Gas distributor and reactor

A gas distributor and reactor technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve problems such as general performance, impossibility of improvement, waste of reactor volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

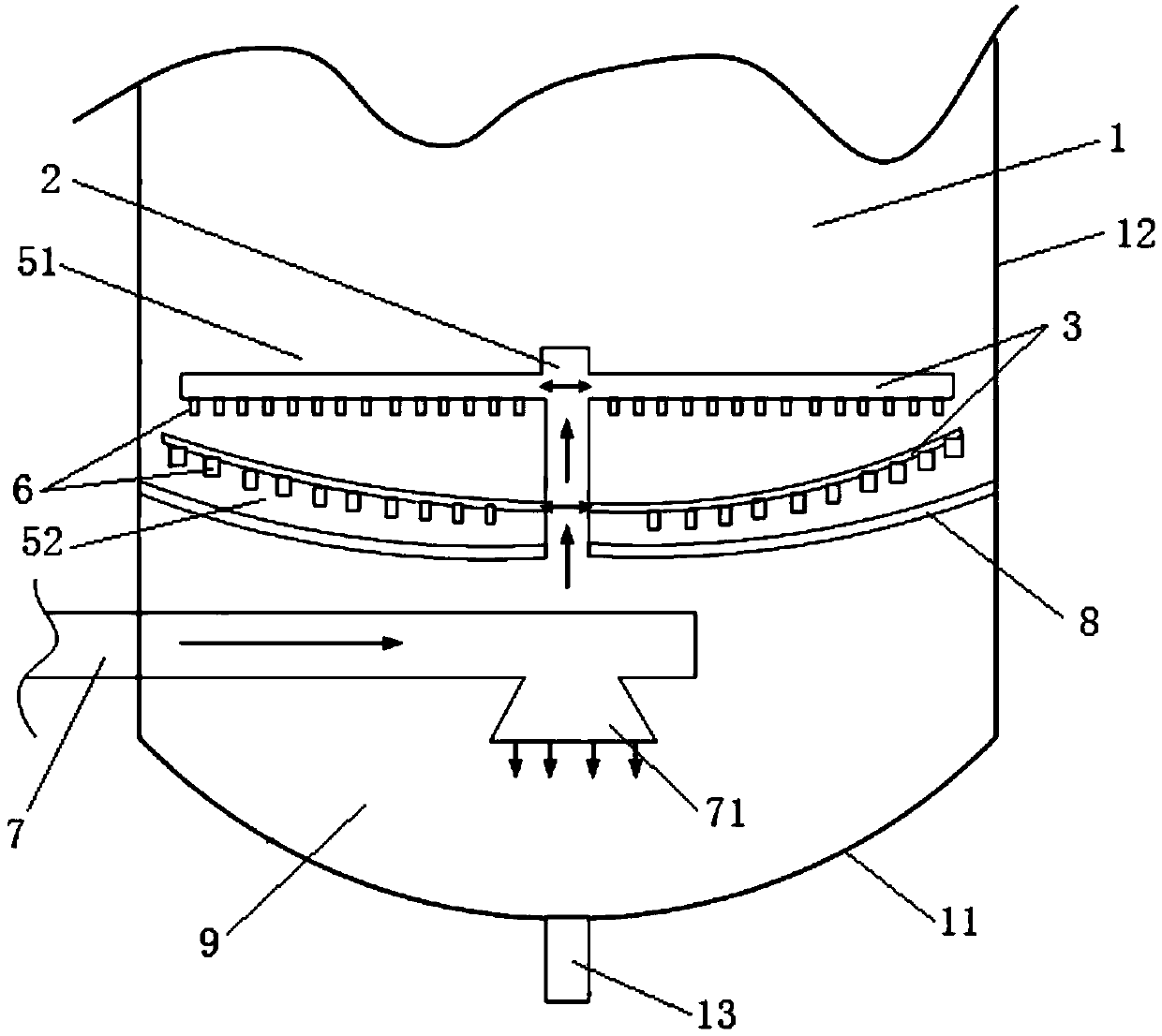

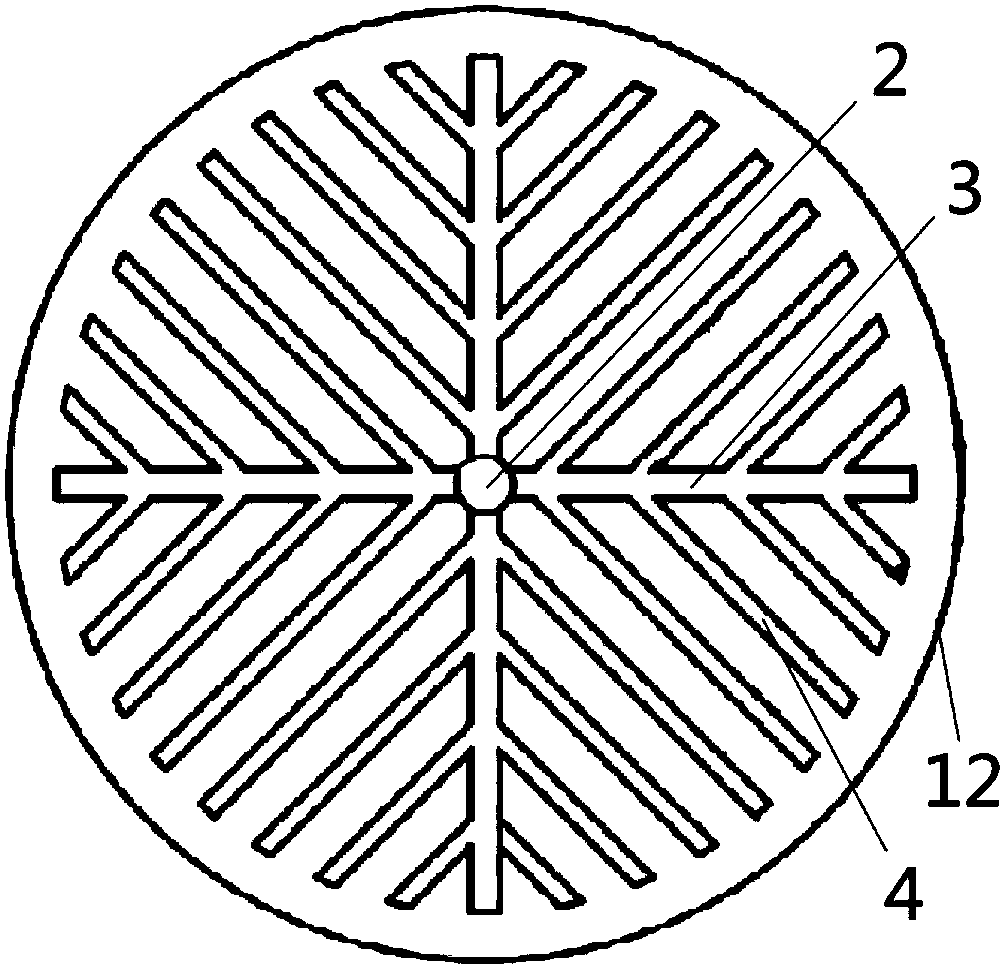

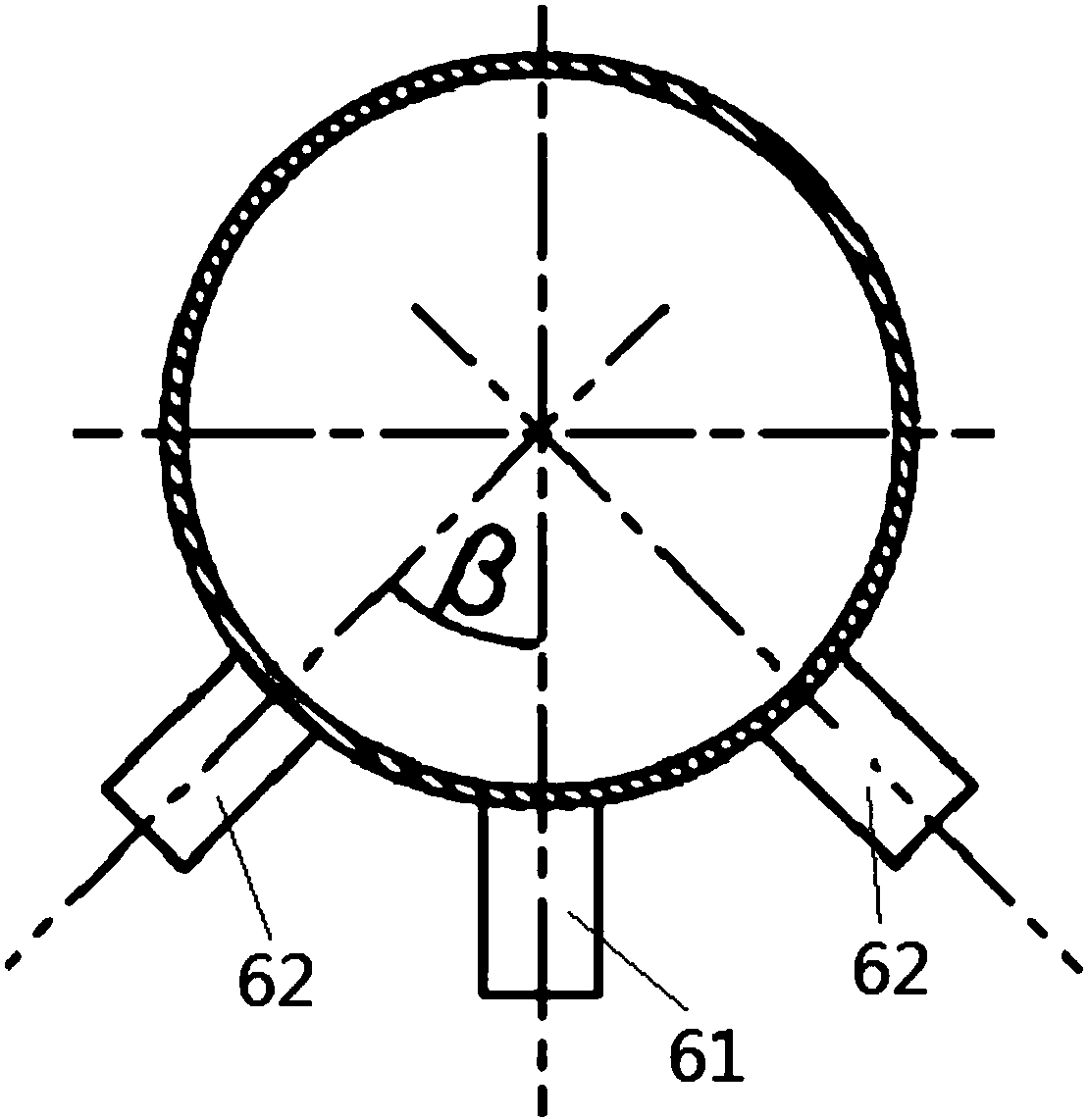

[0054] continue to refer figure 1 and figure 2 , according to an embodiment of the present invention, the gas distributor includes a gas riser 2, and the gas riser 2 is connected to the center of each layer of pipeline components. Such as figure 2 As shown in , each feed distribution pipe 3 is evenly distributed radially along the circumference of the gas riser 2 . In reactions comprising this gas distributor, said gas riser 2 extends along the longitudinal centerline of the reactor 1 . In this way, it can be ensured that the pressure and velocity of the gas entering each feed distribution pipe 3 are substantially equal, so that the distribution of the gas is uniform. A plurality of nozzles 6 are distributed on each feed distribution pipe 3, and these nozzles 6 can be arranged at equal intervals, or can be arranged in other ways, but preferably, the flow velocity of the gas ejected from each nozzle 6 should be as close as possible. quite.

[0055] Further, according to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com