Sewage treating system for micro-aerobic expanded granular sludge bed-steel slag biological filter pond

A technology for expanding granular sludge and sewage treatment systems, applied in water/sludge/sewage treatment, sustainable biological treatment, multi-stage water/sewage treatment, etc. Problems such as large excess sludge output, etc., achieve the effect of improving operating efficiency, strengthening phosphorus removal effect, and reducing aeration energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

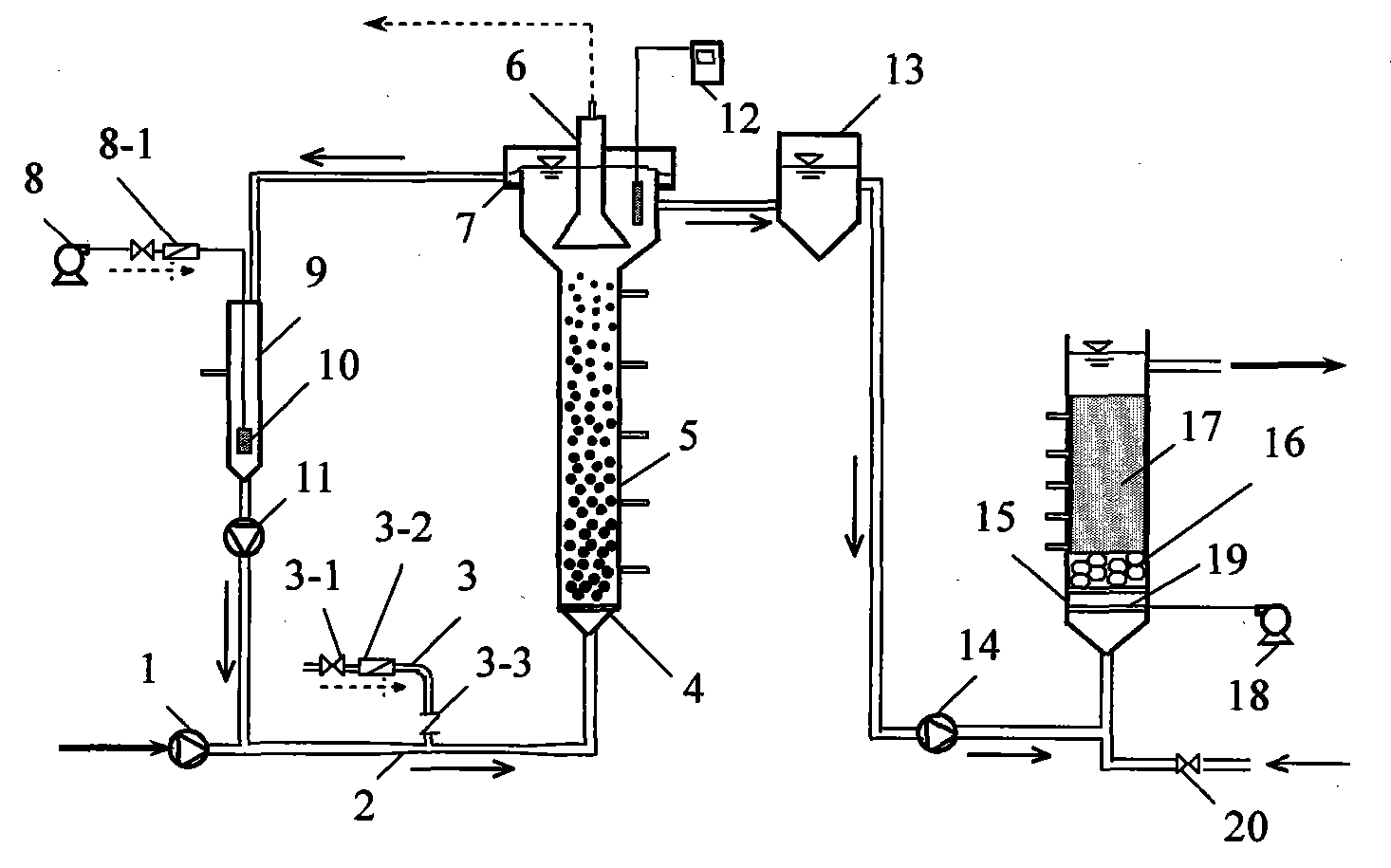

[0016] The present invention will be described below in conjunction with the accompanying drawings.

[0017] After the sewage influent is combined with the oxygenated reflux water of the micro-oxygen expanded granular sludge bed reactor, when it passes through the jet suction nozzle 2, a negative pressure is generated in the nozzle, and a certain amount of air is sucked in by the suction pipe 3, and then passes through the porous The water distribution plate 4 enters the micro-aerobic reaction zone 5 from the bottom, fully contacts and reacts with the micro-aerobic granular sludge, and organic pollutants are degraded, and the nitrification and denitrification processes carried out at the same time realize the transformation and removal of nitrogen, and the mixed solution passes through three stages. The phase separator 6 is effectively separated, the gas is discharged from the top of the three-phase separator, and a part of the clarified liquid enters the aeration column 9 thro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com