Humidified and even flow pre-charged particulate matter enhanced removal system

A pre-charging and particulate matter technology, applied in power supply technology, electrostatic separation, steam flow control, etc., can solve the problems of difficult charging of ultrafine particles, uneven air distribution, and low removal efficiency, and achieve good working conditions and Adaptability of particle characteristics, optimization of smoke flow field distribution, and enhanced charging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

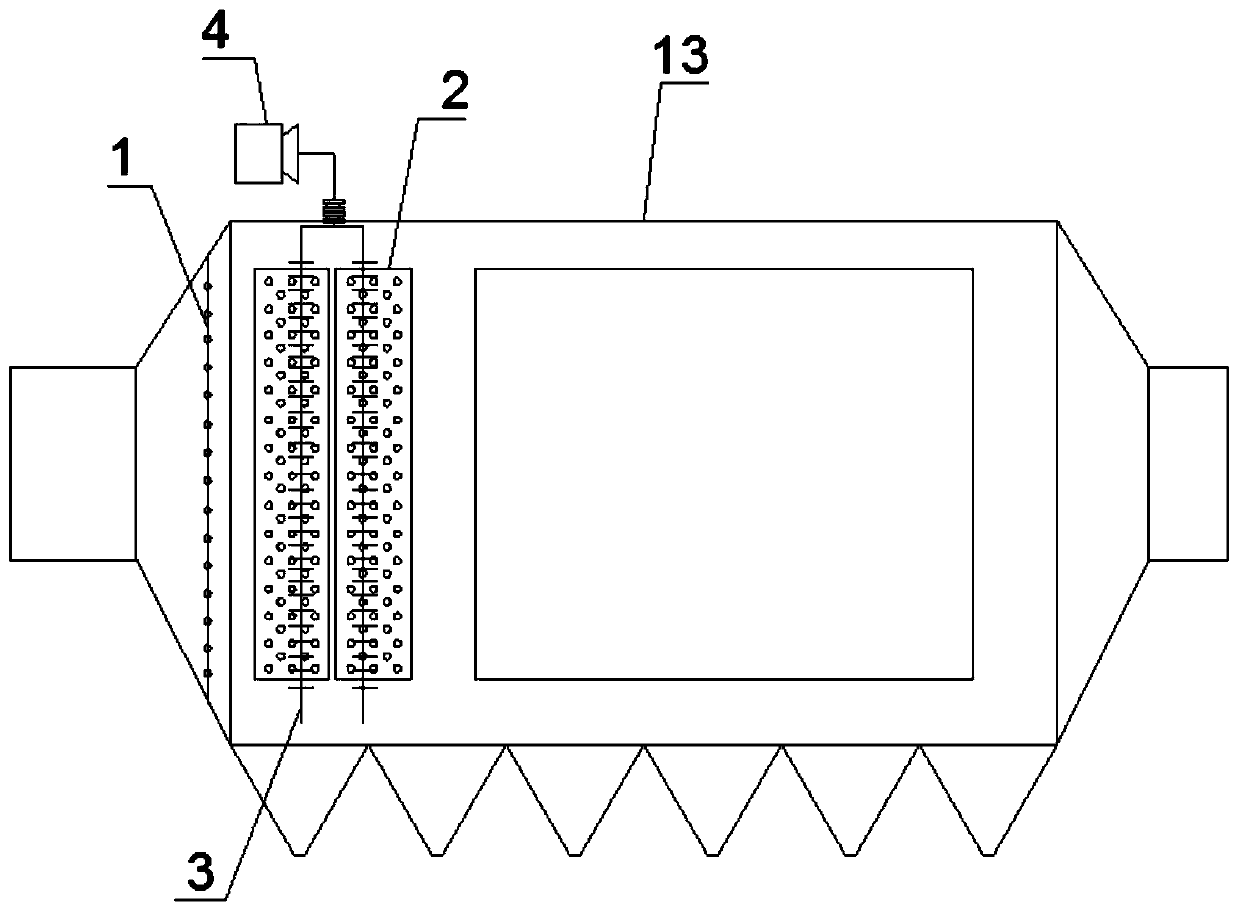

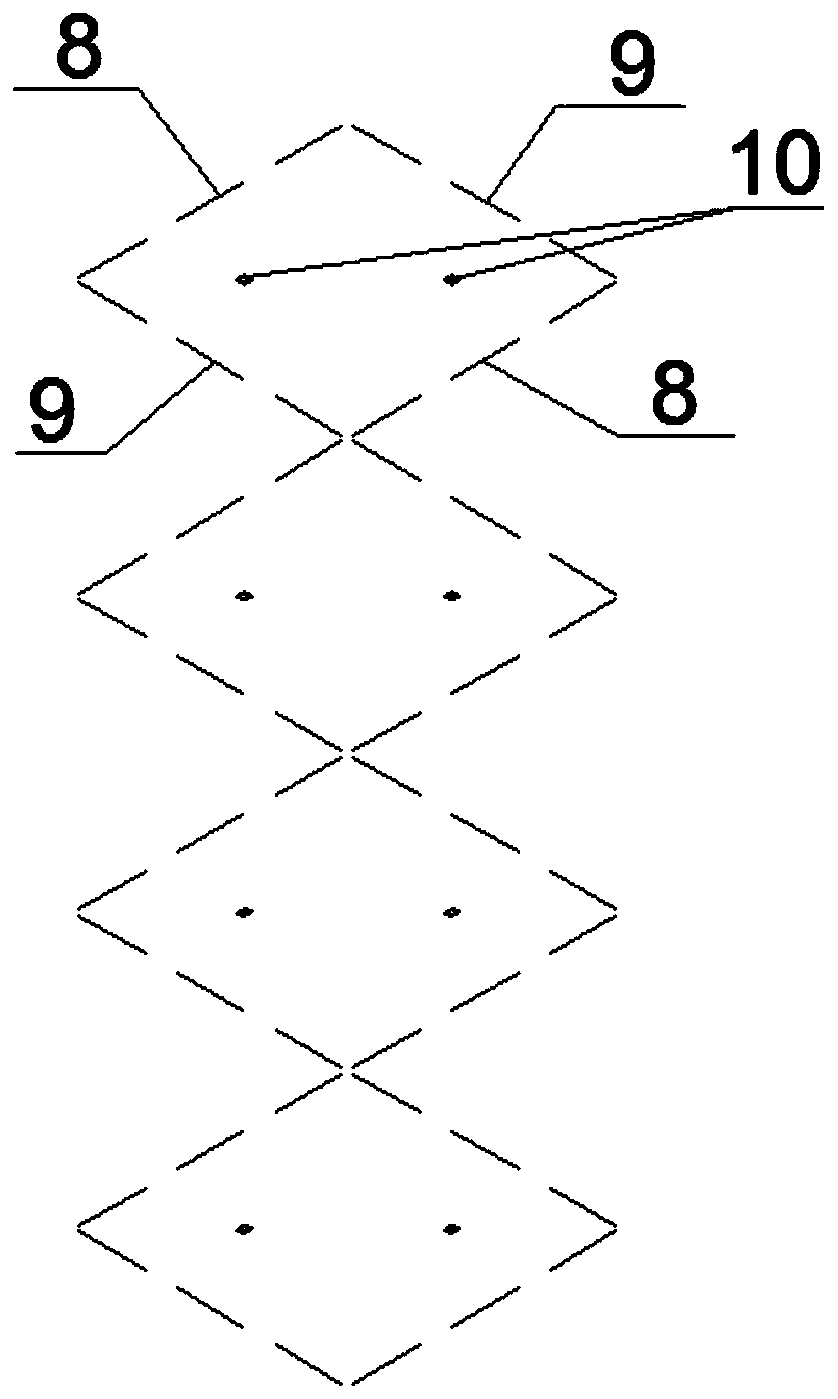

[0039] refer to Figure 1~4 , a humidified flow equalization pre-charged particulate matter enhanced removal system, said system sequentially includes a droplet injection device 1, a current equalization device 2 combining flow blocking and diversion, and a charge enhancement discharge device 3 along the flue gas direction , the distance between the droplet spraying device 1 and the flow equalizing device 2 combining flow blocking and guiding is 1000 mm.

