Sprayed concrete material conveying and mixing system

A shotcrete and mixing system technology, applied in the directions of transportation and packaging, loading/unloading, etc., can solve the problems of deteriorating the working environment of workers, threats to human health, and increasing the cost of enterprises, so as to reduce dust pollution, be beneficial to health, and save money. The effect of business costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

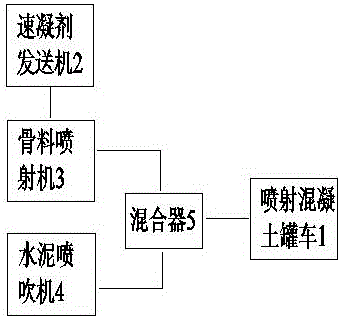

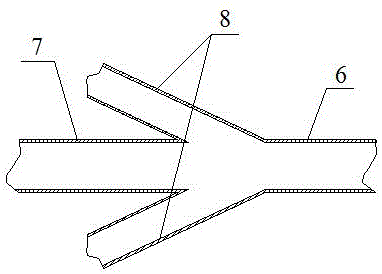

[0040] like figure 1 As shown, the sprayed concrete material conveying and mixing system of the present invention is composed of a sprayed concrete tank truck 1, an accelerator sending machine 2, an aggregate spraying machine 3, a cement blowing machine 4 and a mixer 5. like figure 2 As shown, the mixer 5 is composed of a discharge pipe 6 , an aggregate feed pipe 7 and two cement feed pipes 8 . Aggregate feed pipe 7 communicates with discharge pipe 6 , and cement feed pipe 8 communicates with aggregate feed pipe 7 . The accelerator sending machine 2 is connected with the aggregate injection machine 3, the aggregate injection machine 3 is connected with the aggregate feeding pipe 7 of the mixer 5, and the cement injection machine 4 is connected with the cement feeding pipe 8 of the mixer 5. Connection, the discharge pipe 6 of the mixer 5 is connected with the shotcrete tank truck 1.

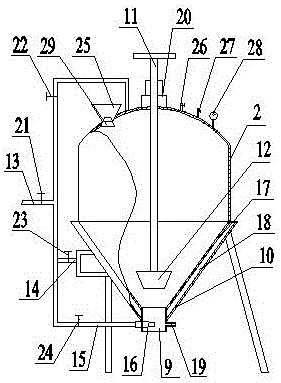

[0041] like image 3 As shown, the quick-setting agent sender 2 includes a discharge pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com