Fluidized bed reactor gases distributing plate

A fluidized bed reactor and gas distribution plate technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve problems such as dead holes, limited range of action, and influence on reaction yield, and achieve enhanced anti-deposition ability, Easy cleaning and modification, and increased operational stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

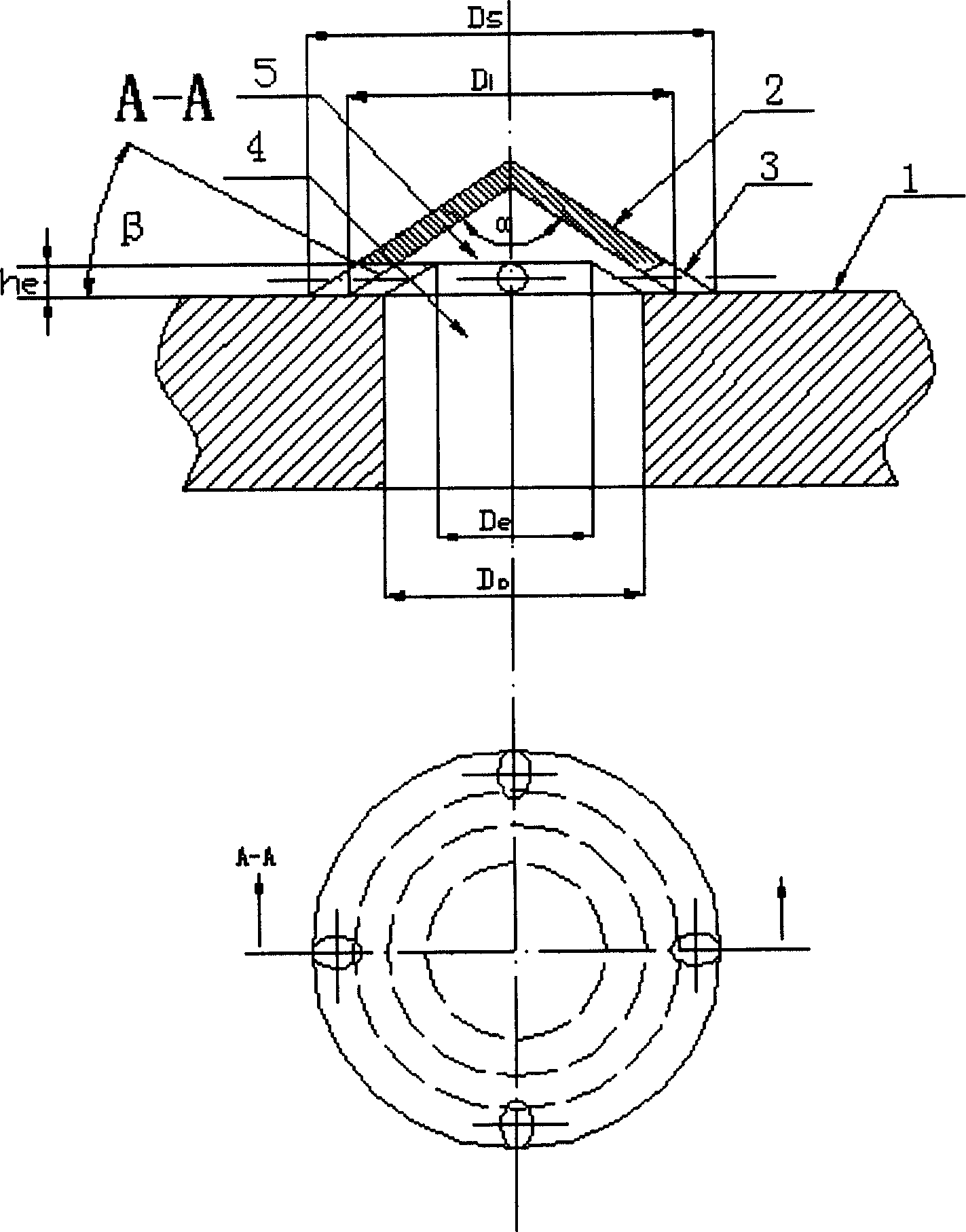

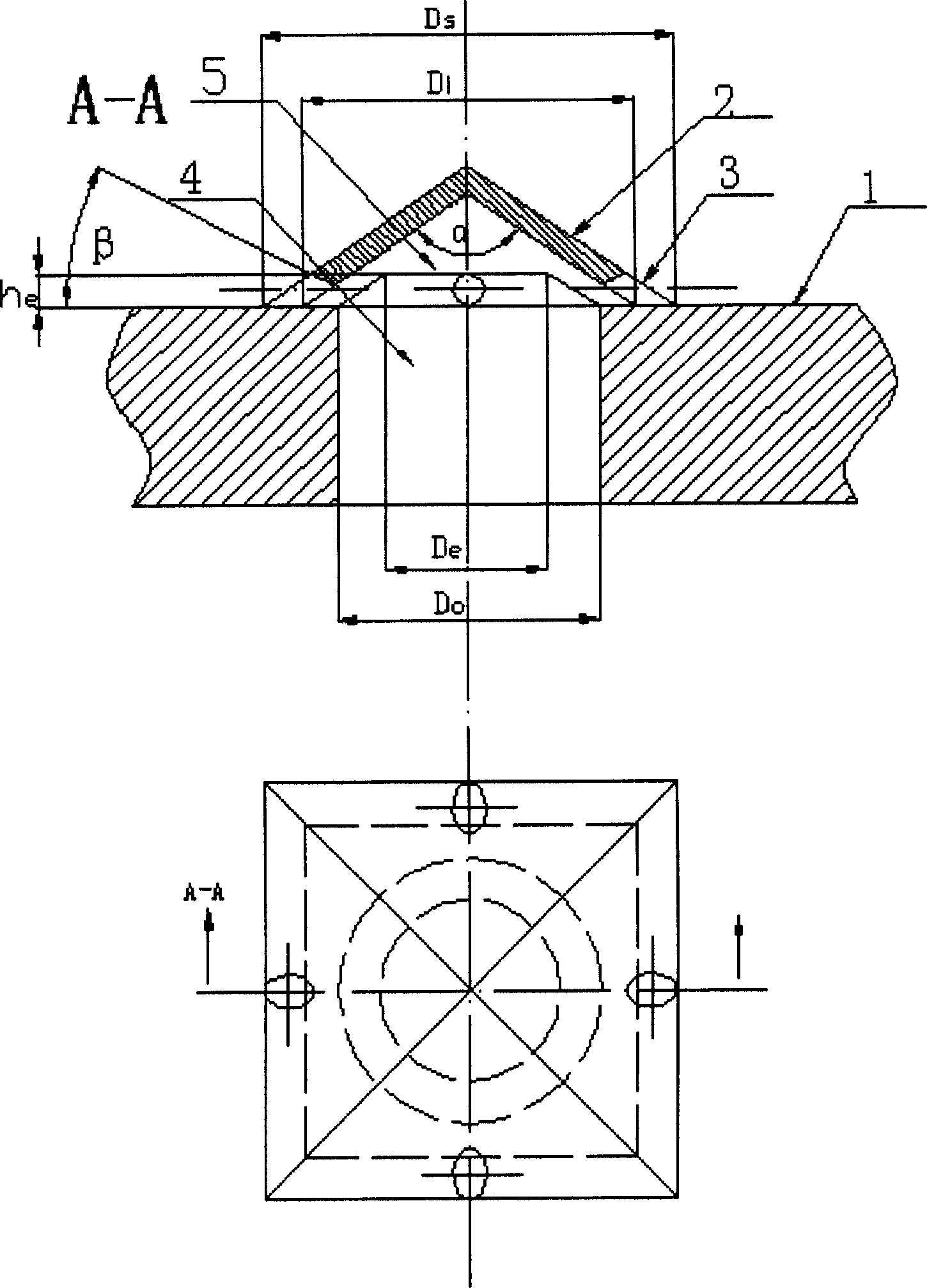

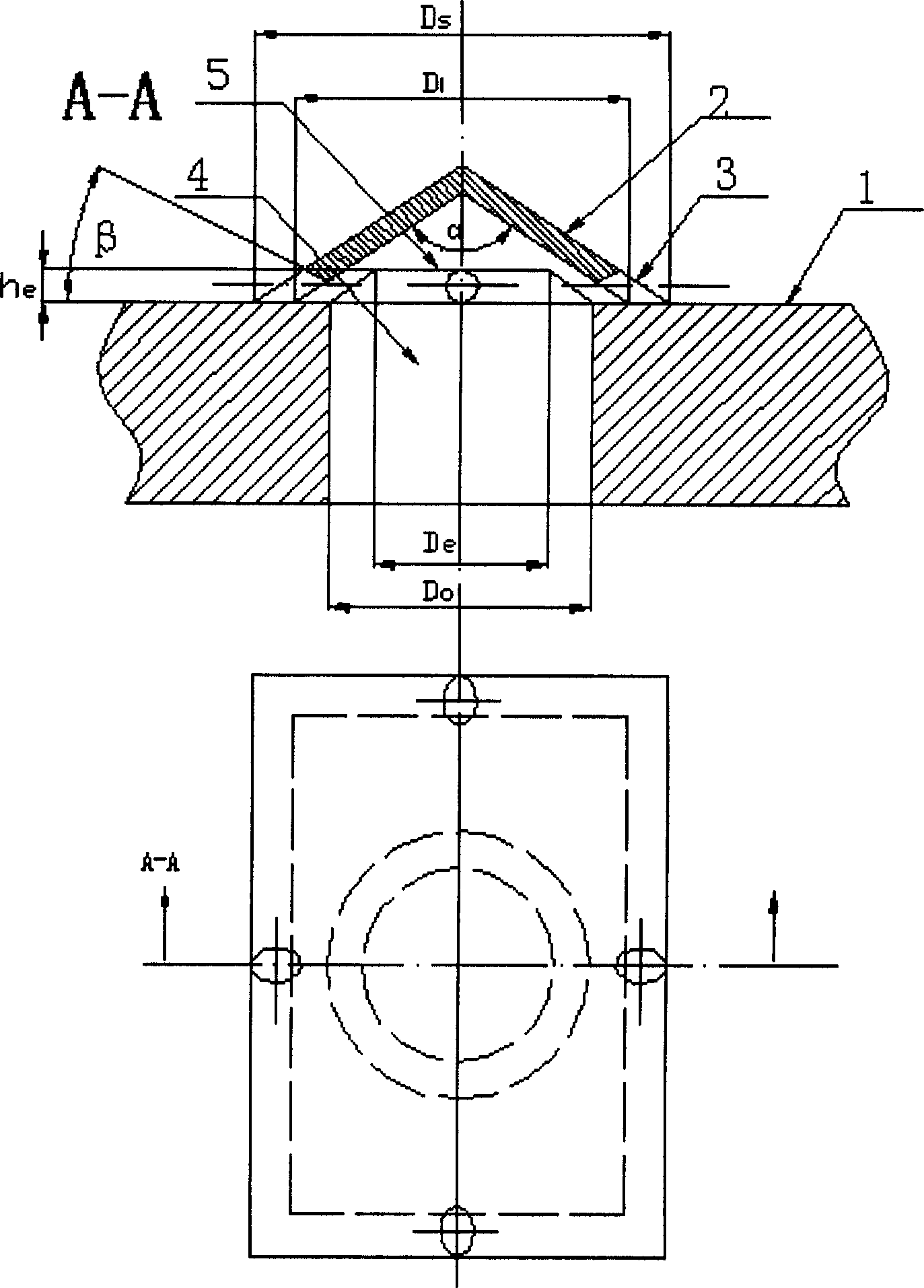

[0033] The Unipol fluidized bed olefin polymerization reactor imported from United Carbon is used, and the bottom installation is as follows figure 1 and the distributor plate of the present invention shown in 4. Operated in condensing mode, high density polyethylene is produced.

[0034] 1) Operating data of density polyethylene products

[0035] Reaction raw materials: ethylene, propylene, 1-butene, hydrogen

[0036] Liquid content in recycle stream: 9%~26%wt

[0037] Space-time yield: 134.8kgPE / m 3 *hr

[0038] 2) The case of continuous operation for 12 months:

[0039] The circulation flow rate is stable and there is no obvious fluctuation, which proves that the distribution plate is atomized evenly.

[0040] There is no increase in the pressure difference of the distribution plate, and it is always maintained at 2700-2970kg / m 3 Between, indicating that the distribution plate is not clogged.

[0041] The temperature of the four temperature detection points on the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com