Para-aramid precipitation fiber and continuous production method thereof

A production method, para-aramid technology, applied in the field of para-aramid precipitated fiber and its continuous production, can solve the problem of long process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

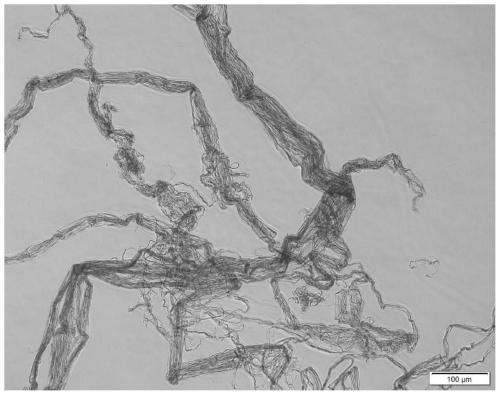

Image

Examples

Embodiment 1

[0067] (1) Under the condition of nitrogen protection, through the transfer pump to 1m 3 Put dehydrated NMP750L into the dissolution kettle, then add 46.26kg of calcium chloride under stirring, dissolve at 93°C, and obtain a calcium chloride solution after dissolving for 35min, then lower the temperature in the dissolution kettle to 0°C; then Add 16.23kg p-phenylenediamine (PPD) under stirring, stir and dissolve for 45min to obtain p-phenylenediamine solution;

[0068] (2) The p-phenylenediamine solution and the terephthaloyl chloride melt kept at 105°C are precisely metered by a metering pump, and then directly transported to a twin-screw reactor by a delivery pump for polymerization, wherein the precise control is carried out by a metering pump The molar ratio of terephthaloyl chloride and p-phenylenediamine into the screw reactor is (1.00~1.005):1;

[0069] The length-to-diameter ratio of the twin-screw reactor is 40:1, the rotation speed is 200 rpm, and the outlet tempera...

Embodiment 2

[0075] (1) Under the condition of nitrogen protection, through the transfer pump to 1m 3 Put dehydrated NMP750L into the dissolution kettle, then add 30.84kg magnesium chloride under stirring, dissolve at 90°C, and obtain a magnesium chloride solution after dissolving for 40min, then lower the temperature in the dissolution kettle to 5°C; then add 32.45kg p-phenylenediamine (PPD), stirring and dissolving 40min, obtains p-phenylenediamine solution;

[0076] The p-phenylenediamine solution and the terephthaloyl chloride melt kept at 107°C are accurately metered by a metering pump, and then directly transported to the twin-screw reactor by a delivery pump for polymerization. The molar ratio of formyl chloride and p-phenylenediamine added to the screw reactor is (1.00~1.003):1;

[0077] The length-to-diameter ratio of the twin-screw reactor is 50:1, the rotation speed is 150 rpm, and the outlet temperature at the end of the screw is kept below 70°C. The twin-screw reactor has tw...

Embodiment 3

[0082] (1) Under the condition of nitrogen protection, through the transfer pump to 1m 3 Put 750L of dehydrated DMAc into the dissolution kettle, then add 61.68kg of aluminum chloride under stirring, dissolve at 94°C, and obtain a lithium chloride solution after dissolving for 35min, then lower the temperature in the dissolution kettle to -3°C; Then add 48.65kg p-phenylenediamine (PPD) under stirring, stir and dissolve for 50min to obtain p-phenylenediamine solution;

[0083] (2) The p-phenylenediamine solution and the terephthaloyl chloride melt kept at 103°C are accurately metered by a metering pump, and then directly transported to a twin-screw reactor by a delivery pump for polymerization. The molar ratio of terephthaloyl chloride and p-phenylenediamine into the screw reactor is (1.00~1.008):1;

[0084] The length-to-diameter ratio of the twin-screw reactor is 55:1, the rotation speed is 80 rpm, and the outlet temperature at the end of the screw is kept below 70°C. The t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com