Manufacturing method of medium temperature heat pipe heat collecting pipe for solar energy internal concentration

A heat-collecting tube and solar energy technology, which is applied in the production field of solar energy concentrating medium-temperature heat-collecting tubes, can solve the problems of annealing deformation of reflectors, reduction of air tightness and strength, and cracking and dripping of fried tubes, so as to speed up the temperature rise The effect of mass transfer and heat transfer speed, reduction of manufacturing and use costs, and improvement of heat and mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

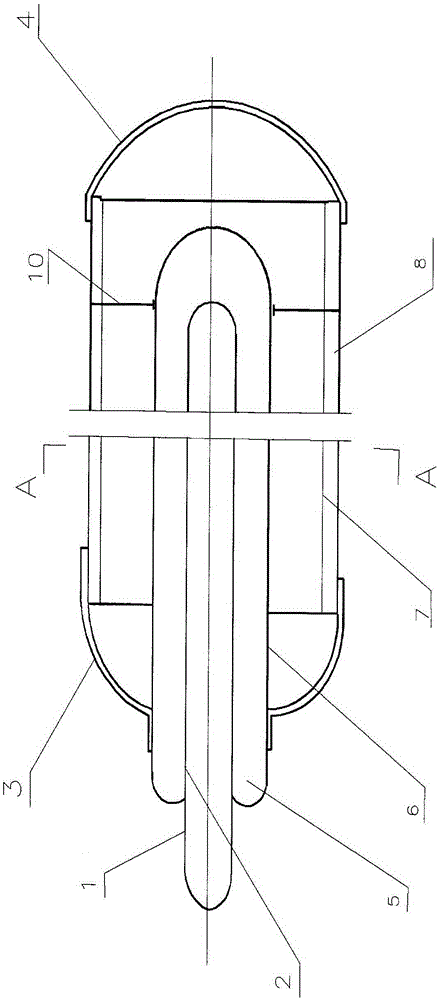

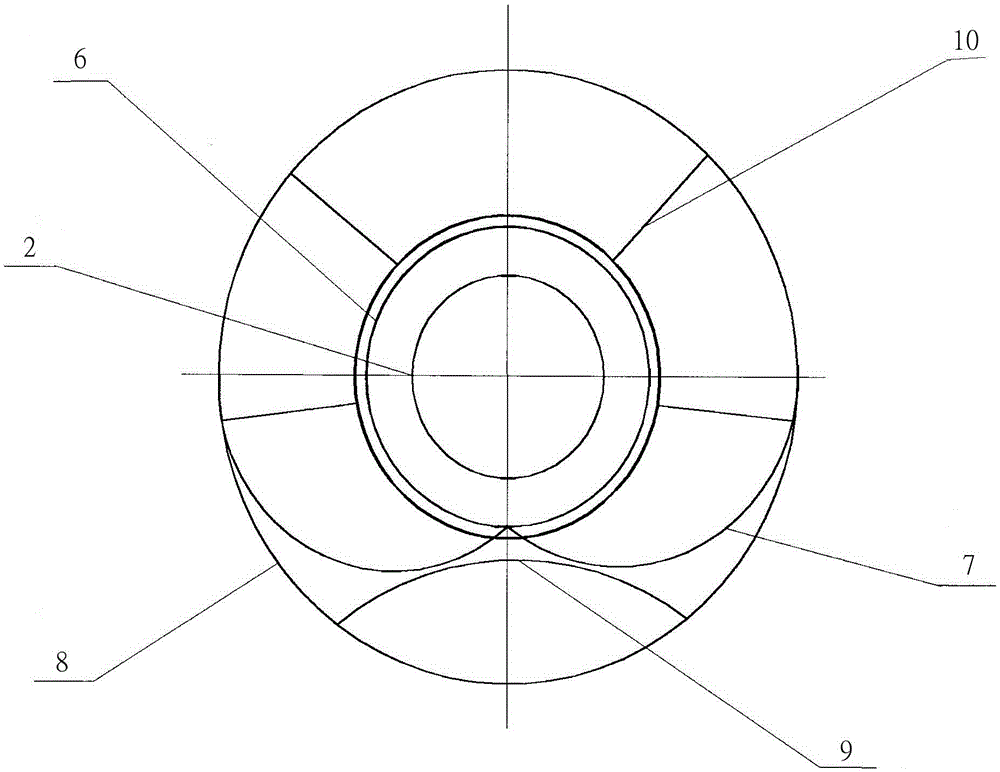

[0029] Below, the present invention will be further described by taking the accompanying drawings as examples. Such as figure 1 , 2 As shown, the solar energy concentrating medium-temperature heat collecting tube is composed of an outer cover tube 8 made of a light-transmitting material, a coaxial vacuum cover tube 6, a heat-absorbing tube 2, a concentrating plate 7, an upper end cover 3, a lower end cover 4, and a heat dissipation end tube 1 composition; the vacuum cover tube 6 and the outer cover tube 8 are arranged coaxially on the outside of the heat absorbing tube 2 in turn, and the concentrating plate 7 is arranged between the outer cover tube 8 and the vacuum cover tube 6, and the concentrating plate 7 is a composite parabolic reflector , the light-condensing plate 7 is assembled on the arc surface of the lower half of the inner wall of the outer cover tube 8, and a support card 9 is equipped between the outer cover tube 8 and the light-condensing plate 7. The upper e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com