Bilateral opposite flushing inlet wet ammonia method for flue gas desulfurizing technology and device thereof

A technology of desulfurization device and desulfurization process, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, which can solve problems such as unfavorable reactions, low mass transfer efficiency, unfavorable spray tower gas-liquid mass transfer, etc., to achieve improved desulfurization Efficiency, elimination of dead corners of flue gas, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

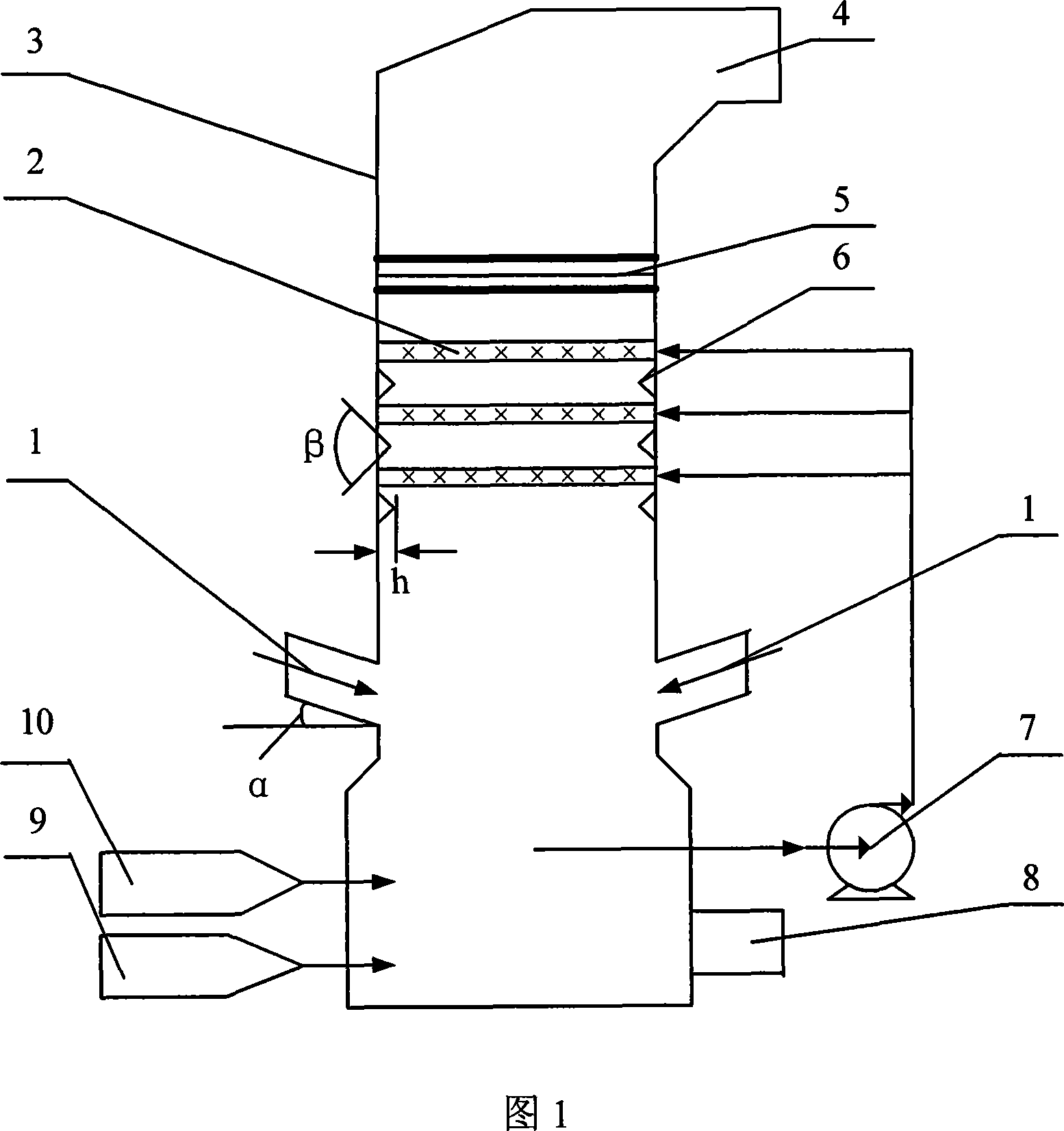

[0032] The following is a further detailed description of the process of the present invention and its device for the discharged flue gas of a coal-fired boiler unit in conjunction with the accompanying drawings:

[0033] The wet-type ammonia flue gas desulfurization device with double-sided hedging intake shown in Figure 1 has a desulfurization tower 3, the bottom of the desulfurization tower 3 is provided with a desulfurization by-product discharge port 8, and the top of the desulfurization tower 3 is provided with The clean flue gas outlet 4 and the desulfurization tower 3 are sequentially provided with a bottom desulfurizer slurry tank area, a lower flue gas input area, a middle flue gas diversion and desulfurizer spray area, and an upper flue gas demisting area from bottom to top. The desulfurization agent pulp pool area at the bottom of the desulfurization tower 3 is connected with an ammonia water supply device 10 and an air feed device 9 . Downwardly inclined flue gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com