Copolymerized aramid dope-dyed yarn and method for preparing same

A technology of dope dyeing and aramid fiber, applied in the direction of adding dyes in spinning solution, single-component copolyamide rayon filament, adding pigment in spinning solution, etc. Small, deteriorating dyeing performance and other problems, to achieve the effect of improving color strength and preventing the reduction of polymerization degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] Will contain 3wt.% CaCl 2 The N-methyl-2-pyrrolidone (NMP) organic solvent injects in the reactor under nitrogen atmosphere, then in this reactor, the p-phenylenediamine of 50mol% and the cyano-p-phenylenediamine of 50mol% are introduced and dissolved to Prepare mixed solutions.

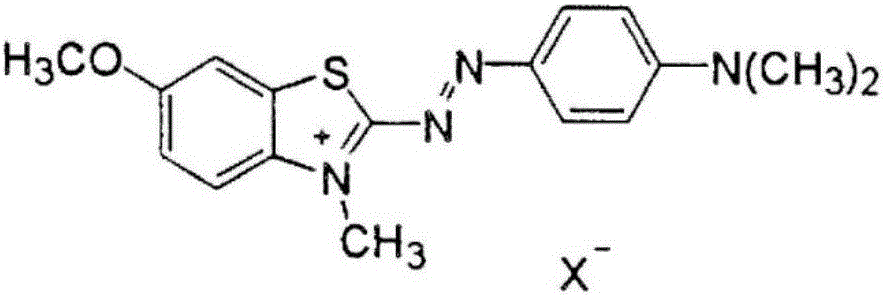

[0081] Then, 100mol% of terephthaloyl chloride and 0.3wt.% of C.I. Basic Black 2 (relative to the weight of the copolymerized aramid fiber) were simultaneously added to the reactor including the mixed solution to prepare a mixture containing the copolymerized aramid fiber Polymerization solutions of polymers.

[0082] Thereafter, after the polymerization solution was extruded through the spinning spinneret, the air gap and the coagulant were sequentially passed through the spinning spinneret, thereby forming multifilaments having a linear density of 3,000 denier. The spin pack pressure was 2,800 psi and the spin speed was 600 mpm (meters per minute).

[0083] Thereafter, the multifilaments ...

Embodiment 2

[0086] Will contain 3wt.% CaCl 2 The N-methyl-2-pyrrolidone (NMP) organic solvent was injected into a reactor under a nitrogen atmosphere, and then 100 mol% of cyano-p-phenylenediamine was introduced into the reactor and dissolved to prepare a mixed solution.

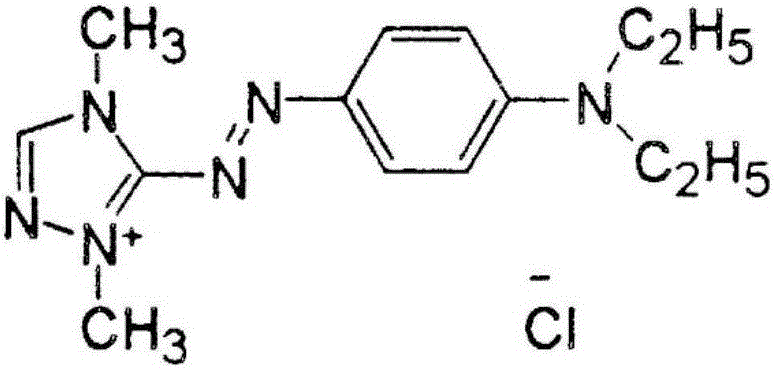

[0087] Then, 100mol% of terephthaloyl chloride and 1.5wt.% of C.I. Basic Blue 22 (relative to the weight of the copolymerized aramid fiber) were simultaneously added to the reactor including the mixed solution to prepare a mixture containing the copolymerized aramid fiber Polymerization solutions of polymers.

[0088] Thereafter, after the polymerization solution was extruded through the spinning spinneret, the air gap and the coagulant were sequentially passed through the spinning spinneret, thereby forming multifilaments having a linear density of 3,000 denier. The spin pack pressure was 2,800 psi and the spin speed was 600 mpm (meters per minute).

[0089] Thereafter, the multifilaments were washed, and then the wa...

Embodiment 3

[0092] Will contain 3wt.% CaCl 2 The N-methyl-2-pyrrolidone (NMP) organic solvent injects in the reactor under nitrogen atmosphere, then in this reactor, the p-phenylenediamine of 50mol% and the cyano-p-phenylenediamine of 50mol% are introduced and dissolved to Prepare mixed solutions.

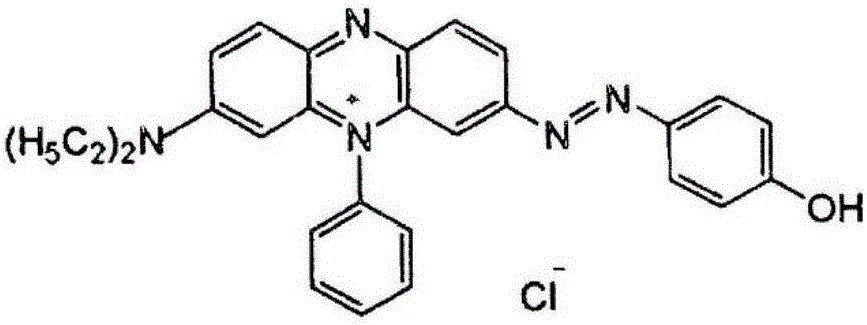

[0093] Then, 100mol% of terephthaloyl chloride and 3wt.% of C.I. Basic Blue 64 (relative to the weight of the copolymerized aramid polymer) were simultaneously added to the reactor including the mixed solution to prepare a polymer containing the copolymerized aramid fiber. polymer solution.

[0094] Thereafter, after the polymerization solution was extruded through the spinning spinneret, the air gap and the coagulant were sequentially passed through the spinning spinneret, thereby forming multifilaments having a linear density of 3,000 denier. The spin pack pressure was 2,800 psi and the spin speed was 600 mpm (meters per minute).

[0095] Thereafter, the multifilaments were washed, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com