Combined layout structure of flue gas system with six outlets of dust collector and double row induced draft fan

A technology for arranging structure and induced draft fan, which is applied in the direction of induced draft, exhaust gas device, lighting and heating equipment, etc., can solve the problems of difficulty in making full use of space, unreasonable equipment layout, large layout area, etc., and saves the length of pipes. , The effect of optimizing the flue gas flow field and reducing the footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

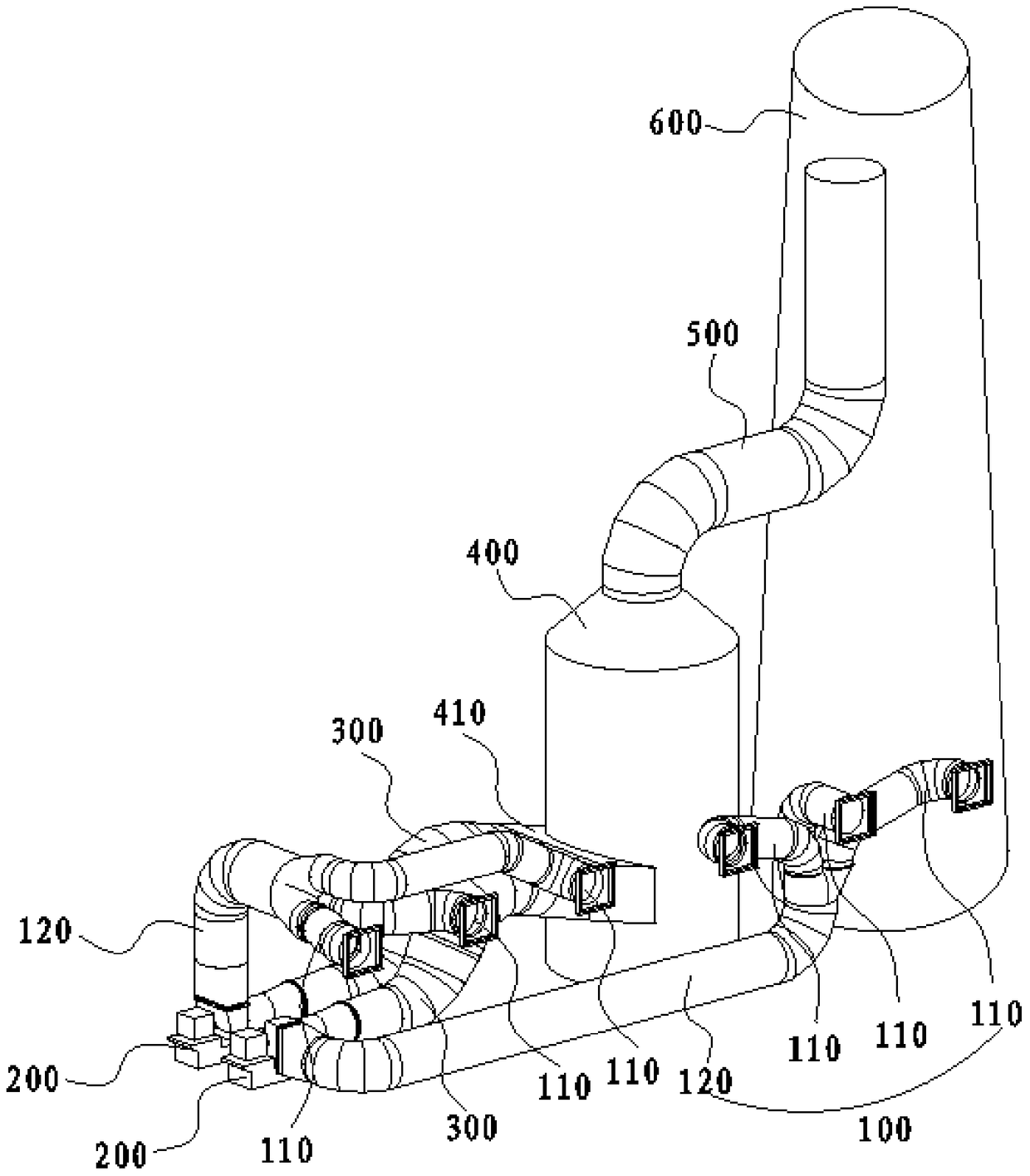

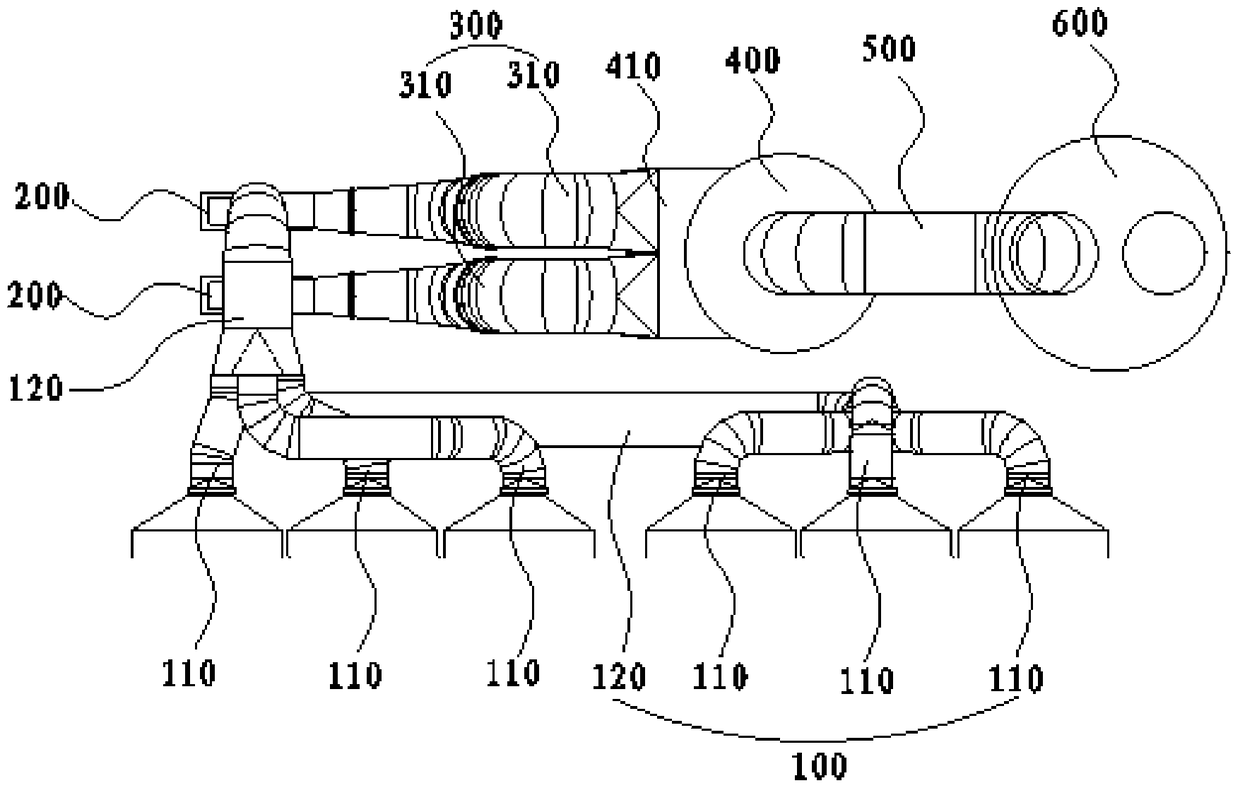

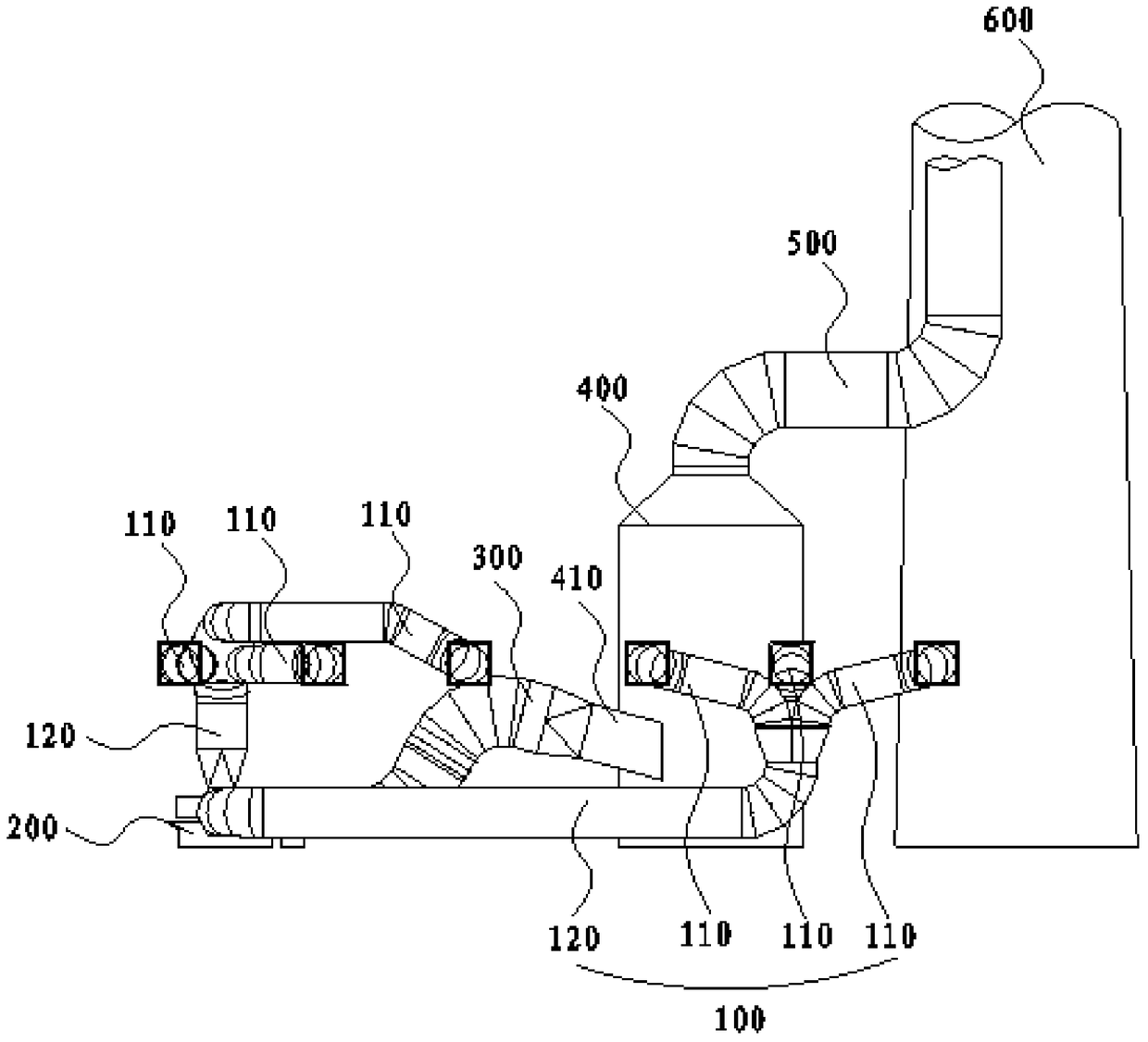

[0028] Such as figure 1 As shown, a joint layout structure of the flue gas system with six outlets of the dust collector and the flue gas system behind the double-row induced draft fan (that is, the arrangement structure of various equipment arranged behind the dust collector with six outlets), including the connection with the six outlets of the dust collector The double-row induced draft fan 200 (that is, two induced draft fans arranged horizontally and side by side), the desulfurization absorption tower 400 connected to the double-row induced draft fan 200, and the chimney 600 connected to the desulfurization absorption tower 400, and the double-row induced draft fans connected in sequence The center lines of the induced draft fan 200, the desulfurization absorption tower 400 and the chimney 600 are all located on the same plane. That is, the proje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com