Device and method for carrying out chemical energy storage/release by utilizing carbide slag

A calcium carbide slag and chemical technology, applied in the field of thermal energy storage, can solve problems such as complex technological processes, achieve the effects of saving calcium-based materials, alleviating environmental pollution, and enhancing mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

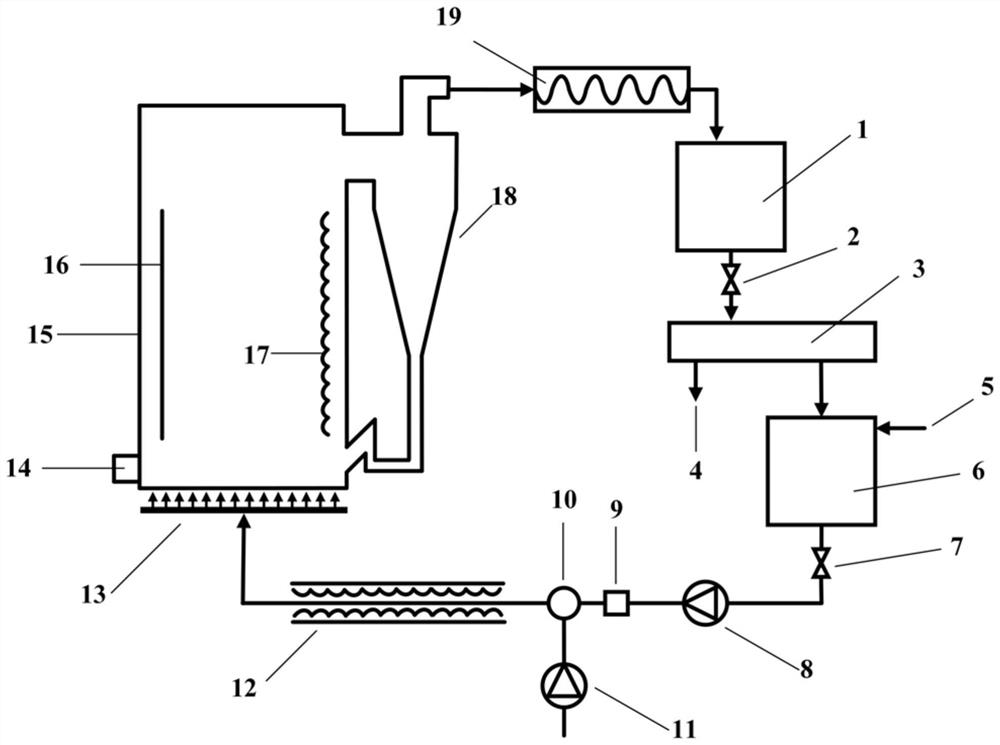

[0054] A device for chemical energy storage / discharge using carbide slag, such as figure 1 As shown, it includes primary water tank 1, primary valve 2, purified water tank 3, slag discharge port 4, water replenishment port 5, secondary water tank 6, secondary valve 7, water pump 8, atomizing nozzle 9, switching valve 10, fan 11. Electric heater 12, gas distribution plate 13, inlet / discharge port 14, circulating fluidized bed reactor 15, built-in electric heating plate 16, built-in heat exchange tube 17, vapor particle separator 18, and condenser 19.

[0055] Put the powdery calcium carbide slag directly into the circulating fluidized bed reactor 15 through the inlet / discharge port 14 without screening; during the energy storage process, close the primary valve 2, open the secondary valve 7, and the secondary water tank 6 The pre-stored liquid water enters the atomizing nozzle 9 through the water pump 8 to generate atomized droplet groups, which are heated and vaporized by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com