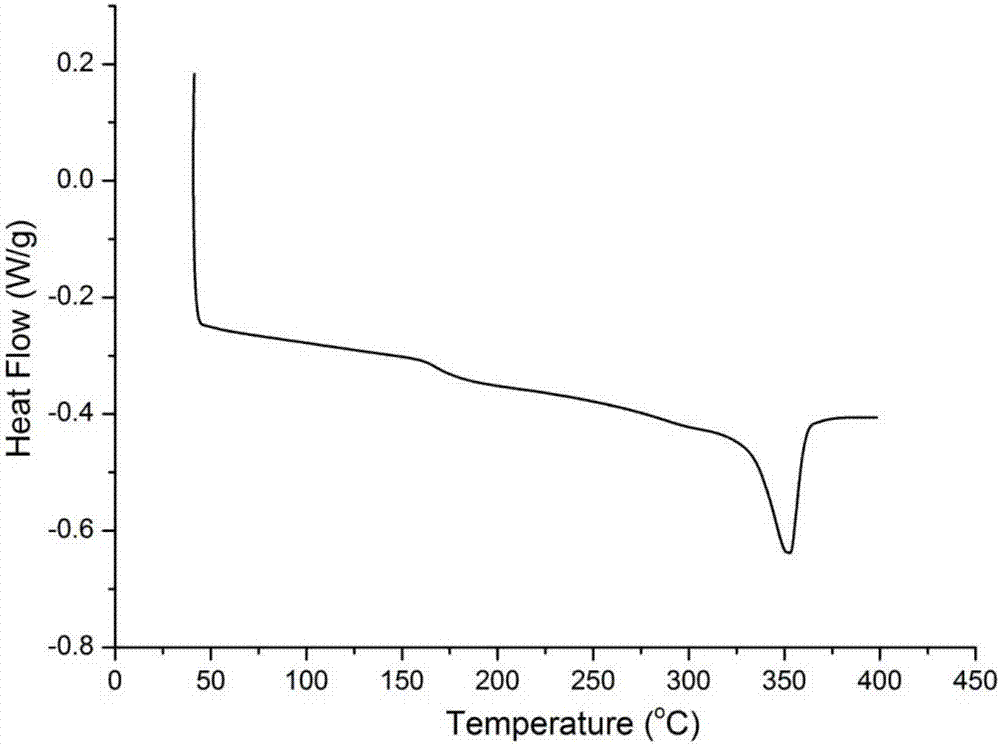

Examples

Embodiment 1

[0041]Add 49 mL of dichloromethane to A in a 100 mL round-bottomed three-necked flask equipped with mechanical stirring, a thermometer, and a nitrogen inlet and outlet tube, and use an ice-salt bath to lower the temperature of the flask to -10°C, and then add 11.15 mL in two batches under stirring. gN-methylpyrrolidone, and 50g of aluminum trichloride, during the addition process, ensure that the temperature in the reaction bottle does not exceed -5°C, after the addition is complete, continue to cool down to -15°C. In the resulting suspension, add 15.227g of terephthaloyl chloride, 12.766g of diphenyl ether and 15mL of dichloromethane dropwise under stirring. During the addition, ensure that the temperature in the reaction bottle does not exceed -5°C After the addition, wash the mixing bottle with 5mL of dichloromethane to ensure the complete transfer of the monomer, keep it at -15°C for 1 hour, then raise the temperature to 25°C, and continue the reaction for 2 hours to obtain...

Embodiment 2

[0043] Add 39 mL of dichloromethane to A in a 100 mL round-bottomed three-necked flask equipped with mechanical stirring, a thermometer, and a nitrogen inlet and outlet tube, and use an ice-salt bath to lower the temperature of the flask to -10°C, and then add 8.92 in two batches under stirring. gN-methylpyrrolidone, and 40g of aluminum trichloride, during the addition process, ensure that the temperature in the reaction bottle does not exceed -5°C, after the addition is complete, continue to cool down to -15°C. In the resulting suspension, add a mixture of 12.181g of terephthaloyl chloride, 10.213g of diphenyl ether and 12mL of methylene chloride dropwise under stirring. During the addition, ensure that the temperature in the reaction bottle does not exceed -5°C After the addition, wash the mixing bottle with 12 mL of dichloromethane to ensure the complete transfer of the monomer, keep it at -15°C for 1.5 hours, then raise the temperature to 25°C, and continue the reaction for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com