Hydrotreatment method of heavy hydrocarbon raw material

A hydroprocessing and raw material technology, which is applied in hydroprocessing process, hydrocarbon oil treatment, petroleum industry, etc., can solve the problems of reducing liquid recovery, light oil loss, etc., and achieve optimized operation, extended service life, and wide adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

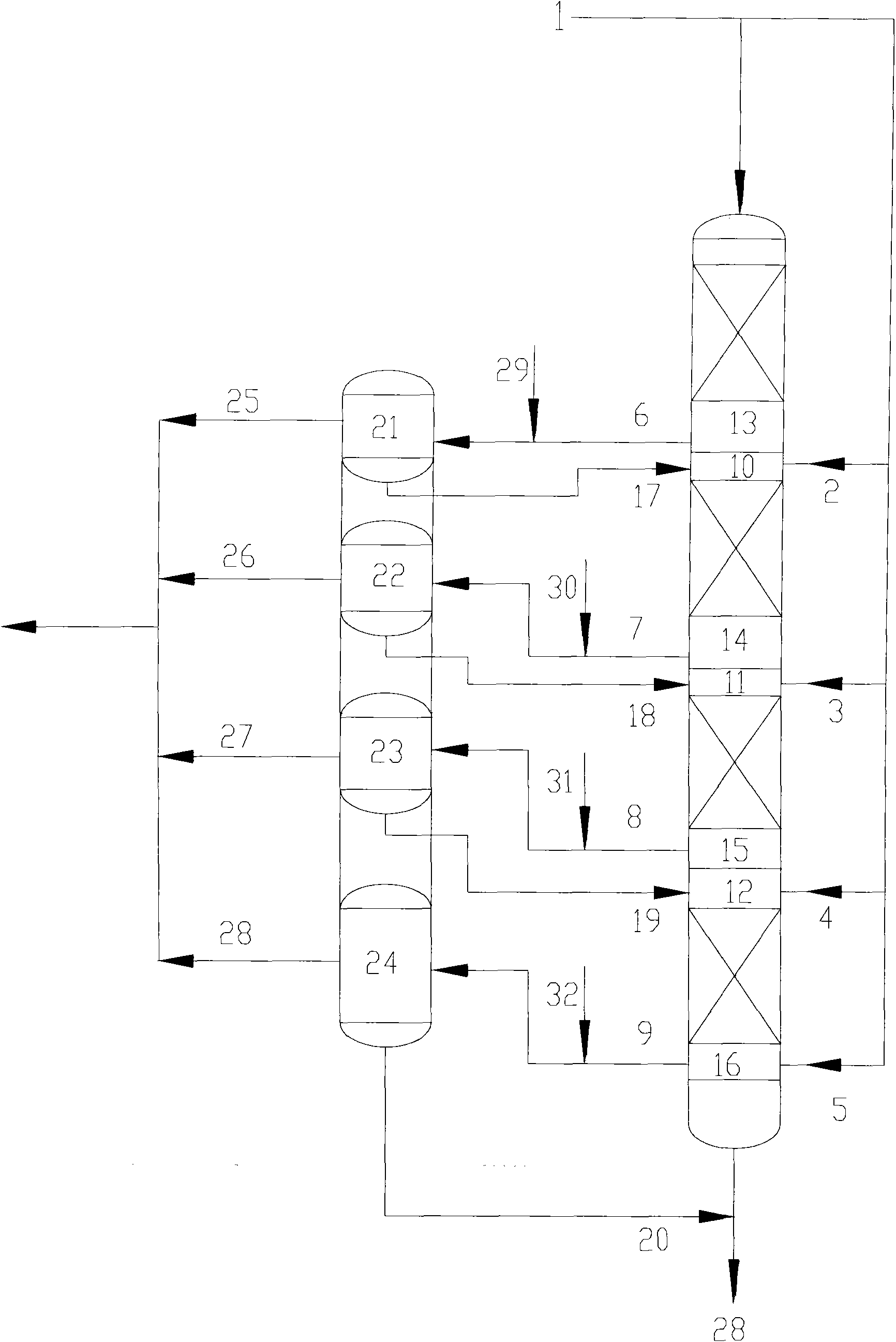

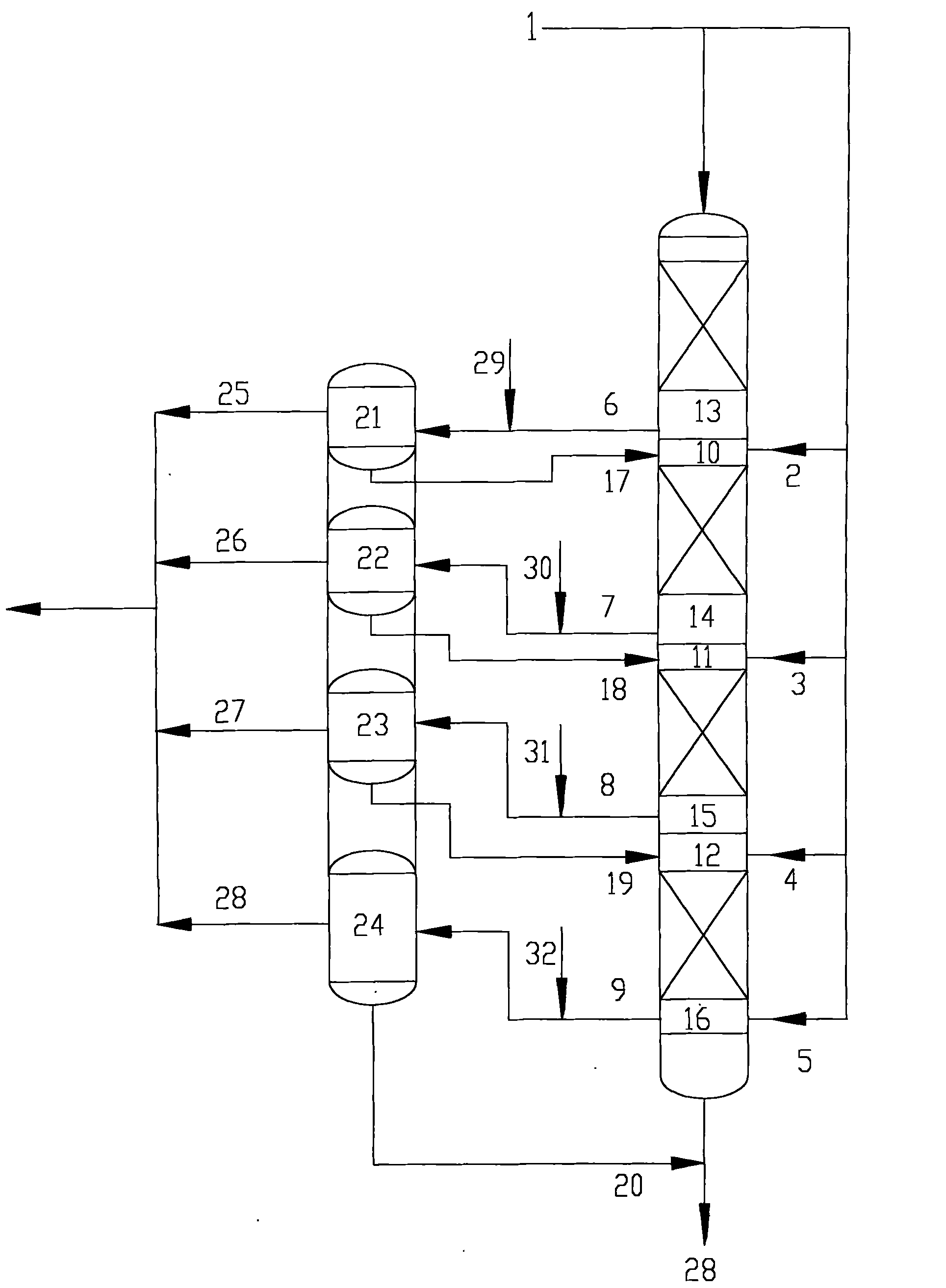

Method used

Image

Examples

Embodiment 1

[0031] The fixed-bed residual oil hydrogenation reactor has three catalyst beds in total. The three catalyst beds are filled with the same catalyst, and the three catalyst beds have the same loading amount of catalyst. The residual oil and hydrogen enter the fixed-bed reaction through the pipeline after being heated. The hydrogenation reaction occurs in the first bed of the reactor, and the reaction conditions are as follows: temperature 360°C; pressure 15.0MPa, volumetric space velocity of residual oil feed 0.5h -1 ; The hydrogen-oil ratio at the reactor inlet is 1300 (V / V). The solvent is propane, and the cold oil is petroleum distillate at 320-420°C. The liquid phase at the outlet of the first bed and the second bed is taken out of the reactor and mixed with the solvent for extraction. The extracted light components are further utilized, and the remaining heavy components are Return to the hydrogenation reactor, introduce cold oil to the reactor at the same time, and when t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com