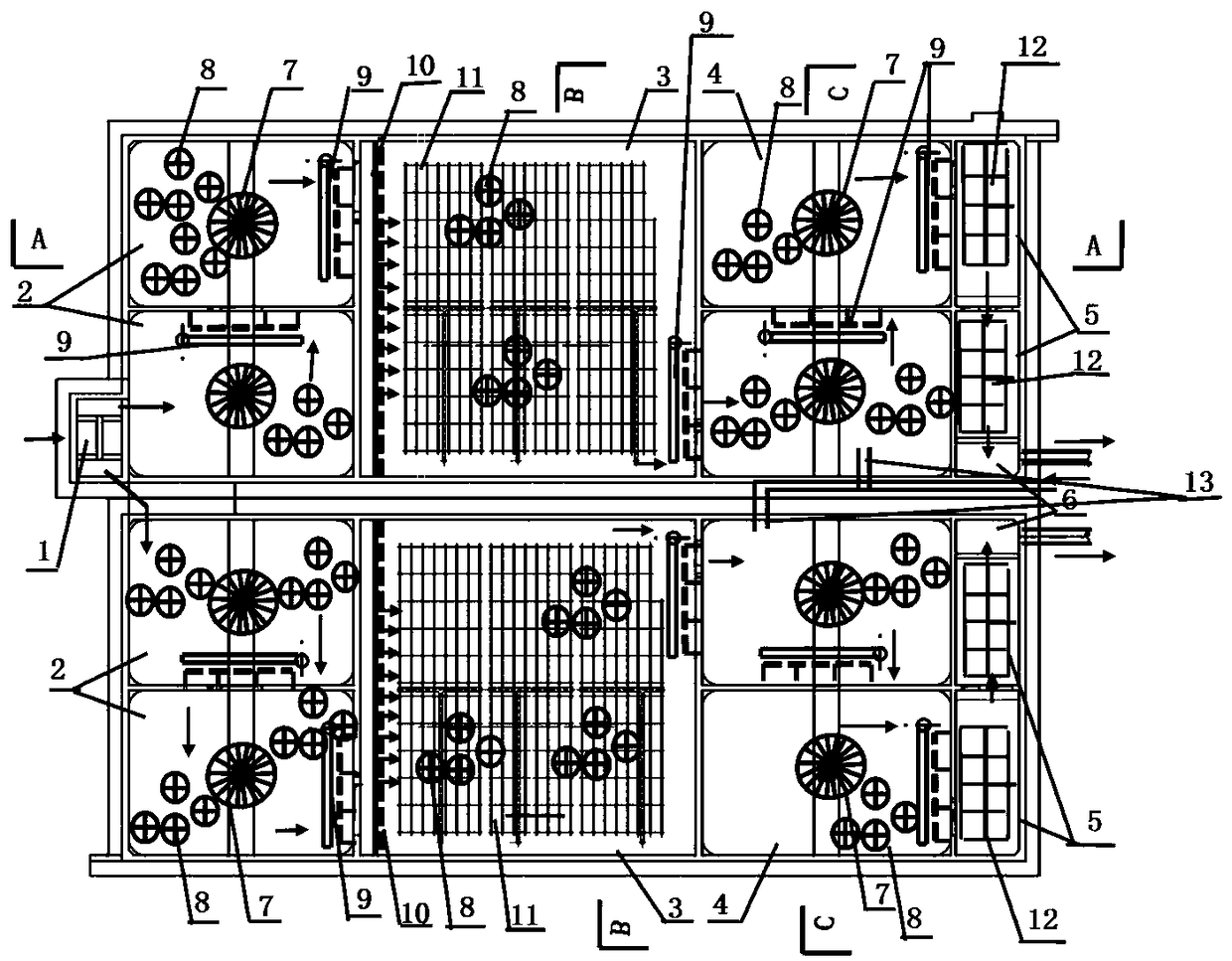

AOAO mud chemical wastewater treatment method

A treatment method and technology for chemical wastewater, applied in water/sludge/sewage treatment, multi-stage water treatment, anaerobic digestion treatment, etc., can solve problems such as insufficient effects, increase biomass, improve volume utilization, and ensure The effect of nitrification capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

