Coaxial powder-feeding mouth for inner wall laser metling covering and alloying treatment of hold pieces

A laser cladding and alloying technology, applied in laser welding equipment, molten spraying, metal processing equipment, etc., can solve problems such as unsatisfactory cooling effect, difficult to circulate cooling, short circuit of cooling water, etc., and achieve good cooling effect, Excellent cooling effect and the effect of eliminating dead angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

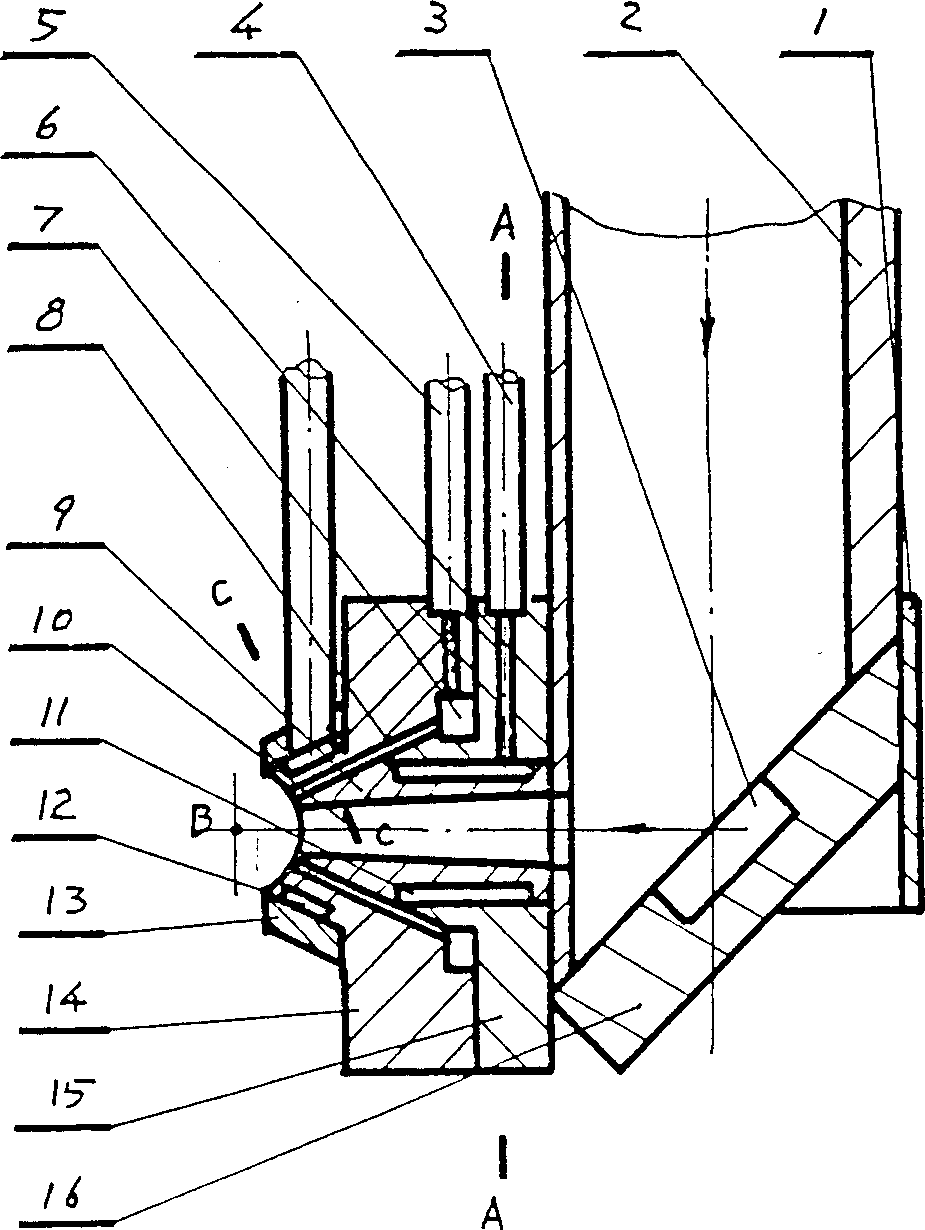

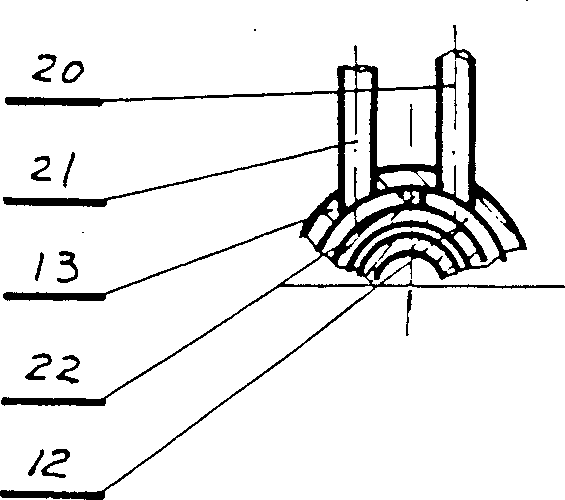

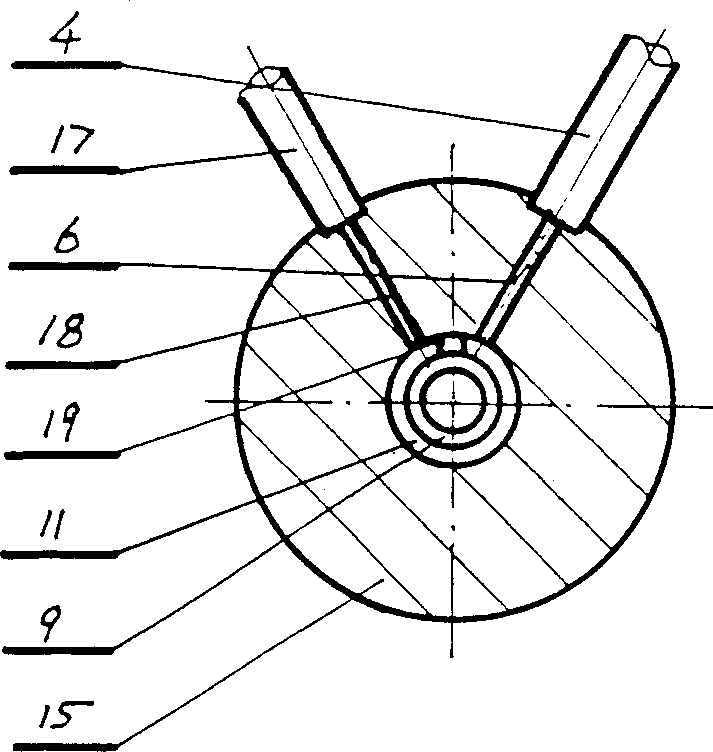

[0026] Example 1. A coaxial powder feeding nozzle for laser cladding and alloying of the inner wall of hole parts. It consists of laser channels, U-shaped clamps, outer rings, cone rings, cone sleeves, internal and external cooling water channels, and powder feeding channels. The laser channel is composed of a light guide tube, a cooling jacket, a reflector and an inner cone. The inner cooling water channel is composed of a water inlet pipe, a water inlet, an outlet pipe, an outlet, an inner annular water channel and a partition. The powder feeding channel is composed of a powder feeding pipe, an annular mixing chamber and a tapered ring groove. There are 4 powder feeding pipes and they are evenly distributed along the radial direction. The outer cooling water channel is composed of a water inlet pipe, a water outlet pipe, an outer annular water channel and a partition. The ends of the inner cone, the cone ring and the cone sleeve together form a spherical structure.

Embodiment 2

