Pressure container and gas inlet thereof

A pressure vessel and air inlet technology, which is applied in the field of pressure vessels and their air inlets, can solve the problems of insufficient improvement of the flow state factor entering the shell, difficulty in setting the material inlet and outlet 5, and failure to fundamentally solve the problem, etc. The layout is safe and scientific, the particle size and ingredient quality are uniform, and the operation is flexible.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

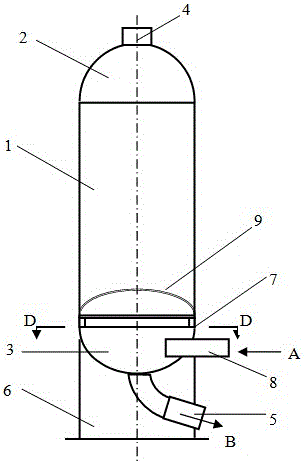

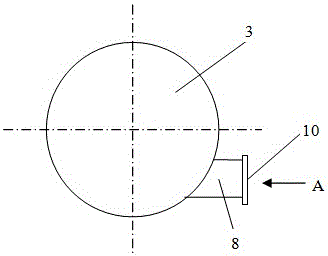

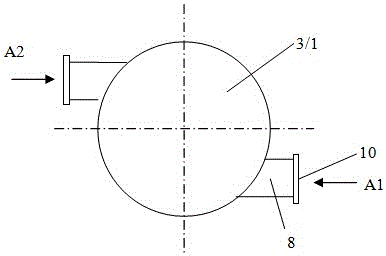

[0050] A pressure vessel and its air inlet of the present invention, the air inlet is located on the cylinder or head below the lower distribution plate in the vertical pressure vessel shell, specifically, refer to image 3 The truncation to the dual inlet takes over, with the figure 2 Compared with the traditional single inlet nozzle, there is only one more inlet nozzle, and its manufacturing process remains unchanged, but the diameter of the nozzle can be reduced under the same process air flow rate, which should be determined through design calculations.

[0051] The tangential direction refers to the intersection of the busbar on the long side and the arc of the head 3 or the cylinder 1 to form a bow.

Embodiment 2

[0053] The second specific embodiment of a pressure vessel and its axisymmetric air inlet of the present invention, refer to Figure 4 As shown, the main technical solutions of this embodiment are the same as those of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. The difference between this embodiment and Embodiment 1 is that the number of the non-radial and tangential intake pipes increases from two evenly distributed to three.

Embodiment 3

[0055] The third specific embodiment of a pressure vessel and its axisymmetric air inlet of the present invention, refer to Figure 5 As shown, the main technical solutions of this embodiment are the same as those of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. The difference between this embodiment and Embodiment 1 is that the tangential inlet connection is a connection structure with two-sided openings tangential to the shell, and the tangential direction refers to the circle between the long-side busbar and the head 3 or cylinder 1. The smooth transition of the arcs is tangent to each other, and no longer cuts out a bow.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com