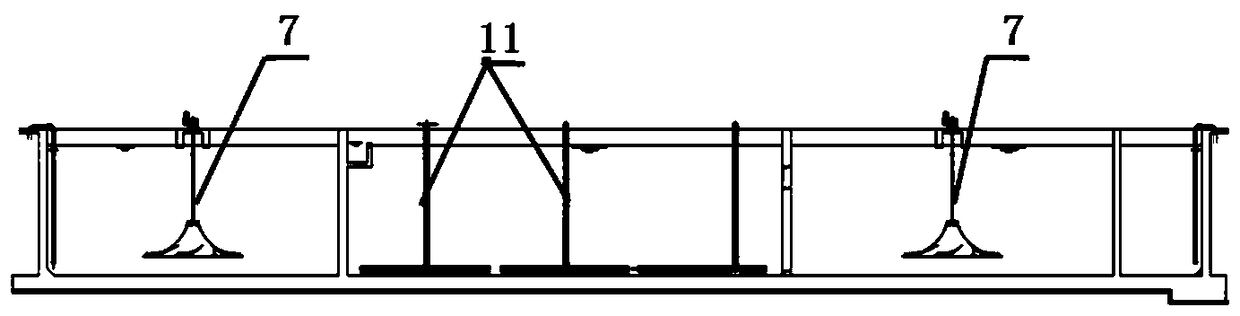

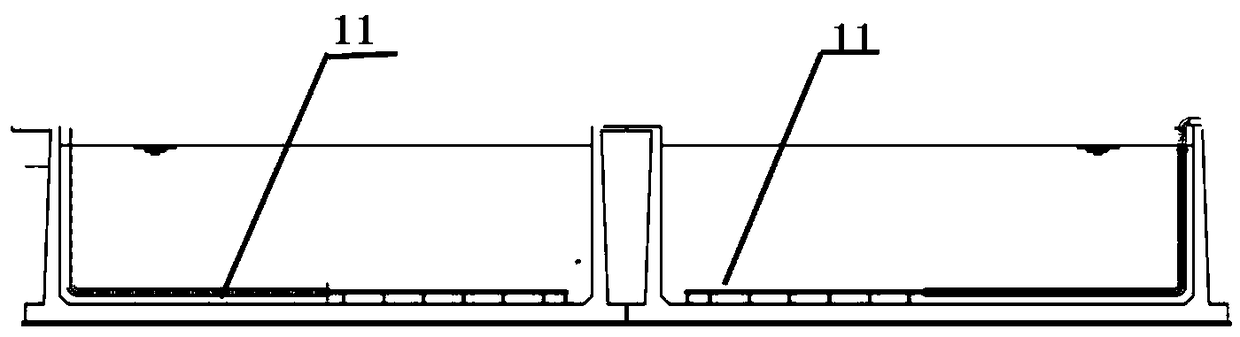

Method used

Image

Examples

example 1

[0039] A certain coal chemical industry wastewater volume is 20000m³ / day. The sources of wastewater include urea wastewater, centrifuge wastewater, synthetic ammonia wastewater, flare wastewater, hydrogen peroxide workshop wastewater, hot spot plant wastewater, nitric acid workshop wastewater, glycol workshop wastewater, methylamine wastewater, and Part of workshop wastewater. The influent COD concentration is 150mg / L, BOD concentration is 60mg / L, NH4-N concentration is 80mg / L, TN is 130mg / L, TP is 1.0mg / L, which belong to the previous traditional activated sludge biochemical process pretreatment Coal chemical wastewater with high ammonia nitrogen and TN but low COD. Using the invention, the total volume of the added suspended carrier is 8000m³. In the initial start-up after the completion of the facility construction, in order to quickly cultivate the ability of domesticated sludge, biofilm and the verification system to remove COD, the water inflow is large, and the overload...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com