[0027] Example 2. A coaxial powder feeding nozzle for laser cladding and alloying of the inner wall of hole parts. It consists of laser channels, U-shaped clamps, outer rings, cone rings, cone sleeves, internal and external cooling water channels, and powder feeding channels. The laser channel is composed of a light guide tube, a cooling jacket, a reflector and an inner cone. The inner cooling water channel is composed of a water inlet pipe, a water inlet, an outlet pipe, an outlet, an inner annular water channel and a partition. The powder feeding channel is composed of a powder feeding pipe, an annular mixing chamber and a tapered ring groove. There are 2 powder feeding pipes and they are evenly distributed along the radial direction. The outer cooling water channel is composed of a water inlet pipe, a water outlet pipe, an outer annular water channel and a partition. The ends of the inner cone, the cone ring and the cone sleeve together form a spherical structure.

Embodiment 3

[0028] Example 3. A coaxial powder feeding nozzle for laser cladding and alloying of the inner wall of hole parts. It consists of laser channels, U-shaped clamps, outer rings, cone rings, cone sleeves, internal and external cooling water channels, and powder feeding channels. The laser channel is composed of a light guide tube, a cooling jacket, a reflector and an inner cone. The inner cooling water channel is composed of a water inlet pipe, a water inlet, an outlet pipe, an outlet, an inner annular water channel and a partition. The powder feeding channel is composed of a powder feeding pipe, an annular mixing chamber and a tapered ring groove. There are 8 powder feeding pipes and they are evenly distributed along the radial direction. The outer cooling water channel is composed of a water inlet pipe, a water outlet pipe, an outer annular water channel and a partition. The ends of the inner cone, the cone ring and the cone sleeve together form a spherical structure.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com