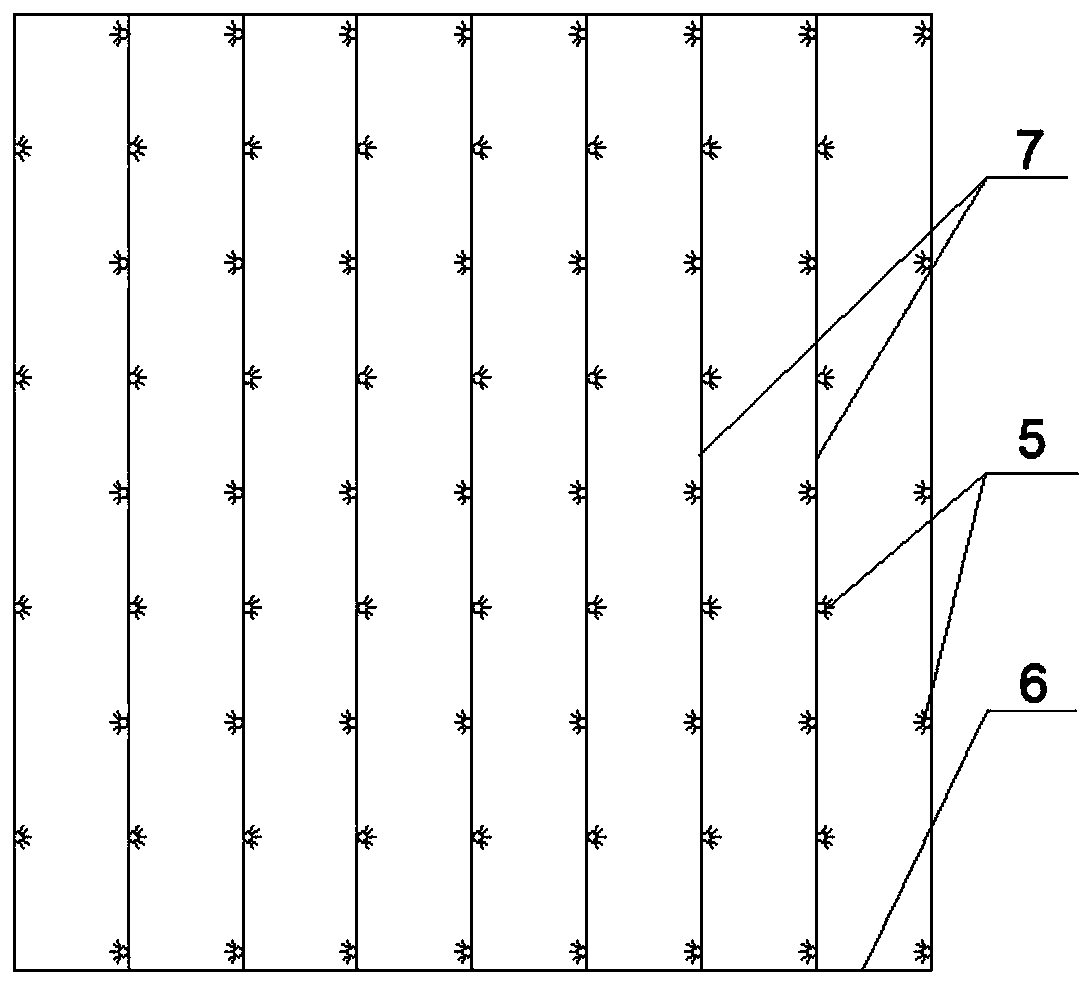

[0040] The droplet spraying device includes a nozzle 5 and a bracket 6, the bracket is arranged perpendicular to the direction of the flue gas, and parallel pipes 7 are installed on the bracket, and the nozzle 5 is arranged on the pipe 7; the pipe 7 is perpendicular to the smoke The gas direction is arranged, the distance between the pipes is not greater than the effective spraying distance of the nozzles 5, the spraying direction of the nozzles 5 is perpendicular to the smoke direction, the nozzles on a single pipe are even...

Embodiment 2

[0047] refer to Figure 2-6 , a humidified and even-flow pre-charged particulate matter enhanced removal system. According to the sequence of the flue gas flow, an ultra-fine droplet spraying device 1, a current-balancing device 2 combining flow blocking and diversion, and a charge-enhancing discharge device are respectively arranged. 3. The air flow first passes through the ultra-fine droplet injection device 1 and then through the flow equalization device 2 combining flow blocking and diversion. The distance between the ultrafine droplet injection device 1 and the flow equalization device 2 combining flow resistance and flow diversion is 500mm.

[0048] The droplet spraying device includes a nozzle 5 and a bracket 6, the bracket is arranged perpendicular to the direction of the flue gas, and parallel pipes 7 are installed on the bracket, and the nozzle 5 is arranged on the pipe 7; the pipe 7 is perpendicular to the smoke The gas direction is arranged, the distance between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com